Surface treatment method for metal member and metal member obtained by same

A technology of metal parts and surface treatment, applied in the direction of surface reaction electrolytic coating, coating, electrolytic coating, etc., can solve the problems of not being able to form with high quality, rupture of anodic oxide film, high treatment cost, etc. Excellent adhesion and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

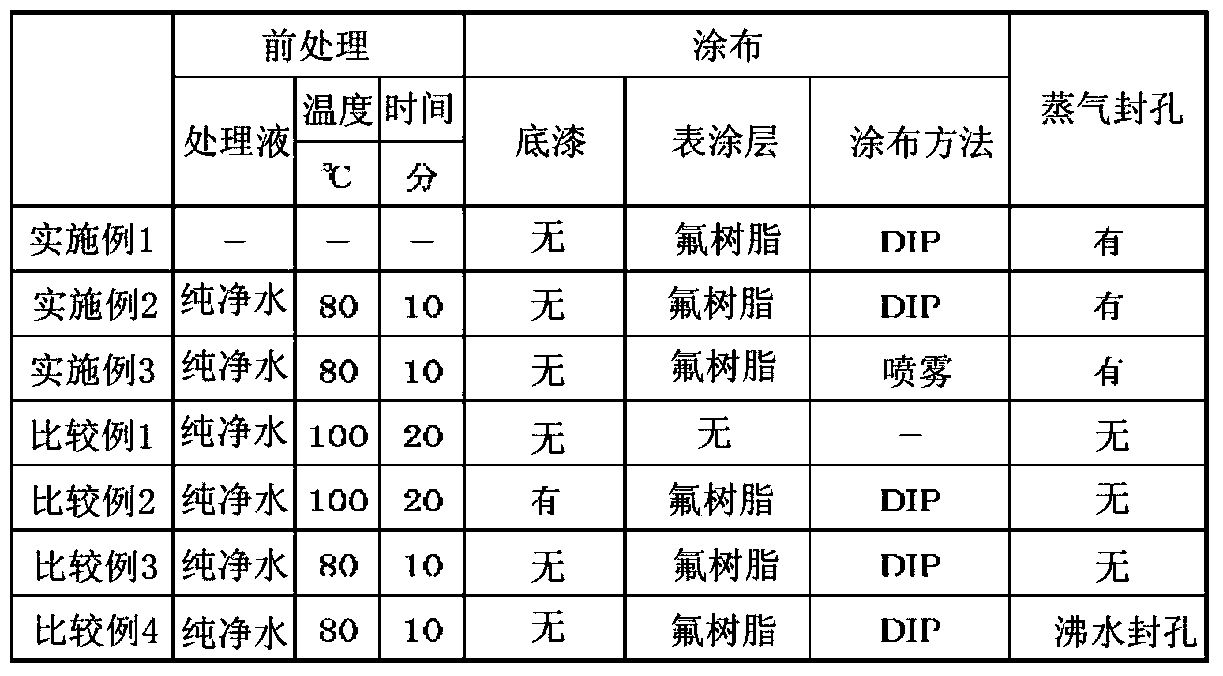

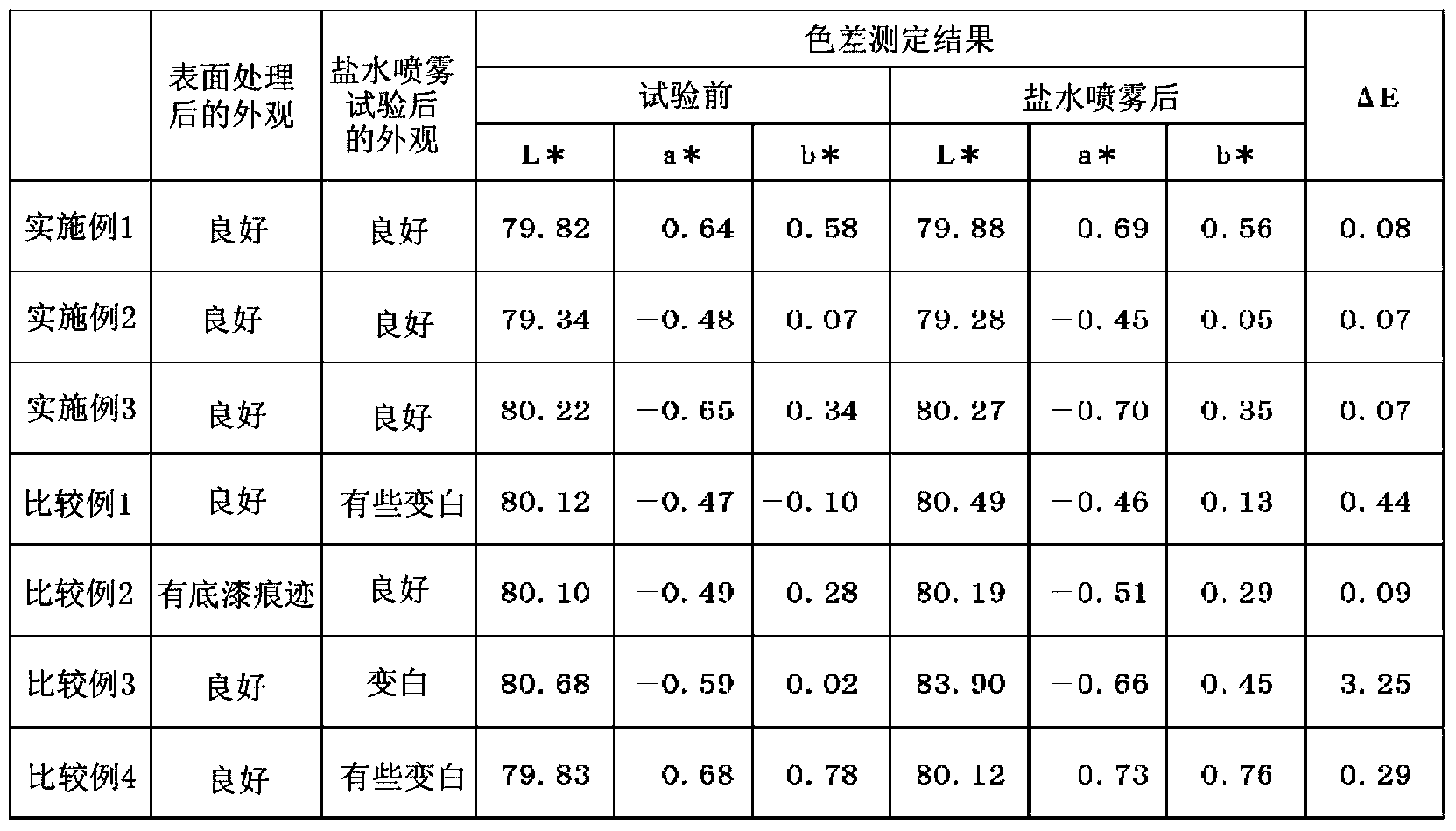

[0053] Example 1 is to wash with water after forming the anodized film, and Example 2 is to use pure water to perform a semi-sealing treatment (washing) at 80° C. for 10 minutes after forming the anodized film. Both of Examples 1 and 2 are then It was immersed in a solution obtained by dissolving a fluorine-based polymer in a fluorine-based solvent (Noda Sculin Co., Ltd., trade name OPC-800), and extracted.

[0054] In contrast to the immersion and extraction in the fluoropolymer solution in Examples 1 and 2, in Example 3, the solution was sprayed on the surface.

[0055] Although the thickness of the fluorine-based polymer attached to the surface of the treated product taken out after immersion could not be measured, it was estimated to be on the level of about 10 nm.

[0056] In Examples 1 to 3, a sealing treatment was performed for 20 minutes using steam at 150°C.

[0057]In addition, the conditions for steam sealing treatment can be normal pressure, but since the time of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com