Preparation method of amorphous C-N thin film electrocatalyst

An electrocatalyst, C-N technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as difficulty in judging catalytic activity, complex operation process, inactivity, etc., to eliminate catalytic activity. effect, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

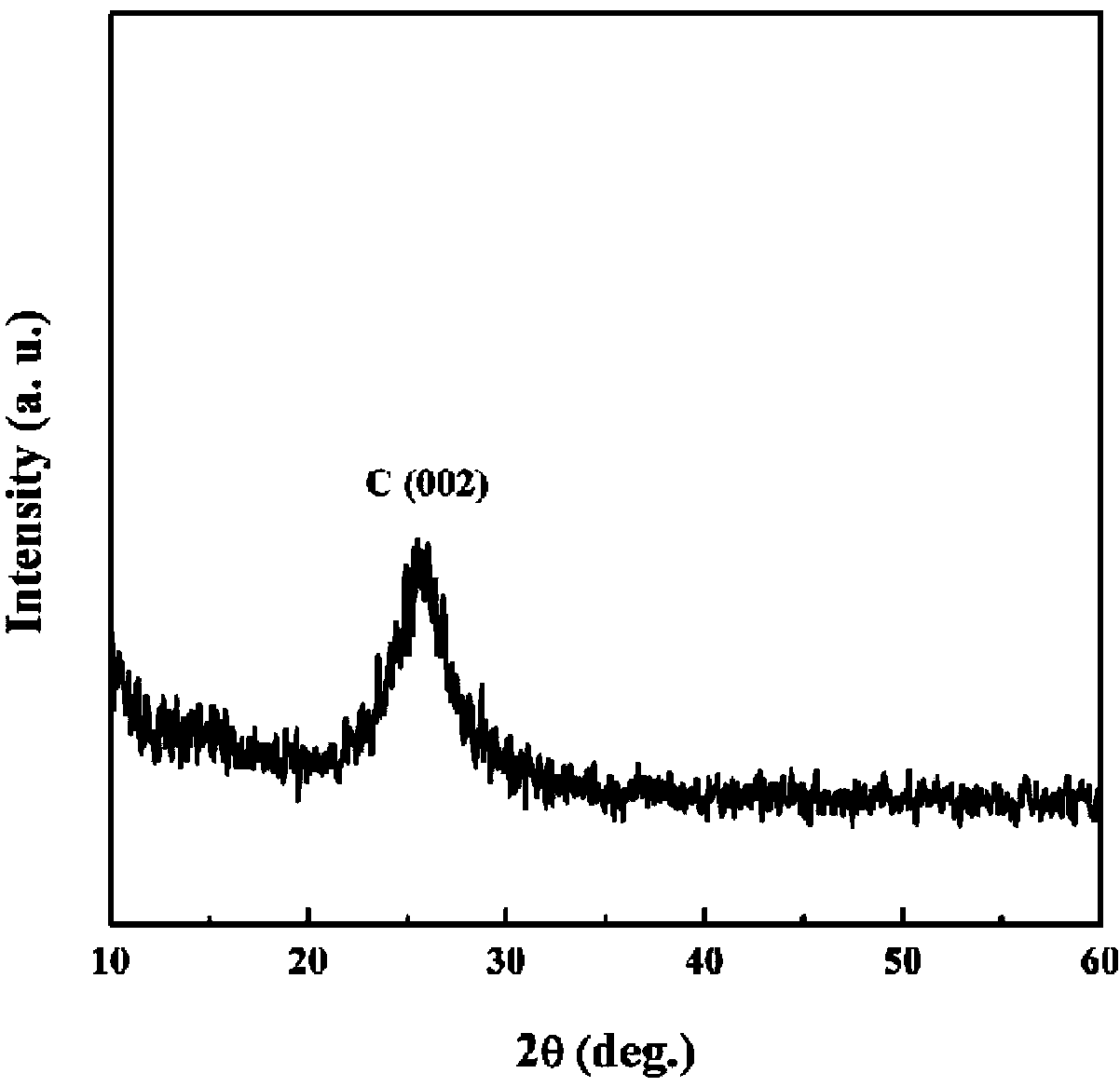

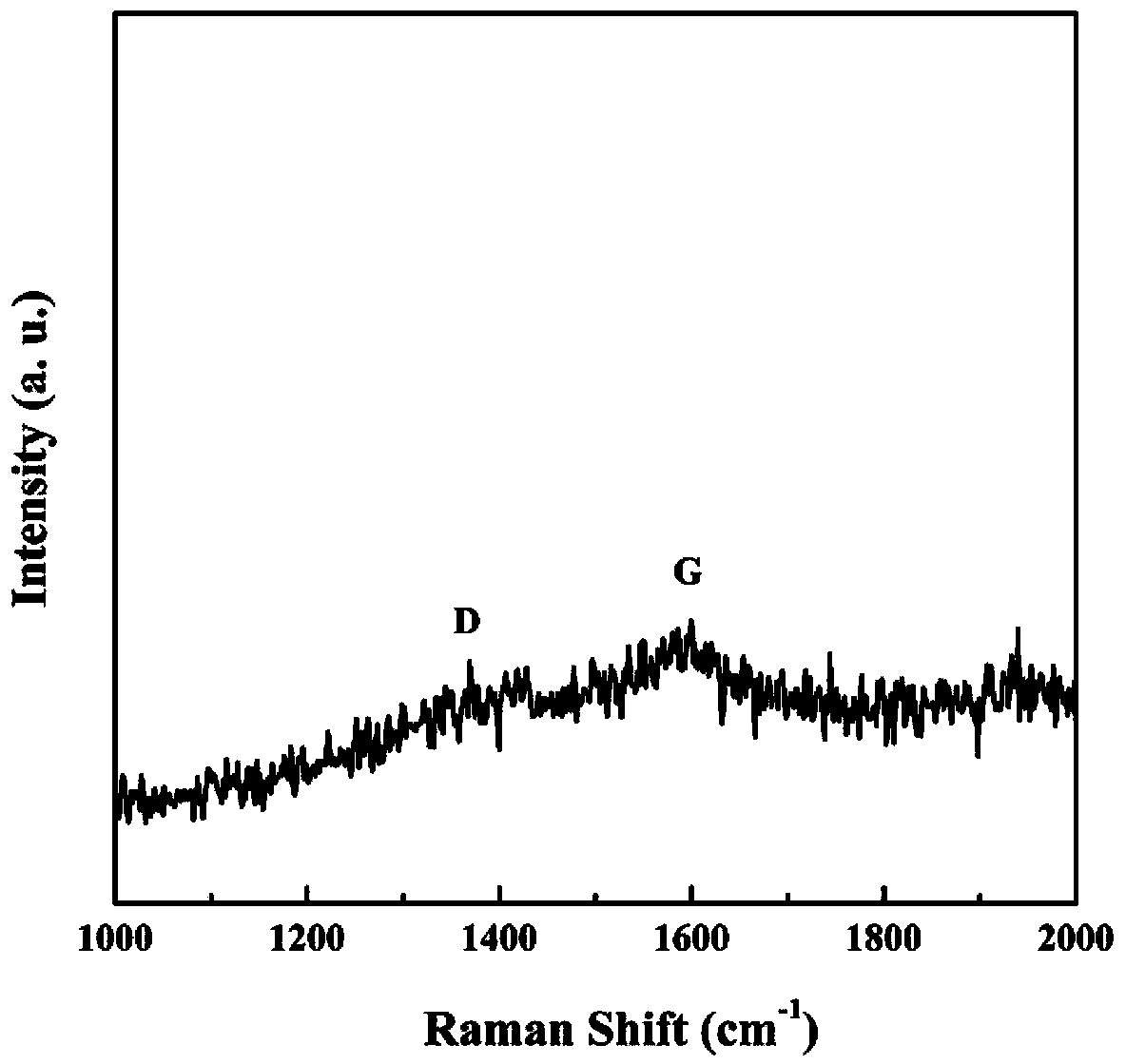

[0028] The preparation of the C-N thin film in the present invention adopts the radio frequency magnetron sputtering deposition technology and uses polycrystalline titanium as the substrate. It is mainly divided into the following steps:

[0029] 1) The system is evacuated, and the sputtering gas and reaction gas are introduced, and wait for a period of time to make the gas mix evenly.

[0030] 2) A reasonable ratio of carbon source gas, nitrogen source gas, and sputtering gas, that is, CH 4 / N 2 / Ar=25 / 15 / 20, the unit is sccm, adjust the background pressure, set the RF power, sputtering time and substrate bias, the reaction raw materials are fully ionized, decomposed, and converted into active groups, in polycrystalline titanium The C-N film is finally deposited on the substrate.

[0031] 3) Cool down to below 100°C with protective gas.

