Rotation surface precision machining clamp with adjustable off-axis quantity

A surface of revolution, precision machining technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of cylindrical workpieces having no applicability, limited size, and the off-axis position of the workpiece cannot be adjusted arbitrarily, to achieve The effect of expanding the processing space and solving processing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

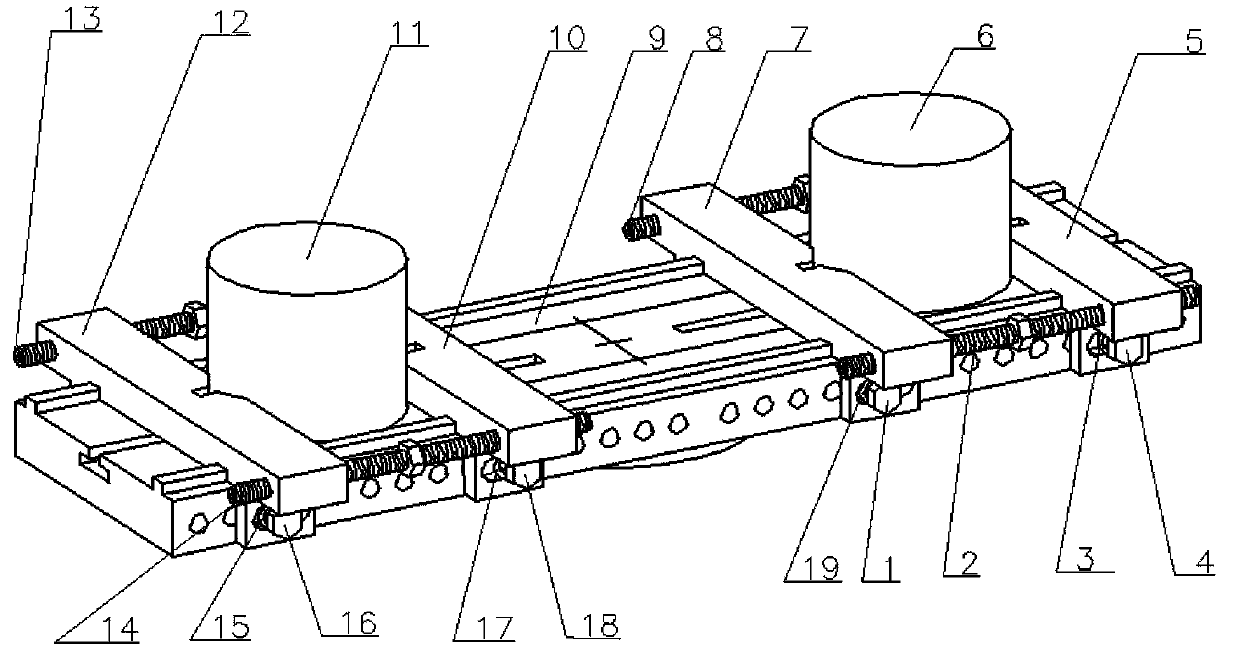

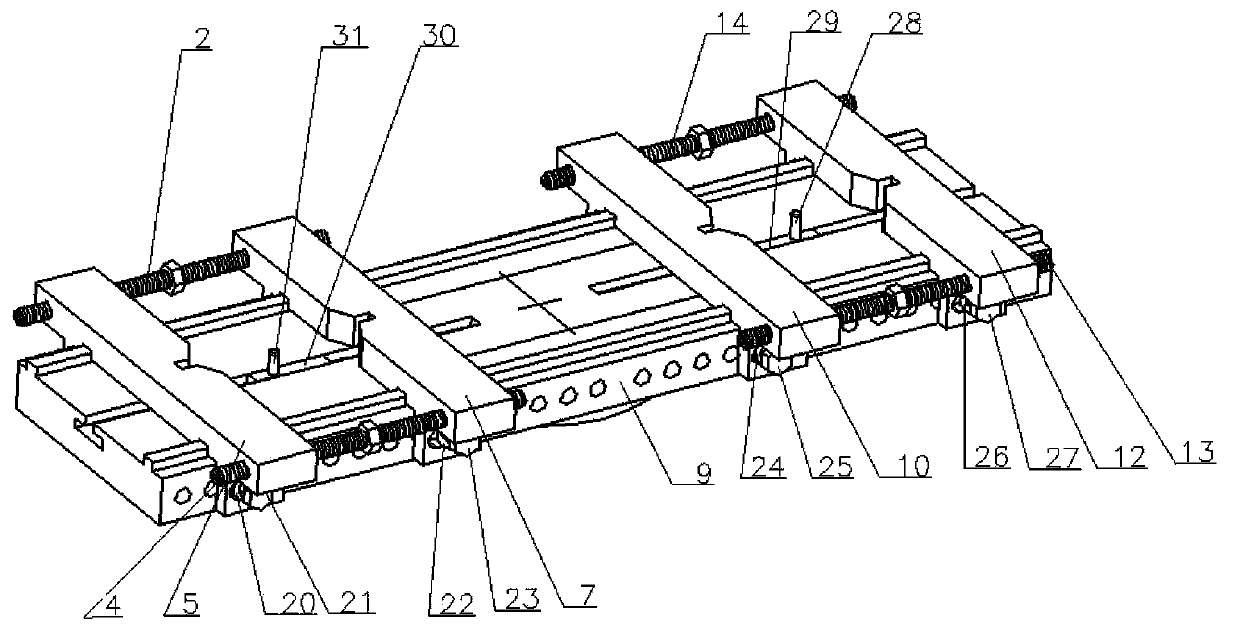

[0028] The overall structure of the program is as follows figure 1 As shown, it includes fixture base, clamping screw Ⅰ1, bolt Ⅰ2, gasket Ⅰ3, clamping screw Ⅱ4, V-shaped block Ⅰ5, cylindrical workpiece