Two-sided passivation efficient heterojunction battery and manufacturing method thereof

A heterojunction cell and double-sided passivation technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of complex manufacturing process, high equipment requirements, and difficulty in mass production, so as to improve the internal reflection of the back , improve short-circuit current, increase the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

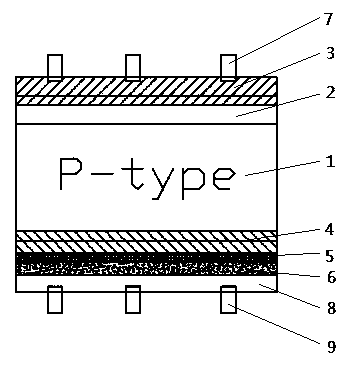

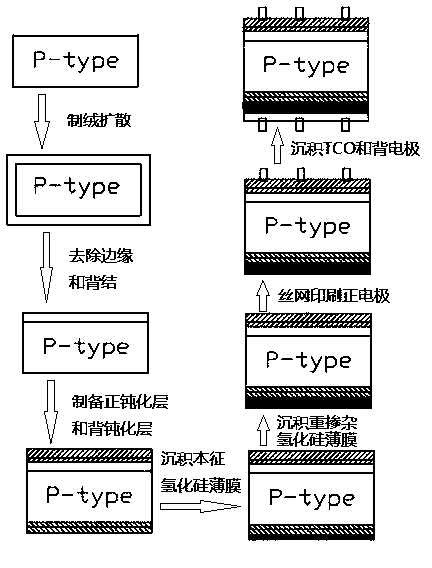

[0014] See figure 1 The double-sided passivated high-efficiency heterojunction cell includes a crystalline silicon base layer 1, an amorphous n layer 2, a positive passivation layer 3 and a positive electrode 7 are arranged on the front surface of the crystalline silicon base layer 1 in sequence, and the amorphous n layer 2 and the crystalline silicon base layer 1 A solar PN junction is formed, and the rear surface of the crystalline silicon base layer 1 is provided with a back passivation layer 4 , an intrinsic hydrogenated silicon film 5 , a heavily doped hydrogenated silicon film 6 , a transparent conductive film TCO8 and a back electrode 9 . The positive passivation layer 3 and the back passivation layer 4 can be a single-layer passivation film structure or a double-layer passivation film structure. For a single-layer passivati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com