A micro-power electronic product integrating organic photovoltaic cells

A technology of organic photovoltaic cells and electronic products, applied in photovoltaic power generation, battery circuit devices, current collectors, etc., can solve problems such as the decline of photoelectric conversion efficiency, and achieve the effect of excellent photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

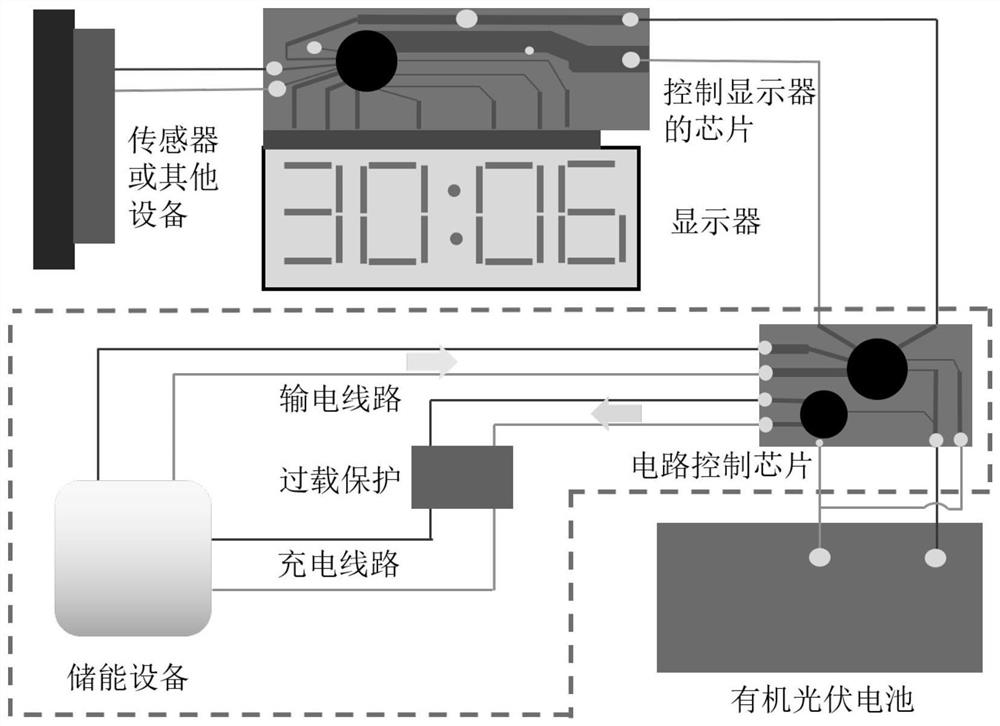

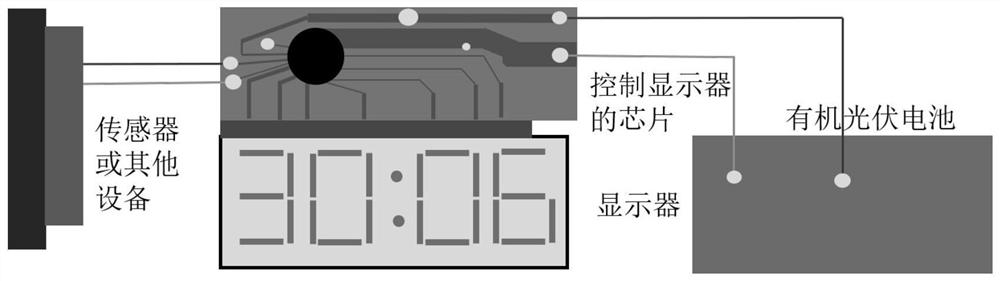

[0051] Embodiment 1, based on organic photovoltaic device

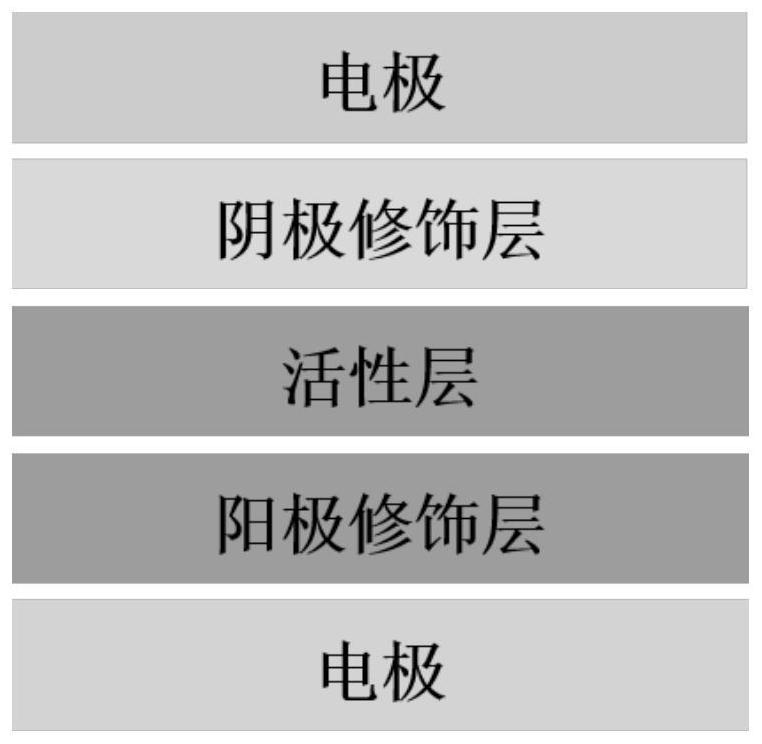

[0052] This example uses the PBDB-TF / IO-4Cl (mass ratio 1:1.5) system to prepare organic photovoltaic cells according to the general processing technology (the device structure is ITO / PEDOT:PSS / PBDB-TF:IO-4Cl / PFN-Br / Al), wherein, the structural formula of PBDB-TF (n is 20 in the formula) and IO-4Cl is as Figure 7 shown.

[0053] device is filled with N 2 The solar simulator was used in the glove box to test, and the current density-voltage curve of the organic photovoltaic cell is shown in Figure 8 . The photoelectric conversion efficiency is 9.64%, the corresponding voltage is 1.24V, and the current is 11.6mA / cm 2 , the fill factor is 0.670. filled with N 2 A 2700K color temperature LED lamp was used in the glove box for testing. Under 500lux, the current density-voltage curve after the test is shown in Figure 9 . Among them, the open circuit voltage is 1.05V, and the short circuit current is 46.2uA / cm ...

Embodiment 2

[0054] Embodiment 2, based on organic photovoltaic devices

[0055] This example uses the PBDB-TF / ITCC (mass ratio 1:1) system to prepare organic photovoltaic cells according to the general processing technology, wherein, the structural formula of PBDB-TF (where n is 20) and ITCC is as follows Figure 7 shown.

