Technology for treating high-concentration wastewater of tobacco sheet industry by electrochemical oxidation method

A tobacco flake, electrochemical technology, applied in the field of high-concentration wastewater treatment process, can solve the problems of high operating costs, wastewater cannot meet the first-level discharge standard, and high chroma of effluent, so as to reduce operating costs, improve biochemical ability, The effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A well-known domestic inland tobacco sheet company produces 5,000 tons of tobacco sheets annually, and produces 80 m3 of high-concentration organic wastewater per day. It takes 2 m3 of high-concentration organic wastewater every day. After testing, the COD ranges from 130,000 to 180,000 mg / l, and the pH value is 5~6, the chromaticity is greater than 3000 times.

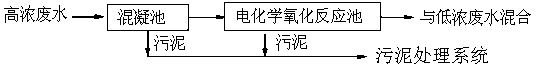

[0023] Use the treatment process of the present invention:

[0024] Step 1, the high-concentration organic wastewater enters the coagulation tank through the collection device, and coagulant and flocculant are added to the coagulation tank for coagulation treatment. The coagulant is polyaluminum chloride, and the flocculant is polyacrylamide. The sludge generated by the reaction is discharged into the sludge treatment system;

[0025] Step 2, the supernatant in step 1 enters the electrochemical oxidation reaction tank for oxidation treatment, controls the current density to 40 mA / cm2, and reacts for 20 minutes...

Embodiment 2

[0028] To simulate the production process of tobacco sheet factory in the laboratory, 0.5m3 of high-concentration wastewater is prepared every day, the range of COD is 70000~80000mg / l, the pH value is 5~6, and the chromaticity is more than 2000 times.

[0029] Using the treatment process of the present invention: step 1, the high-concentration organic wastewater enters the coagulation tank through the collection device, and adds coagulant and flocculant to the coagulation tank for coagulation treatment. The coagulant adopts iron sulfate, and the flocculant Using polyacrylamide, the sludge generated by the reaction is discharged into the sludge treatment system;

[0030] In step 2, the supernatant in step 1 enters the electrochemical oxidation reaction tank for oxidation treatment, and the current density is controlled to 50 mA / cm2 for 25 minutes. After the reaction, the supernatant is mixed with low-concentration wastewater and enters the low-concentration wastewater treatment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com