Super-lattice waveguide semiconductor laser structure

A superlattice and laser technology, applied in the structure of optical waveguide semiconductors, can solve the problems of electron and hole electrical confinement imbalance, optical field distribution optimization, etc., to optimize the effective refractive index, improve electrical characteristics, increase The effect of output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0029] Combine below figure 1 The structural details of a superlattice waveguide semiconductor laser according to a specific embodiment of the present invention will be described in detail.

[0030] refer to figure 1 , the present invention is a superlattice waveguide semiconductor laser structure, comprising:

[0031] A substrate 10 is an N-type GaAs material of (100) plane, and the substrate 10 is used to epitaxially grow each layer of material of the laser thereon;

[0032] A buffer layer 11, made of N-GaAs material, the buffer layer 11 is fabricated on the substrate 10, and is mainly used to adjust the lattice fit;

[0033] An N-type lower confinement layer 12, which is N-In 1-x Ga x As y P 1-y material, the N-type lower confinement layer 12 is fabricated on the buffer layer 11;

[0034] An N-type lower waveguide layer 13, which is N-In 1-x Ga x As y P 1-y material, the lower waveguide layer 13 is made on the lower confinement layer 12;

[0035] A quantum well ...

Embodiment

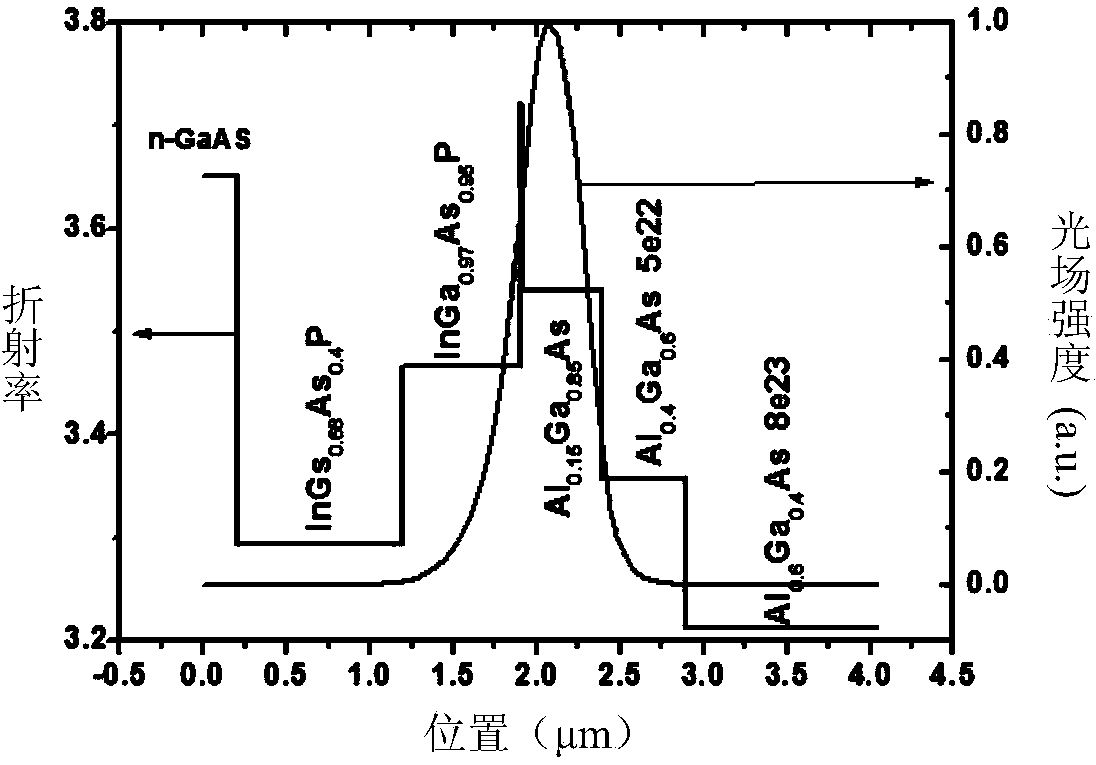

[0044] This embodiment adopts figure 1 The structure shown shows the laser light field distribution under the modulation of the superlattice waveguide. The substrate of the structure is N-type GaAs material, and the material and thickness of each layer of the structure from bottom to top are as follows:

[0045] The substrate material and thickness are GaAs, 0.2 μm; the lower confinement layer material and thickness are In 0.32 Ga 0.68 As 0.4 P 0.6 ,1μm; the material and thickness of the lower waveguide layer are In 0.03 Ga 0.97 As 0.95 P 0.05, 0.7μm; quantum well layer material and thickness are In 0.3 Ga 0.7 As, 9nm; the material and thickness of the upper superlattice waveguide with low Al components are Al 0.15 Ga 0.85 As, 8nm; the material and thickness of the upper superlattice waveguide with high Al composition are Al 0.4 Ga 0.6 As, 10nm; the material and thickness of the upper waveguide layer are Al 0.4 Ga 0.6 As, 0.8μm; the material and thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com