Method for preparing strong antioxidative peptide by using peanut meal

An anti-oxidative peptide and peanut meal technology, which is applied in the fields of application, protein composition of vegetable seeds, protein food processing, etc., can solve the problems of increased disulfide bonds, increased hydrophobic value, low hydrolysis efficiency, etc., to achieve reduced viscosity, Short heating time and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

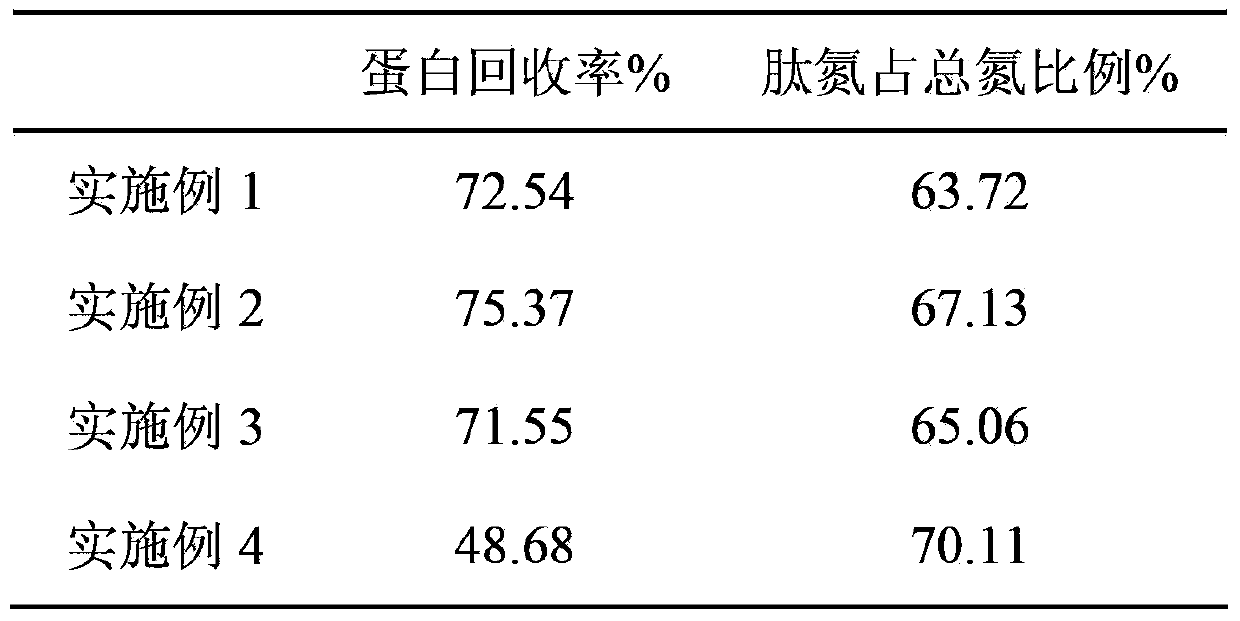

Examples

Embodiment 1

[0035] A method for preparing strong antioxidant peptides from peanut meal, comprising the following steps:

[0036] (1) Pretreatment of raw materials: Mix citric acid buffer solution (pH value 4.0) and peanut meal at a mass ratio of 1:1, then heat in a microwave oven under the heating conditions of 1000W and 100s; after the material is cooled, use powder The material is pulverized by a machine, and then passed through a 30-mesh sieve to obtain a modified peanut meal powder.

[0037] (2) Surfactant-assisted enzymatic hydrolysis of peanut meal: add water 5 times the mass of powdered peanut meal, adjust the pH value of the peanut meal slurry to 8.0 with 1mol / L sodium hydroxide, and add alkaline Protease (Alcalase2.4L), 0.6% cellulase and 0.032% Tween 80, carried out enzymatic hydrolysis reaction at 55°C, controlled the degree of hydrolysis to 5% by pH-Stat method, inactivated the enzyme at 90°C for 30min, and centrifuged to obtain The supernatant is the enzymatic hydrolysis sol...

Embodiment 2

[0043] A method for preparing strong antioxidant peptides from peanut meal, comprising the following steps:

[0044] (1) Pretreatment of raw materials: mix succinic acid buffer solution (pH value 4.5) and peanut meal at a mass ratio of 2:1, then heat in a microwave oven under the heating conditions of 1200W and 80s; after the material is cooled, use powder The material is pulverized by a machine, and then passed through a 30-mesh sieve to obtain a modified peanut meal powder.

[0045] (2) Surfactant-assisted enzymatic hydrolysis of peanut meal: add water 7 times the mass of powdered peanut meal, adjust the pH value of the peanut meal slurry to 7.0 with 1mol / L sodium hydroxide, and add papain according to 1.2% of the substrate mass (Papain), 0.75% cellulase and 0.05% Span 40, carried out enzymatic hydrolysis reaction at 50°C, controlled the degree of hydrolysis to 7% by pH-Stat method, inactivated the enzyme at 95°C for 20min, and centrifuged to obtain the supernatant: Enzyme ...

Embodiment 3

[0051] A method for preparing strong antioxidant peptides from peanut meal, comprising the following steps:

[0052] (1) Pretreatment of raw materials: mix malic acid buffer solution (pH value 5.0) and peanut meal at a mass ratio of 1.5:1, then heat in a microwave oven under the heating conditions of 800W and 200s; after the material is cooled, use powder The material is pulverized by a machine, and then passed through a 30-mesh sieve to obtain a modified peanut meal powder.

[0053] (2) Surfactant-assisted enzymatic hydrolysis of peanut meal: add water 8 times the mass of powdered peanut meal, adjust the pH value of peanut meal slurry to 7.0 with 1mol / L sodium hydroxide, and add compound protease according to 1.2% of the substrate mass (Protamex), 0.68% cellulase and 0.045% PEG-6000, carry out enzymatic hydrolysis reaction at 55°C, control the degree of hydrolysis to 6% by pH-Stat method, inactivate the enzyme at 95°C for 20min, and centrifuge to obtain the supernatant: Enzy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com