Semi-finished product made of aluminium alloy having improved microporosity and manufacturing process

A technology of semi-finished products and aluminum alloys, applied in the field of semi-finished products made of aluminum alloys, which can solve the problems of reduced porosity, inconvenient installation of ultrasonic heads, and reduced hydrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

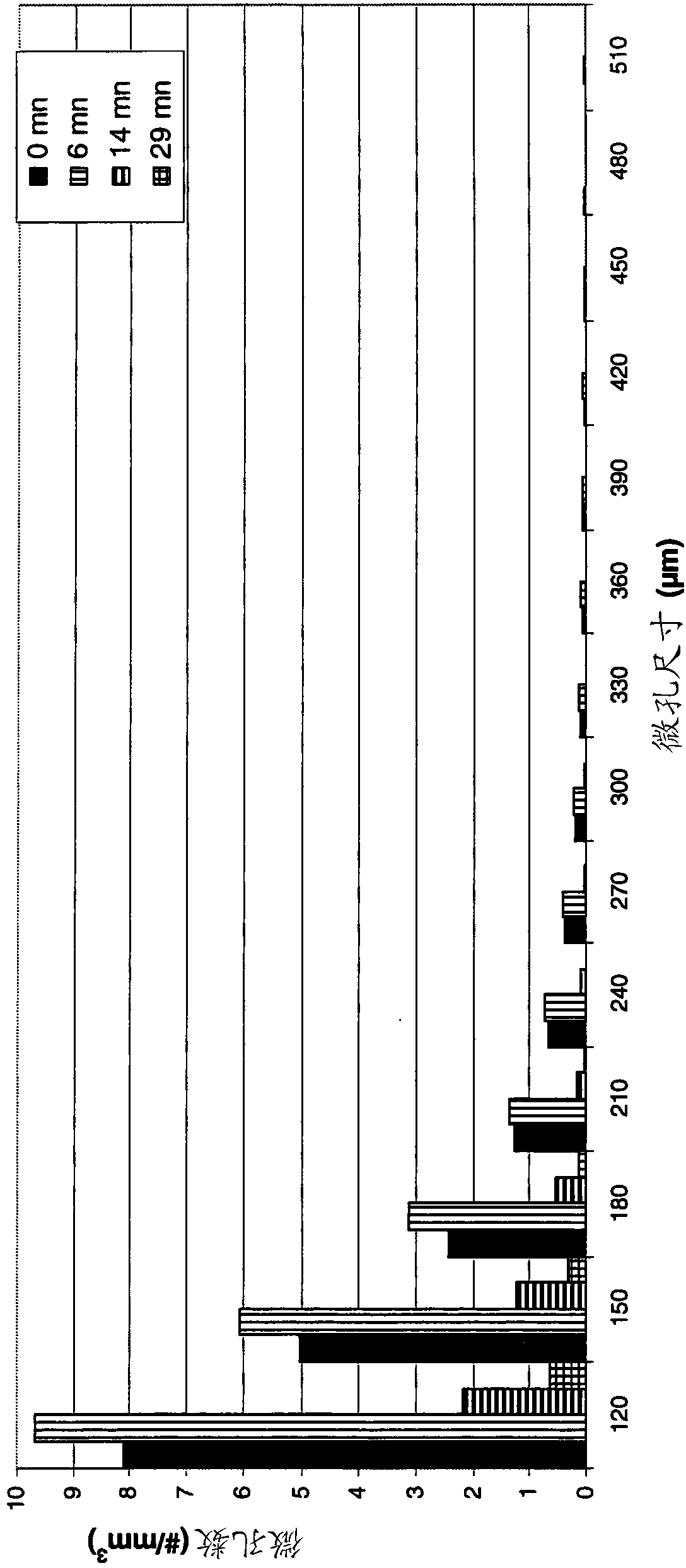

[0082] In this example, 16 kg of aluminum in the form of alloy AA5182 were melted in a crucible. The molten metal was kept at a temperature of 700+5°C during the test. Use Alscan TM The device measures the hydrogen content, which is always used outside of the sonication cycle so as not to interfere with the operation of the probe. The surface of the molten metal was purged permanently with argon at a rate of 5 l / min. No degassing or stirring was performed.