[0032] In the present invention, a high-vacuum heat treatment furnace is used to heat-treat the film to obtain the final C-N catalyst. ...

Embodiment 1

[0043] 1) Using radio frequency magnetron sputtering equipment, deposit C-N thin films on polycrystalline titanium sheets, using high-purity carbon targets, when the background pressure reaches 1×10 -4 Pa, sequentially into CH 4 , N 2 and Ar gas, and adjust the gas flow to 25, 15, and 20 sccm respectively, and wait for a period of time to make the gas mix evenly.

[0044] 2) Adjust the reaction pressure to 0.5Pa, and after the pressure is stable, adjust the substrate bias to -150V.

[0045] 3) Turn on the RF power supply, the RF power is 150W, start sputtering, and the sputtering time is 40min.

[0046] 4) After the sputtering is over, take out the sample and wait for the next step.

[0047] 5) Put the sample into a high vacuum heat treatment furnace, when the background pressure reaches 1×10 -4 At Pa, the protective gas Ar is introduced, the heating time is 2h, the heat treatment temperature is 700°C, and the holding time is 5min.

[0048] 6) After the heat treatment, co...

Embodiment 2

[0051] Change the substrate bias value in Step 2) of Example 1 from the floating voltage to -50V, and the rest of the steps are the same as in Example 1, and the current density can reach 3.22mA cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com