Outdoor high-voltage isolation energy-taking capacitor structure

A capacitor structure and high-voltage capacitor technology, which is applied in the electrical field, can solve problems such as hidden accidents and cracks, and achieve the effects of improved creepage distance, long service life and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

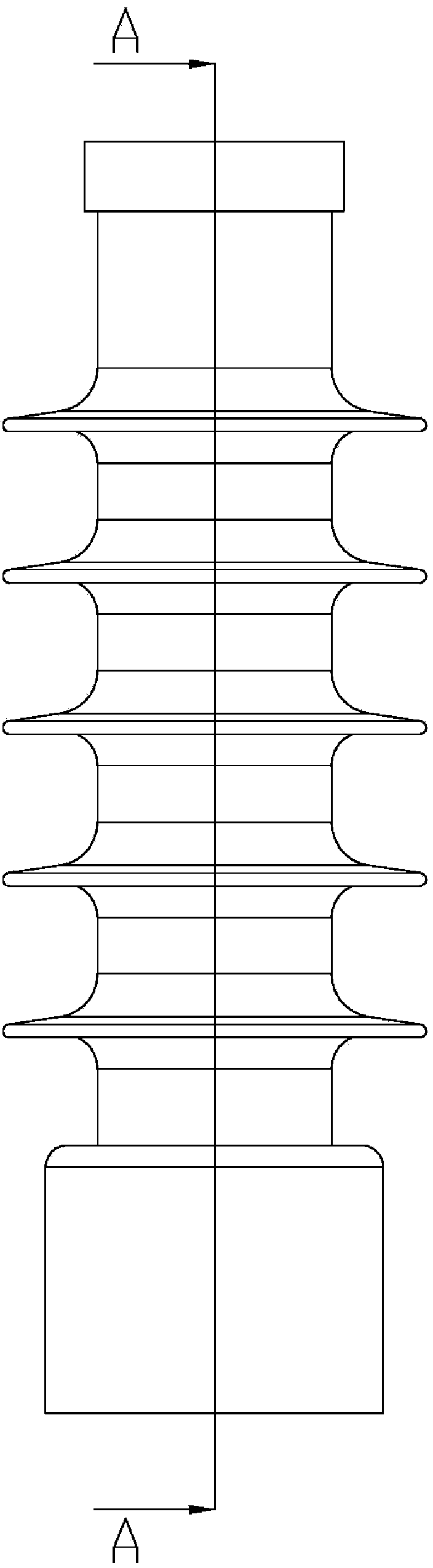

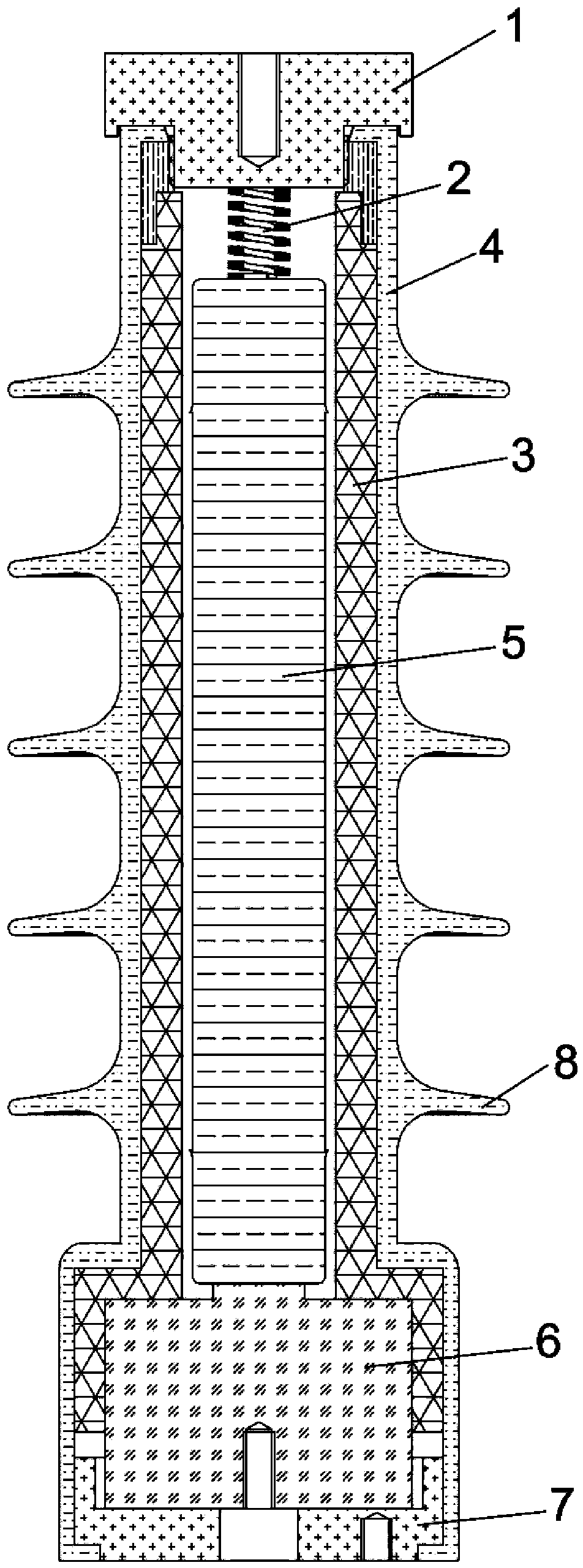

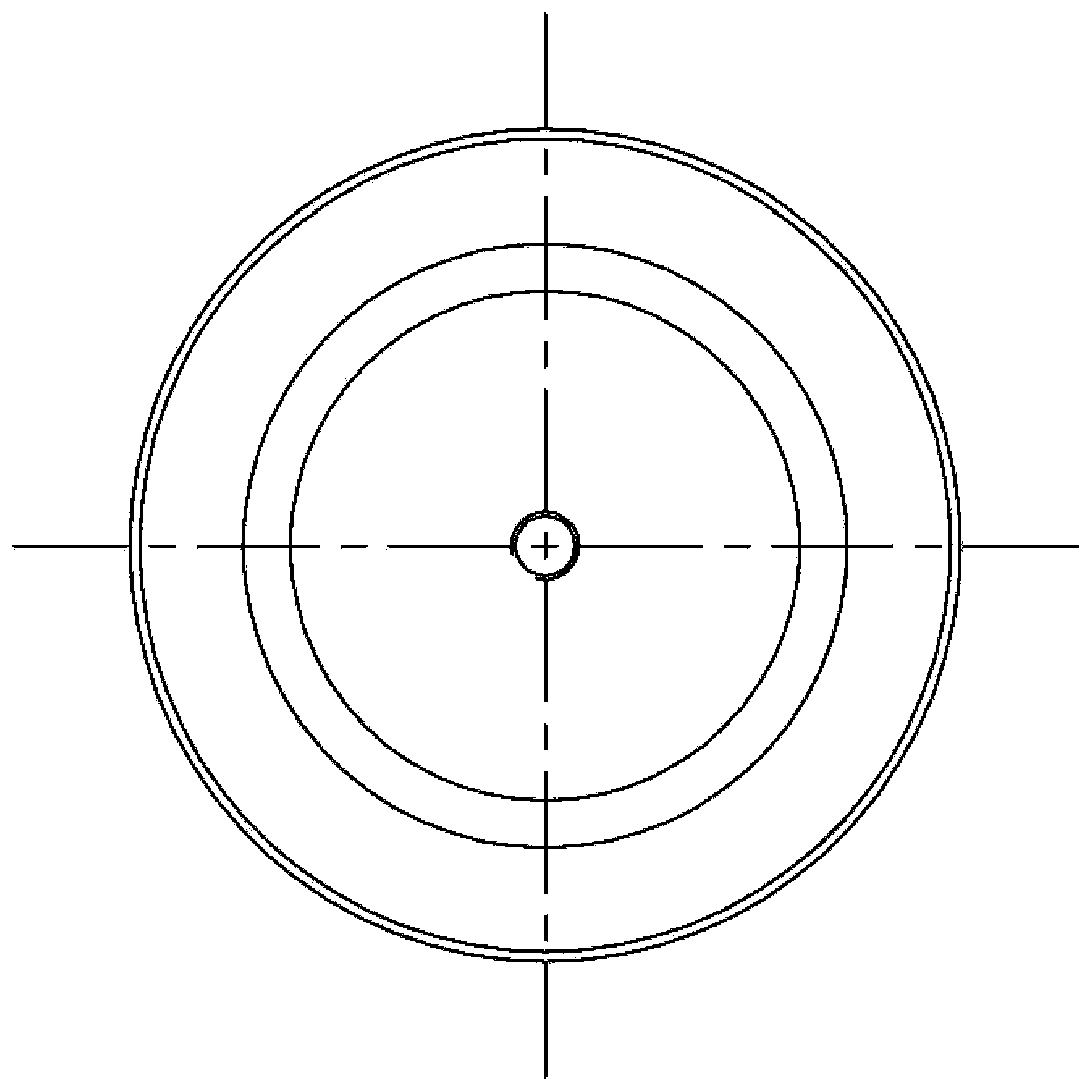

[0017] like figure 1 , figure 2 and image 3 As shown, a kind of outdoor high-voltage isolation energy-taking capacitor structure of the present invention comprises an insulating tube 3, a high-voltage fuse 5 and a high-voltage capacitor 6, wherein, the two ends of the insulating tube 3 are respectively covered by a short-diameter cover plate 1 and A long-diameter cover plate 7 is sealed, and a high-voltage fuse 5 and a high-voltage capacitor 6 are arranged in the insulating tube 3. The high-voltage fuse 5 and the high-voltage capacitor 6 are arranged from the short-diameter cover plate 1 to the long-diameter cover plate 7, and the high-voltage fuse 5 A spring 2 is arranged between the short-diameter cover plate 1, an insulating sheath 4 is set on the outer wall of the insulating tube 3, and more than one umbrella-shaped skirt structure 8 is arranged on the insulating sheath 4, and the umbrella-shaped skirt structure 8 They are arranged at intervals along the axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com