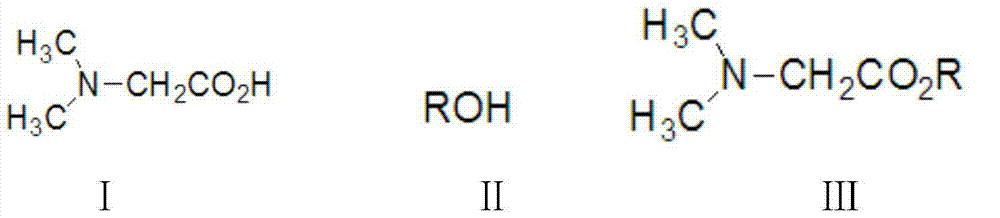

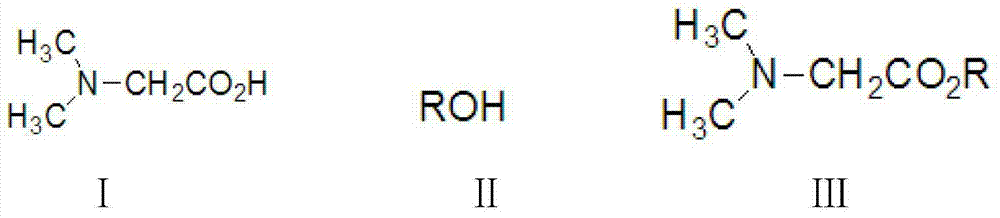

Preparation method of N,N-dimethyl glycine ester based on silica gel sulfonic acid serving as catalyst

A technology of dimethylglycine ester and dimethylglycine, which is applied in the field of chemical industry, can solve the problems of cumbersome operation and increased synthesis reaction cost, and achieve the effects of simple treatment, reduction of waste generation, and production cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Synthesis of N,N-dimethylglycine

[0031] Hydroxyacetonitrile method: at room temperature, add 1000 grams of 40% hydroxyacetonitrile aqueous solution to the autoclave, then pass through 1435 grams of 33% dimethylamine aqueous solution, then raise the temperature to 60°C, and the pressure reaches 7 kg (mPa), and react for 30 After 12 minutes, stop the reaction, transfer the reaction solution to a 3000ml flask, add 786 grams of 50% potassium hydroxide aqueous solution in the reaction solution, and incubate at 80°C for 5 hours to obtain N,N-dimethylglycinate Ammonia solution, deamination to obtain N,N-dimethylglycine salt solution, and then add 37% hydrochloric acid to adjust the pH to 5.0 to obtain a mixture of N,N-dimethylglycine and potassium chloride. Add 8 grams of activated carbon for decolorization, filter the activated carbon with suction, cool the filtrate to 10°C, crystallize, and centrifuge to remove potassium chloride crystals, and crystallize and pu...

Embodiment 2

[0032] Embodiment two N, the synthesis of N-dimethylglycine

[0033]Formaldehyde, sodium cyanide and dimethylamine three-component Strecker method: add 1000 grams of 37% formaldehyde aqueous solution and 2215 grams of 30% sodium cyanide aqueous solution to the reactor, and then slowly add 3363 grams of 33% dimethylamine aqueous solution dropwise, After the dropwise addition, raise the temperature to 80°C and react for 5 hours to obtain an ammonia solution of N,N-dimethylglycine sodium salt, deamination to obtain a solution of N,N-dimethylglycine sodium salt, and then add 98% sulfuric acid to adjust pH to 5.0, to obtain a mixture of N,N-dimethylglycine and sodium sulfate. Add 6 grams of activated carbon for decolorization, filter the activated carbon with suction, cool the filtrate to 10°C, crystallize, centrifuge to remove sodium sulfate crystals, and crystallize and purify the filtrate according to conventional methods to obtain 646 grams of N,N-dimethylglycine solid with a p...

Embodiment 3

[0034] Embodiment three: the preparation of catalyst silica gel sulfonic acid

[0035] Add 1000 grams of 200-300 mesh dry silica gel into the reactor, then add 2000 grams of dichloromethane, stir at room temperature, and slowly add a certain amount of chlorosulfonic acid. After the addition was complete, stirring was continued at room temperature for 2 hours, and the hydrogen chloride gas released was absorbed with water. Stand still and remove dichloromethane to obtain silica gel sulfonic acid with a certain amount of immobilized sulfonic acid, dry and analyze the immobilized amount of sulfonic acid to obtain catalyst silica gel sulfonic acid for future use. The mass ratio of the sulfonic acid to the silica gel by weight of chlorosulfonic acid is 15-40%.

[0036] catalyst Chlorosulfonic acid (g) Solid loading (mmol / g) Silica sulfonic acid A 150 1.28 Silica sulfonic acid B 250 2.14 Silica sulfonic acid C 400 3.40

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com