Ⅰ6, V-shaped block Ⅱ7, bolt Ⅱ8, V-shaped block Ⅲ10, column Shaped workpiece Ⅱ11, V-shaped block Ⅳ12, bolt Ⅲ13, bolt Ⅳ14, gasket Ⅱ15, clamping screw Ⅲ16, gasket Ⅲ17, clamping screw Ⅳ18, gasket Ⅳ19, gasket Ⅳ20, clamping screw Ⅴ21, gasket Ⅵ22, Clamping screw Ⅵ23, washer Ⅶ24, clamping screw Ⅶ25, washer Ⅷ26, clamping screw Ⅷ27, positioning pin Ⅰ28, T-slider Ⅰ29, T-slider Ⅱ30 and locating pin Ⅱ31.

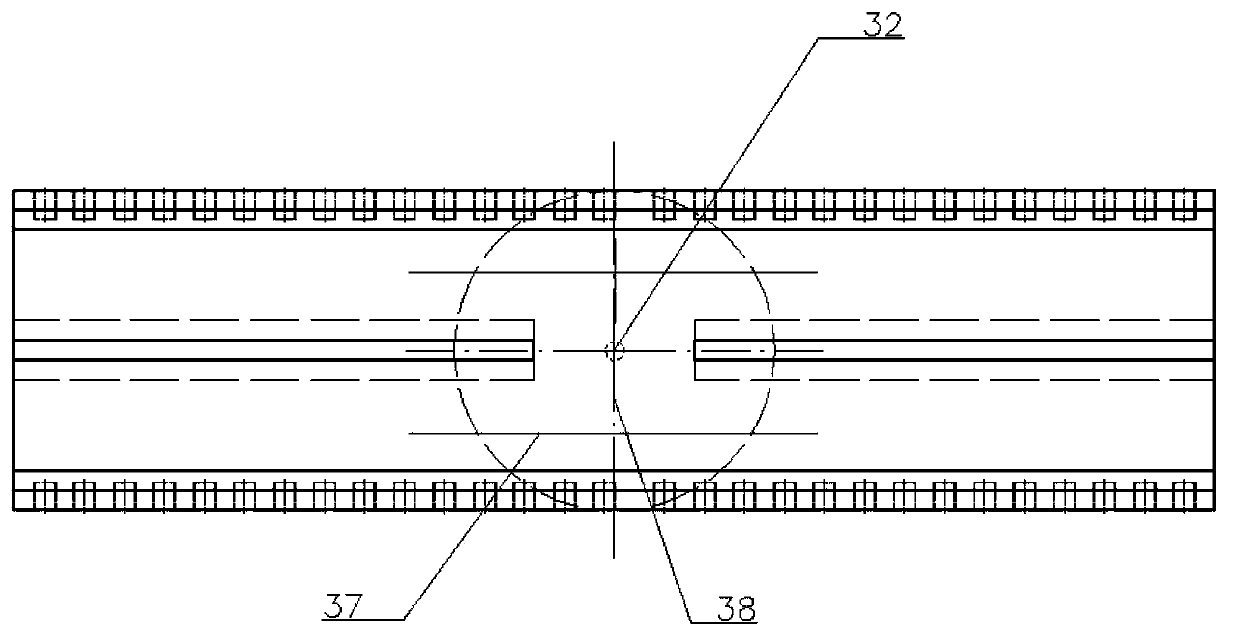

[0029]Among them, the fixture base includes a fixture base plate 9, which is provided with positioning holes 32, guide rails 33, T-shaped slots 34, equidistant threaded hole arrays 35, and adsorption discs 36, wherein V-shaped blocks I5 and V-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com