[0083]Sonication was performed at a frequency of 18 kHz with a 500 W ultrasonic transmitter. Samples were collected a few minutes after each treatment. Treatment time is considered cumulatively: the first 2-minute treatment is performed; the second 4-minute treatment is performed, which corresponds to 2+4=6 minutes of treatment time, and so on.

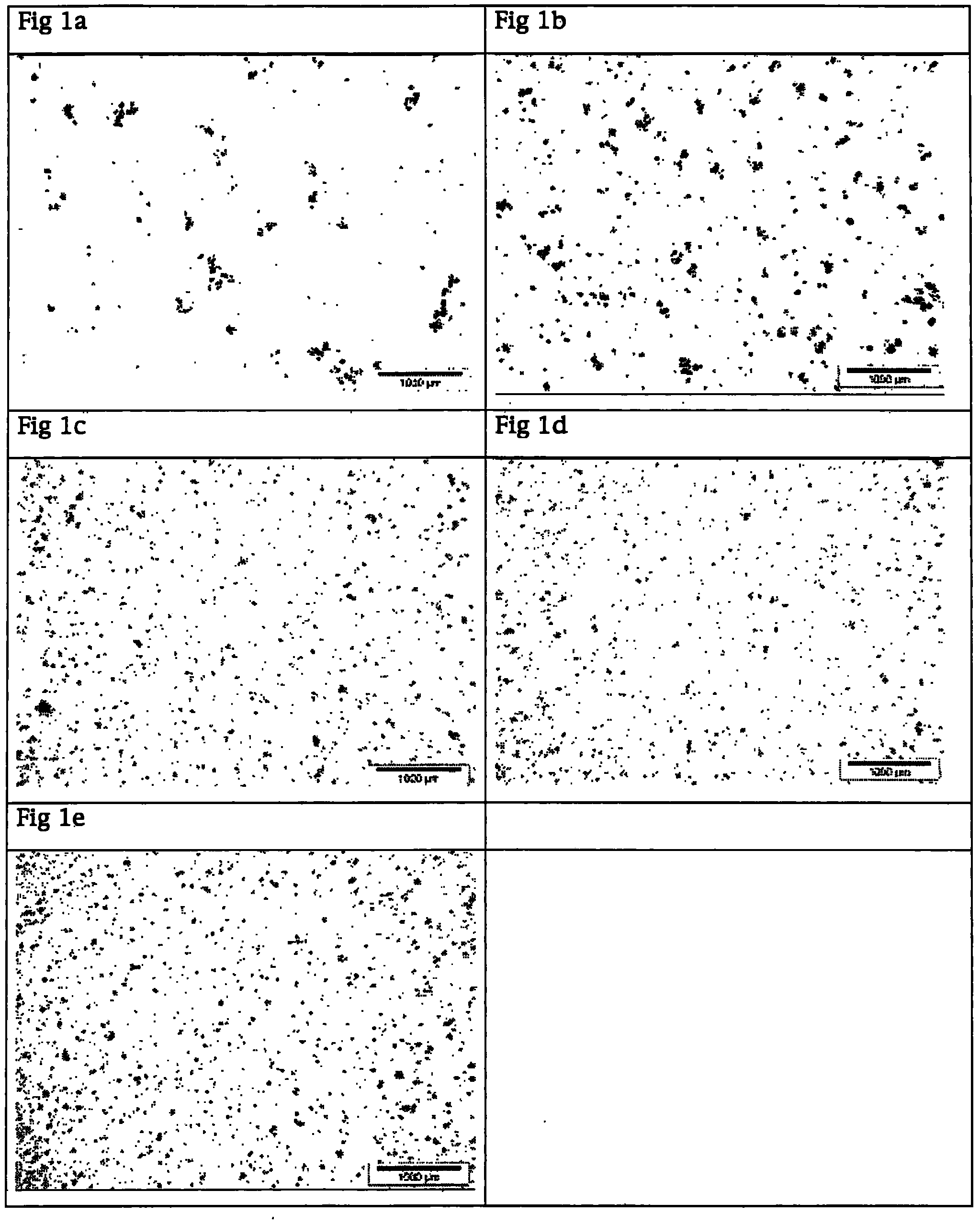

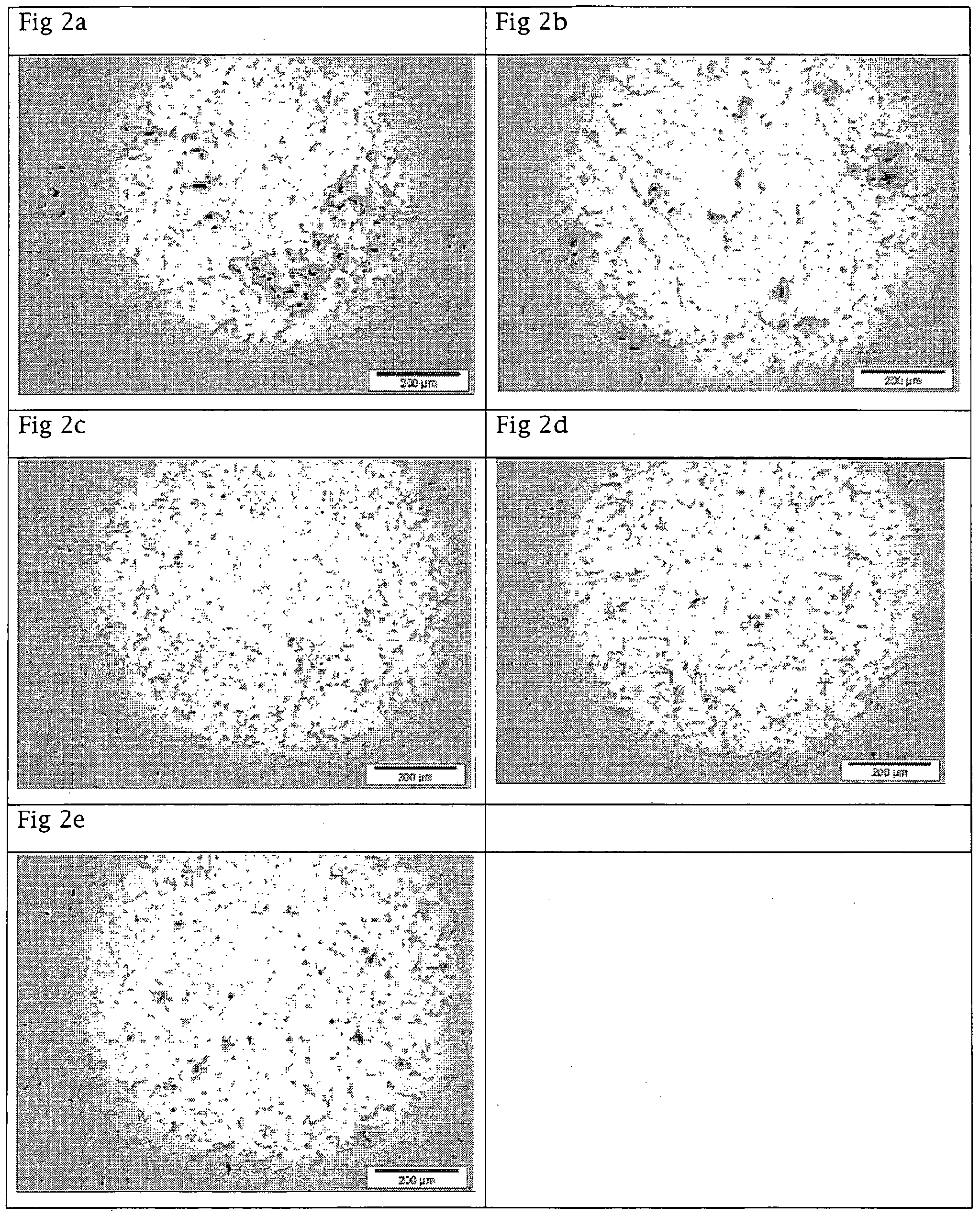

[0084] The microporosity at a rate (representing a rolled slab or extruded billet) was characterized by optical microscopy on a sample taken in the shape of a solidified bloc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com