Treatment method of landfill leachate based on GY-3 type filler matrix

A landfill leachate, GY-3 technology, applied in the field of landfill leachate treatment, can solve the problems of fouling of concentrated water reuse equipment, high operation and maintenance costs, low reuse rate of produced water, etc., and achieve good hydraulic conductivity and Permeability, improve the ability to resist hydraulic shock, and reduce the effect of occupying an area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

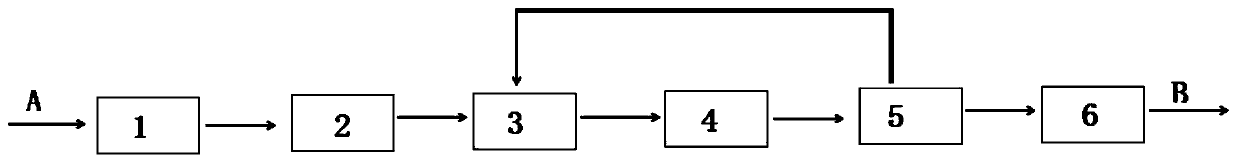

Image

Examples

Embodiment 1

[0049] GY-3 type packing matrix, the preparation process is as follows:

[0050] 1) Select the landfill that has been buried for 5 to 40 years, and after removing stones, broken glass, incompletely degraded rubber and plastic, wooden sticks, paper and other debris with particles larger than 10mm, the moisture content is 20 to 36%. mineralized waste; the abundances of Pseudomonas, Sphingomonas, Comamonadaceae and Hyphomicrobiaceae in the mineralized waste were as high as 12.73%, 12.29%, and 8.82% respectively. % and 6.40%.

[0051] 2) Choose an ellipsoid, with a particle size of 6-13mm and a bulk density of 0.9-1.5g / cm 3 , ceramsite with a porosity of 0.3-0.7;

[0052] 3) Mix the mineralized waste and ceramsite at a mass ratio of 1: (3~7), soak and stir in the nitrifying bacteria culture medium for 150 seconds, and mix well; every two days, replace with fresh nitrifying bacteria culture medium and mix well After culturing for 10 days, the primary packing matrix is complete...

Embodiment 2

[0057] The primary filler matrix preparation process is as follows:

[0058] 1) Select the landfill that has been buried for 5 to 40 years, and after removing stones, broken glass, incompletely degraded rubber and plastic, wooden sticks, paper and other debris with particles larger than 10mm, the moisture content is 20 to 36%. mineralized waste; the abundances of Pseudomonas, Sphingomonas, Comamonadaceae and Hyphomicrobiaceae in the mineralized waste were as high as 12.73%, 12.29%, and 8.82% respectively. % and 6.40%.

[0059] 2) Choose an ellipsoid, with a particle size of 6-13mm and a bulk density of 0.9-1.5g / cm 3 , ceramsite with a porosity of 0.3-0.7;

[0060] 3) Mix the mineralized waste and ceramsite at a mass ratio of 1: (3~7), soak and stir in the nitrifying bacteria culture medium for 150 seconds, and mix well; every two days, replace with fresh nitrifying bacteria culture medium and mix well After culturing for 10 days, the primary packing matrix is completed; t...

Embodiment 3

[0063] A filter bed, the filter bed, from top to bottom, sequentially comprises a water distribution pipe, a packing matrix layer made of the packing matrix described in Example 1, a supporting layer and a drainage pipe, and a ventilation pipe, the ventilation pipe Vertically and indirectly distributed inside the filter bed; the upper end of the ventilation pipe is higher than the surface of the filter bed, and the lower end passes through the packing matrix layer and extends to the supporting layer; the drainage pipe is arranged between the supporting layers; There are collection holes; the water distribution pipes are evenly distributed on the surface of the filter bed, distributed in parallel, with an inner diameter of 20mm, and the distance between two water distribution pipes is 1m; the ventilation pipes are evenly distributed in the filter bed, distributed in parallel, with an inner diameter of 10mm, The distance between two ventilation pipes is 1m; the drainage pipes are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com