Wet method used for extracting products from low-grade complex material containing tellurium and selenium

A low-grade, all-wet technology, applied in binary selenium/tellurium compounds, etc., can solve the problems of low production efficiency, long operation cycle, incomplete roasting, etc., and achieve the effect of high grade, effective separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

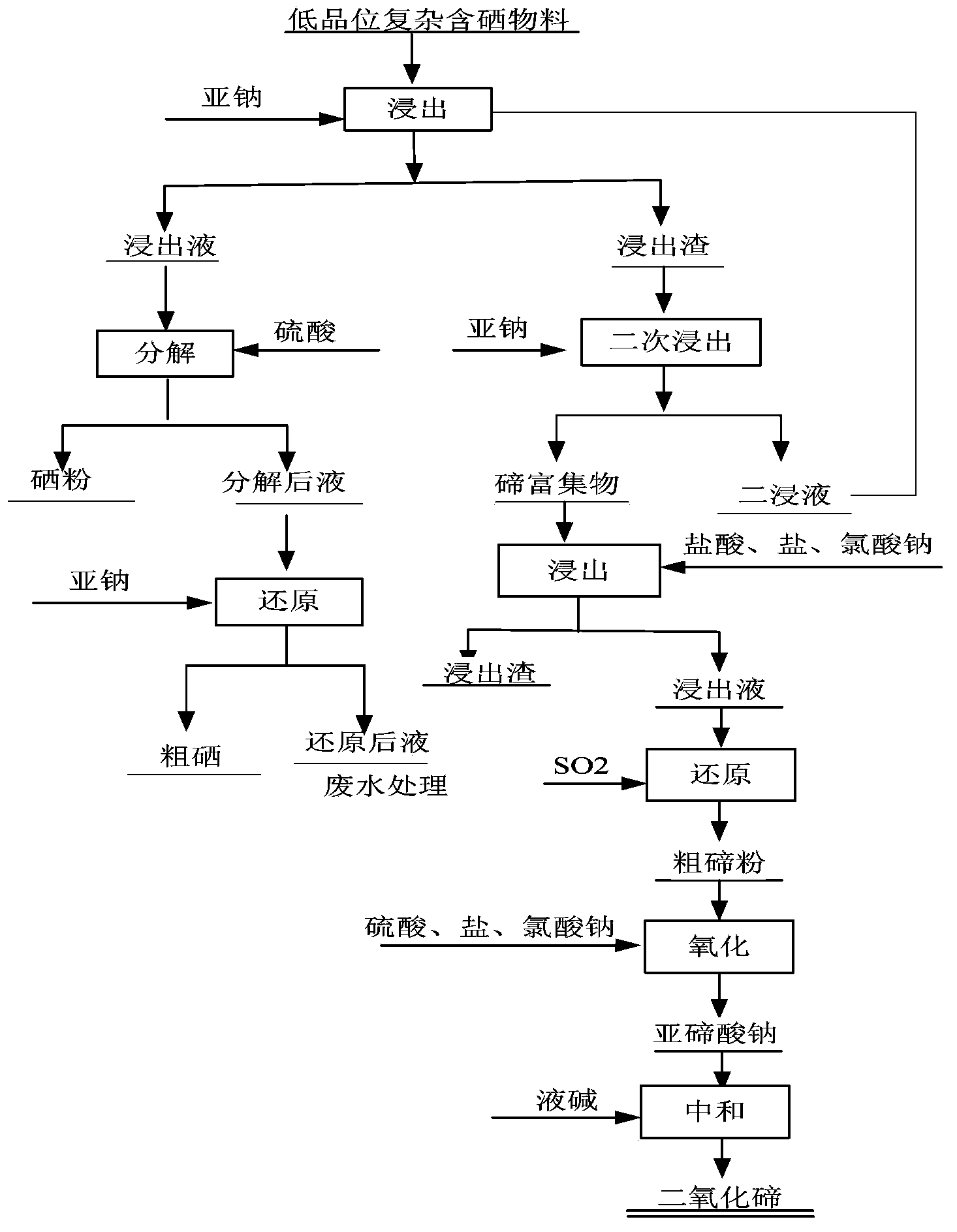

Image

Examples

Embodiment 1

[0024] Sodium leaching process: The chemical composition of low-grade complex selenium materials is: Se11.72%, Zn1.41%, Te2.97%, Fe1.16%, according to the liquid-solid ratio of 4:1, water and selenium-containing materials are added to the reaction In the tank, stir, add caustic soda at a concentration of 8.0g / L, add sodium nitrate at a concentration of 120g / L, heat up to 85°C, and react for 4 hours. Secondary leaching, the secondary leaching solution is used as the primary leaching mother liquor, the secondary leaching slag can be sent to sulfide roasting to recover residual selenium, and the primary leaching solution is sent to the decomposition process. The leaching rate of selenium is 95.21%, and tellurium basically stays in the slag phase and enters the next step of recovery.

[0025] Decomposition and generation process: add 10g / L sulfuric acid to the primary leaching solution under stirring conditions, adjust the acidity to PH: 2, control the temperature at 85°C, and the...

Embodiment 2

[0032] Sodium leaching process: the chemical composition of low-grade complex selenium materials is: Se11.72%, Zn1.41%, Te2.97%, Fe1.16%, water and selenium-containing materials are added to the reaction tank according to the liquid-solid ratio of 5:1 During the process, stir, add caustic soda at a concentration of 6.0g / L, add sodium nitrate at a concentration of 150g / L, heat up to 65°C, and react for 8 hours. The secondary leaching, the secondary leaching solution is used as the primary leaching mother liquor, the secondary leaching slag can be sent to sulfide roasting to recover residual selenium, and the primary leaching solution is sent to the decomposition process. The selenium leaching rate was 95.34%, and the tellurium basically remained in the slag phase and entered the next step of recovery.

[0033]Decomposition process: add 30g / L sulfuric acid to the primary leaching solution under stirring conditions, adjust the acidity to PH: 4, control the temperature at 65°C, an...

Embodiment 3

[0040] Sodium leaching process: the chemical composition of low-grade complex selenium materials is: Se11.72%, Zn1.41%, Te2.97%, Fe1.16%, water and selenium-containing materials are added to the reaction tank according to the liquid-solid ratio of 6:1 During the process, stir, add caustic soda at a concentration of 10.0g / L, add sodium nitrate at a concentration of 200g / L, heat up to 95°C, and react for 10 hours. The secondary leaching, the secondary leaching solution is used as the primary leaching mother liquor, the secondary leaching slag can be sent to sulfide roasting to recover residual selenium, and the primary leaching solution is sent to the decomposition process. The selenium leaching rate was 95.06%, and the tellurium basically remained in the slag phase and entered the next step of recovery.

[0041] Decomposition process: add 50g / L sulfuric acid to the primary leaching solution under stirring conditions, adjust the acidity to PH: 6, control the temperature at 50°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com