Machining tool of part with multiple stepped holes and working method thereof

A multi-step and tooling technology, used in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve problems such as inability to apply to workpieces of different sizes, difficulty in ensuring workpiece flatness requirements, and affecting the depth of step holes. High versatility, high consistency, and the effect of reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

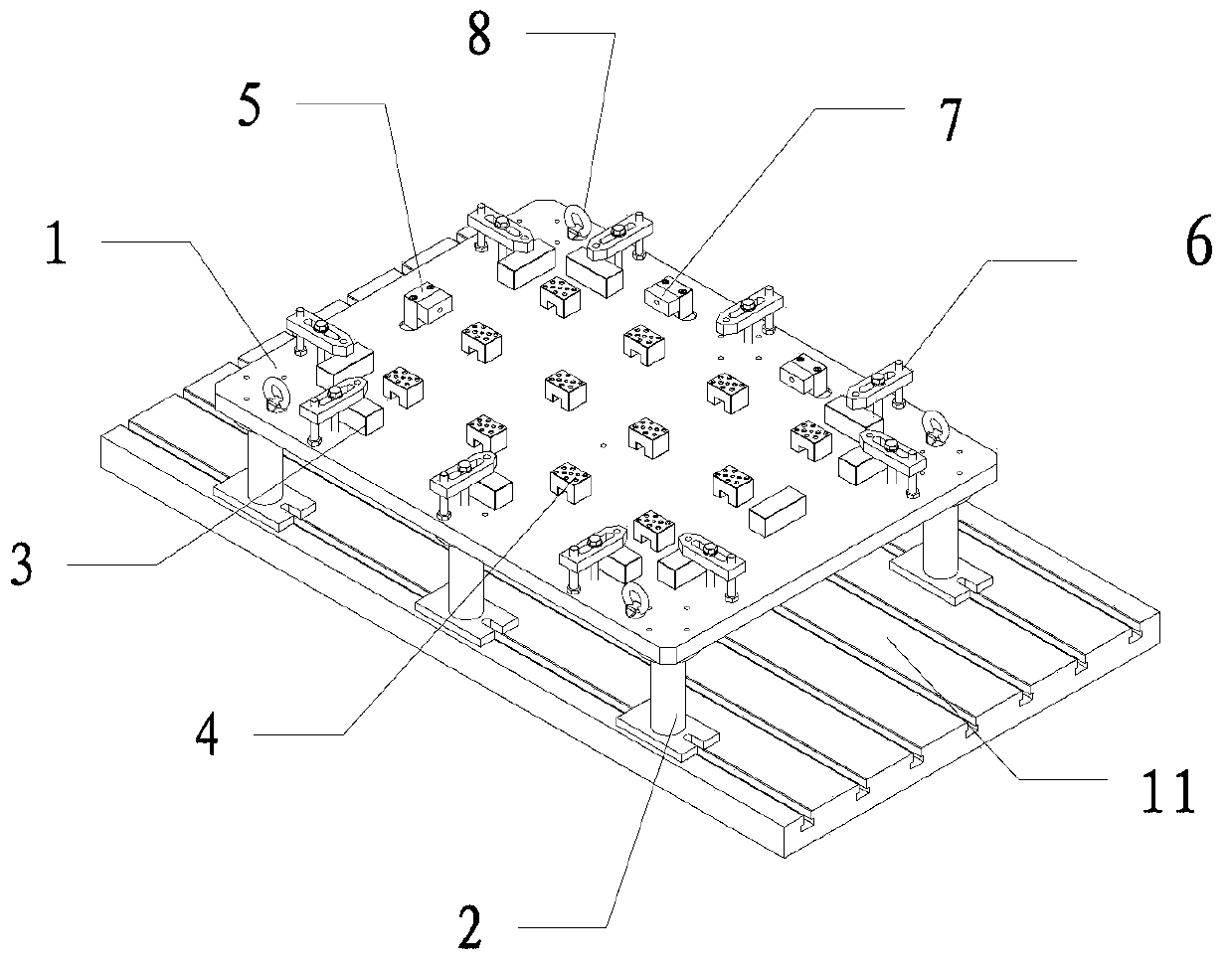

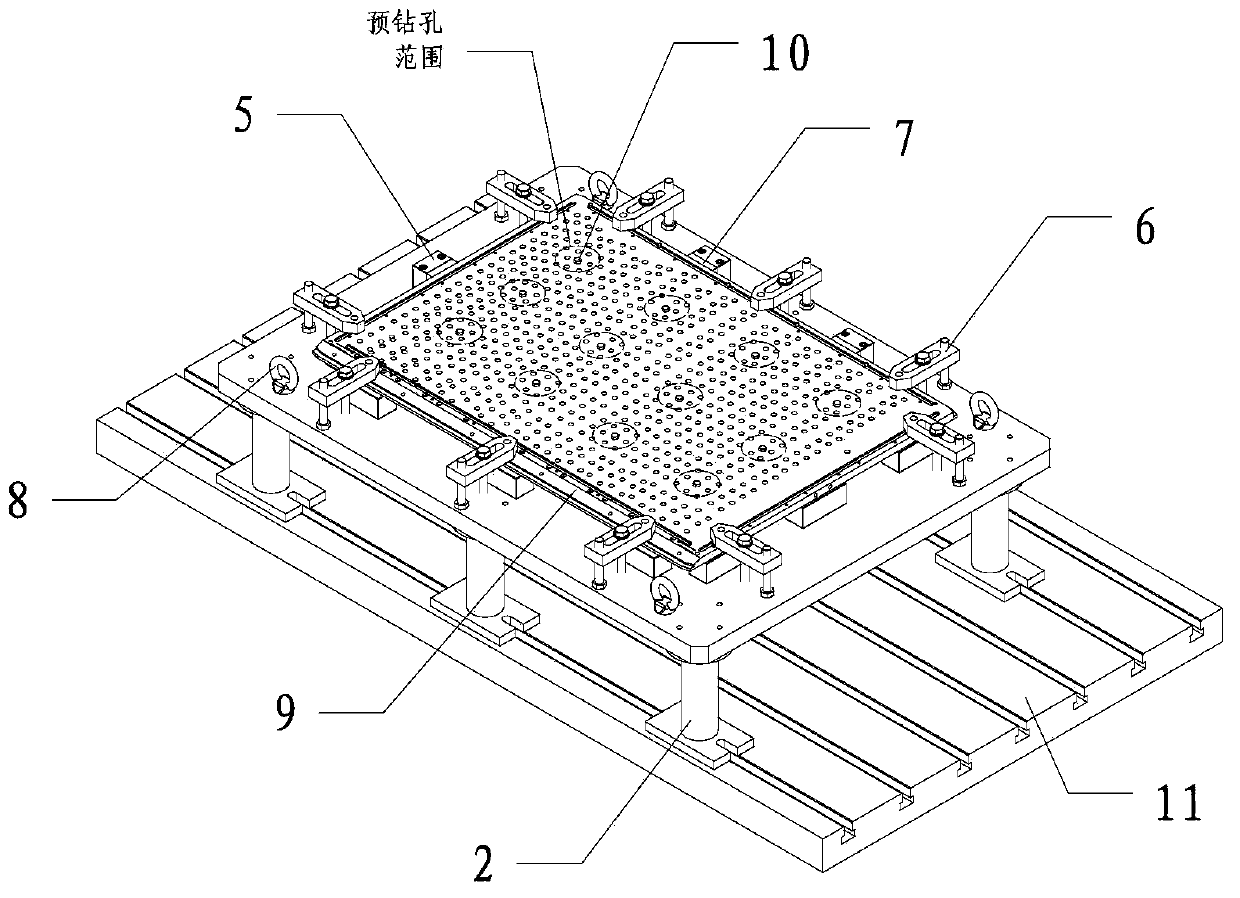

[0020] Embodiment: a kind of processing tooling of multi-step hole type parts (see figure 1 , figure 2 ), which is characterized in that it includes a bottom bracket 1, a four-side pad 3, a middle pad 4, a positioning block 5 and a splint 6; 3 are respectively fixed on the four sides above the bottom bracket 1; the middle spacer 4 is fixed on the bottom bracket 1; the splint 6 is fixed with the bottom bracket 1 by bolts, and the workpiece 9 is tightened and loosened by tightening and loosening the screws.

[0021] The bottom support 1 is connected to the workbench 11 through the support column 2 . (See figure 1 , figure 2 )

[0022] The positioning block 5 is connected with compensation blocks 7 of different thicknesses to position workpieces of different sizes. (See figure 1 , figure 2 )

[0023] The middle pad 4 is an inverted "concave" part, and there is a threaded hole for connecting with the workpiece 9 in the middle of the middle pad 4, and a shallow hole is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com