[0056] device is filled with N 2 The solar simulator was used in the glove box to test, and the current density-voltage curve of the organic photovoltaic cell is shown in Figure 11 . The photoelectric conversion efficiency is 10.3%, the corresponding voltage is 1.10V, and the current is 14.5mA / cm 2 , the fill factor is 0.643. filled with N 2 A 2700K color temperature LED lamp was used in the glove box for testing. Under 500lux, the current density-voltage curve after the test is shown in Figure 12 . Among them, the open circuit voltage is 0.948V, and the short circuit current is 47.8uA / cm 2 , the fill factor is 0.706, and the photoelectric conversion efficie...

Embodiment 3

[0057] Embodiment 3, based on organic photovoltaic device

[0058] This example uses the PBDB-TF / IT-4F (mass ratio 1:1) system to prepare organic photovoltaic cells according to the general processing technology, wherein, the structural formula of PBDB-TF (where n is 20) and IT-4F is as follows Figure 7 shown.

[0059] device is filled with N 2 The solar simulator was used in the glove box to test, and the current density-voltage curve of the organic photovoltaic cell is shown in Figure 13 . The photoelectric conversion efficiency is 12.2%, the corresponding voltage is 0.872V, and the current is 20.4mA / cm 2 , the fill factor is 0.687. filled with N 2 A 2700K color temperature LED lamp was used in the glove box for testing. Under 500lux, the current density-voltage curve after the test is shown in Figure 14 . Among them, the open circuit voltage is 0.692V, and the short circuit current is 56.6uA / cm 2 , the fill factor is 0.756, and the photoelectric conversion effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com