Method for regulating and controlling bioactivity of lysozyme based on induced crystallization effect of ionic liquid

An ionic liquid and induced crystallization technology, applied in biochemical equipment and methods, enzymes, enzymes, etc., can solve the problems that high-purity lysozyme cannot meet the market demand, the manufacturing and production technology of lysozyme is backward, and the quality is competitive. Reduce the primary nucleation rate, reduce the surface tension and nucleation free energy change, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for regulating the biological activity of lysozyme based on the induced crystallization effect of ionic liquids, comprising the following steps:

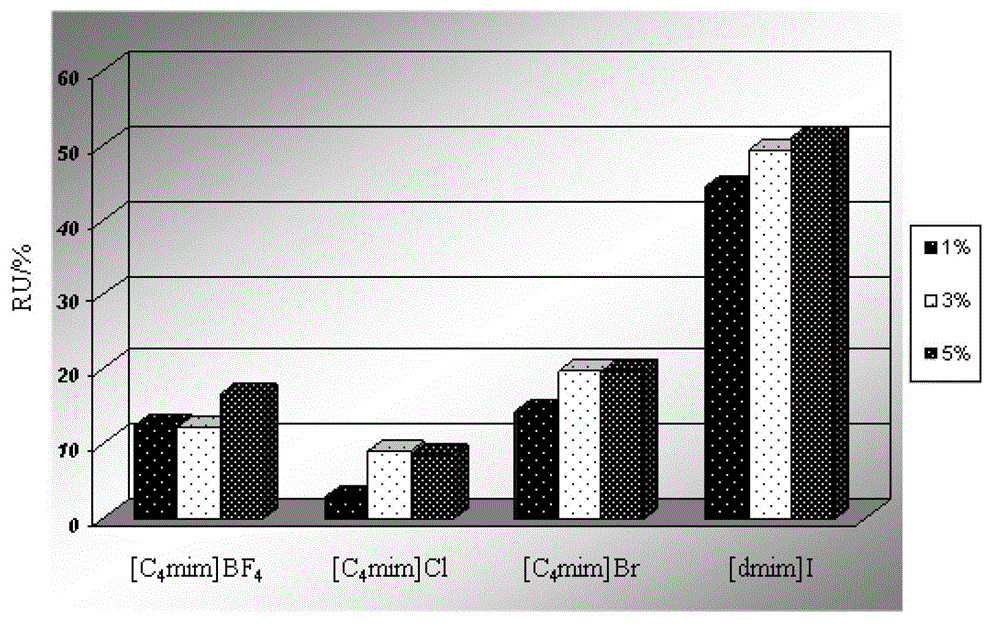

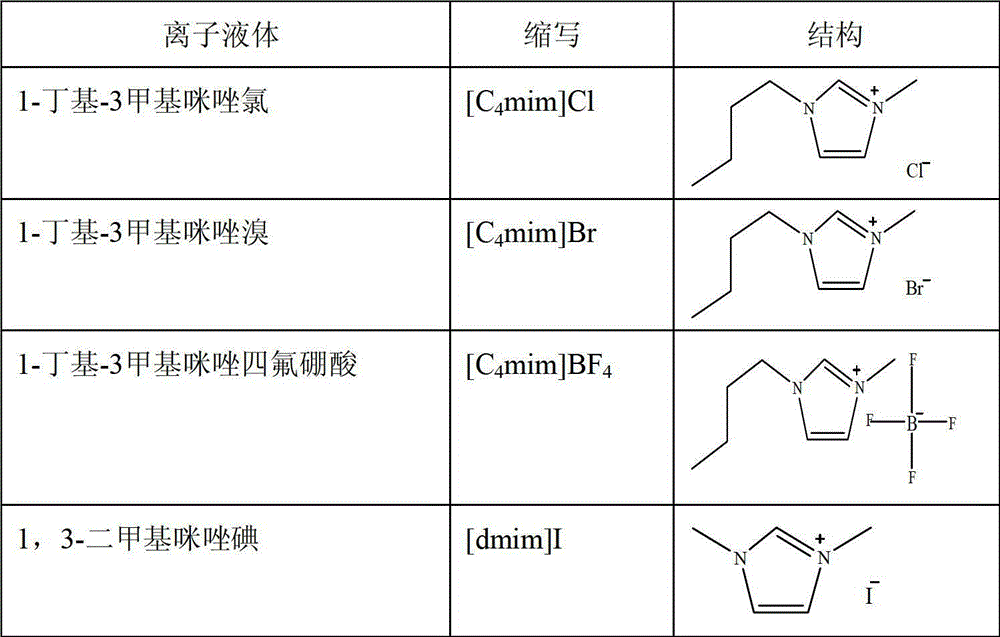

[0024] (1) Add 1-butyl-3 methylimidazolium tetrafluoroboric acid to solution A so that the mass concentration of 1-butyl-3 methylimidazolium tetrafluoroboric acid is 1%, and the pH value of the A solution is = 4, mass concentration is the sodium acetate buffer solution of 3% NaCl;

[0025] (2) Add egg white lysozyme (specific activity 4000U / mg) to the liquid obtained in step (1), so that the supersaturation ratio of the lysozyme at 25°C is 1;

