Ingot-casting silicon powder with controllable grain size as well as preparation method and application thereof

A technology of silicon powder and ingot casting, which is applied in the field of solar-grade polysilicon materials, and can solve the problems of low surface oxidation of recycled silicon powder, easy melting of silicon powder, and low oxidation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

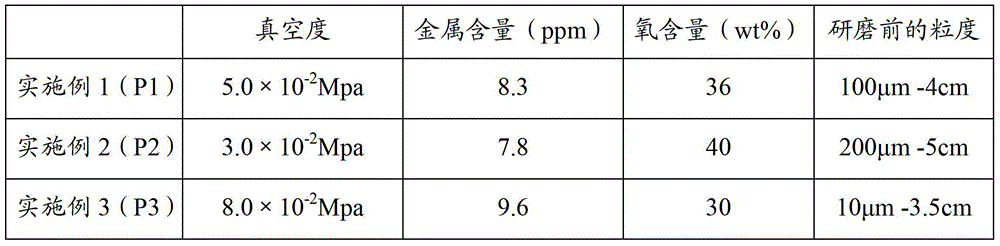

Embodiment 1

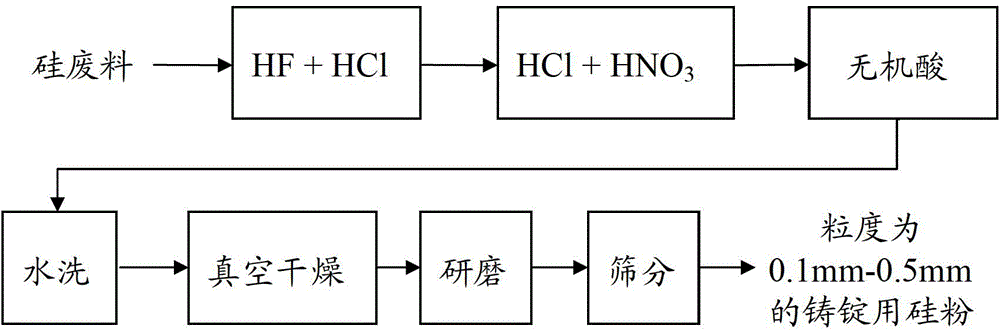

[0039] Combine as figure 1 As shown in the process flow chart of preparing silicon powder for ingot with controllable particle size, this embodiment provides a method for preparing silicon powder for ingot with controllable particle size, which includes the following steps:

[0040] S10. Disperse 20kg of silicon waste in 20L of water, then add 12L of hydrofluoric acid (49%) and 8L of hydrochloric acid (36.5%), fully stir the reaction for 30 minutes, and centrifuge to obtain 14kg of primary silicon powder;

[0041] S20. Disperse the primary silicon powder obtained from S10 in 44L of water, add 10L of hydrochloric acid (36.5%) and 2L of nitric acid (68%), stir and disperse for 1 hour, soak for another 8 hours, and centrifuge to obtain 13.5kg of primary Silicon powder

[0042] S30. Re-disperse the primary silicon powder obtained by S20 centrifugation in 20L of pure water, add 2L of hydrochloric acid (36.5%), stir and disperse for 1 hour, then centrifuge and wash the remaining acid solut...

Embodiment 2

[0047] A method for preparing silicon powder for ingot casting with controllable particle size includes the following steps:

[0048] S10. Disperse 40kg of silicon waste in 36.5L of water, then add 1.2L of hydrofluoric acid (49.5%) and 2.3L of hydrochloric acid (38%), fully stir the reaction for 120 minutes, and centrifuge to obtain 30kg of primary silicon powder ;

[0049] S20. Disperse the primary silicon powder obtained from S10 in 37.6L of water, add 0.8L of hydrochloric acid (38%) and 1.6L of nitric acid (67%), stir and disperse for 2 hours, soak for another 10 hours, and filter under reduced pressure. Obtain 29.5 kg of primary silicon powder;

[0050] S30. Re-disperse the primary silicon powder obtained by S20 centrifugation in 29.2L of pure water, add 0.3L of nitric acid (67%), stir and disperse for 2 hours, then filter under reduced pressure and wash the remaining acid with pure water 2 Secondary to neutral pH;

[0051] S40, repeat step S30 4 times to obtain 27.8kg of primar...

Embodiment 3

[0054] A method for preparing silicon powder for ingot casting with controllable particle size includes the following steps:

[0055] S10. Disperse 3kg of silicon waste in 55L of water, then add 4.5L of hydrofluoric acid (49%) and 0.5L of hydrochloric acid (36%), fully stir the reaction for 10 minutes, and centrifuge to obtain 2.25kg of primary silicon powder ;

[0056] S20. Disperse the primary silicon powder obtained from S10 in 41L of water, add 3.3L of hydrochloric acid (36%) and 0.3L of nitric acid (65%), stir and disperse for 0.5 hours, soak for another 0.5 hours, and centrifuge to obtain 2.15 kg primary silicon powder;

[0057] S30. Re-disperse the primary silicon powder obtained by S20 centrifugation in 42.4L of pure water, add 0.6L of sulfuric acid (98%), stir and disperse for 0.5 hours, then centrifuge and wash the remaining acid with pure water 3 times To neutral pH;

[0058] S40. Repeat step S30 5 times to obtain 2kg of primary silicon powder;

[0059] S50. Then put the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com