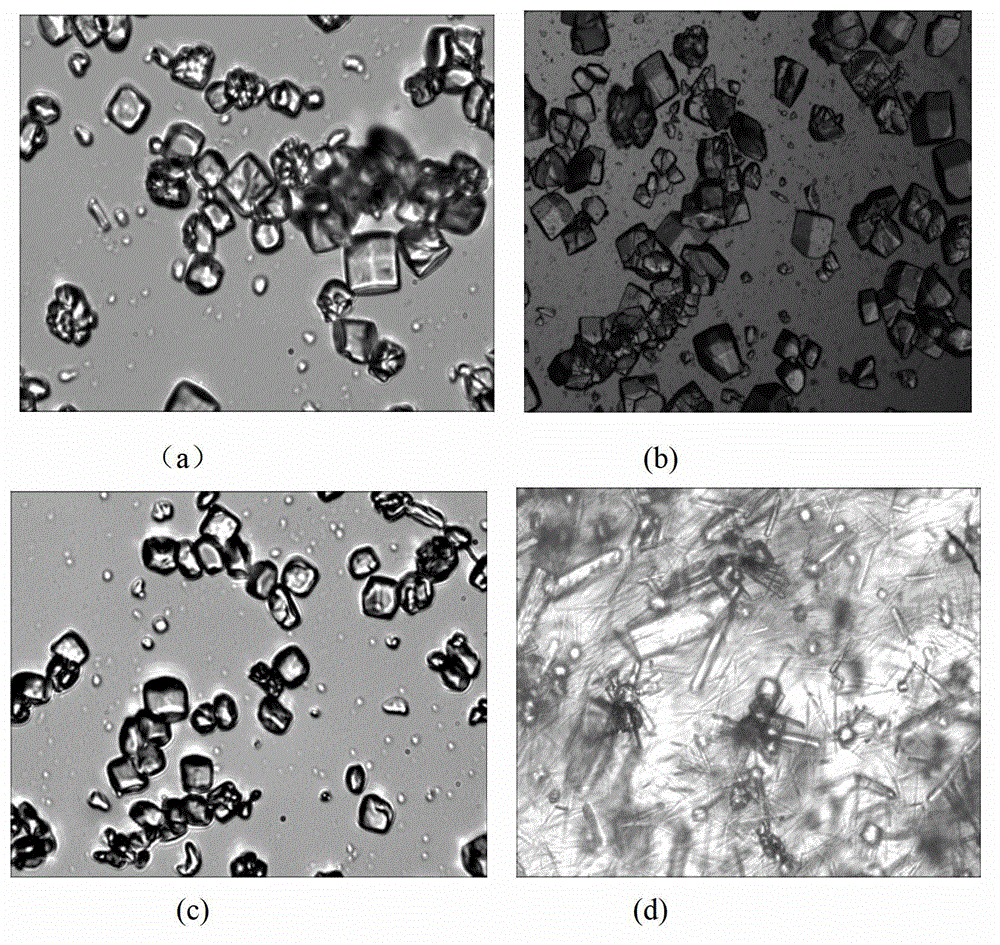

[0026] (3) Under the condition of a stirring speed of 300rpm, cool the liquid obtained in step (2) to crystallization and turbid crystallization for 20 minutes, cool down to 3°C and keep at 3°C for 12 hours to obtain a crystallization liquid, filter the crystallization liquid, and crystallize Dry under vacuum freezing conditions to obtain the lysozyme crystal product, which...

Embodiment 2

[0029] A method for regulating the biological activity of lysozyme based on the induced crystallization effect of ionic liquids, comprising the following steps:

[0030] (1) Add 1-butyl-3 methylimidazole chloride to solution A so that the mass concentration of 1-butyl-3 methylimidazole chloride is 1%, and the A solution is pH=5, mass Concentration is the sodium acetate buffer solution of 4% NaCl;

[0031] (2) Add egg white lysozyme (specific activity 4000U / mg) to the liquid obtained in step (1), so that the supersaturation ratio of the lysozyme at 20°C is 2;

[0032] (3) Under the condition of a stirring speed of 250rpm, cool the liquid obtained in step (2) to crystallization and turbid crystallization for 25 minutes, cool down to 4°C and keep at 4°C for 12 hours to obtain a crystallization liquid, filter the crystallization liquid, and crystallize Dry under vacuum freezing conditions to obtain the lysozyme crystal product, which is stored at a low temperature of 4°C. The ma...

Embodiment 3

[0035] A method for regulating the biological activity of lysozyme based on the induced crystallization effect of ionic liquids, comprising the following steps:

[0036] (1) Add 1-butyl-3 methylimidazolium bromide to solution A so that the mass concentration of 1-butyl-3 methylimidazolium bromide is 1%. Concentration is the sodium acetate buffer solution of 5% NaCl;

[0037] (2) Add egg white lysozyme (specific activity 4000U / mg) to the liquid obtained in step (1), so that the supersaturation ratio of the lysozyme at 25°C is 2.5;

[0038] (3) Under the condition of a stirring speed of 350rpm, cool the liquid obtained in step (2) to crystallization and turbid crystallization for 25 minutes, cool down to 4°C and keep at 4°C for 18 hours to obtain a crystallization liquid, filter the crystallization liquid, and crystallize Dry under vacuum freezing conditions to obtain the lysozyme crystal product, which is stored at a low temperature of 4°C. The main particle size of the obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com