Numerical control product line of agricultural mini-tiller walking box

A technology of walking box and micro-tiller, applied in metal processing machinery parts, clamping, supporting and other directions, can solve the problems of outdated production means, large amount of old line equipment, and inability to improve benefits, etc., to improve indexing and positioning. Accuracy, strong industrial vitality, and the effect of equipment in place at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

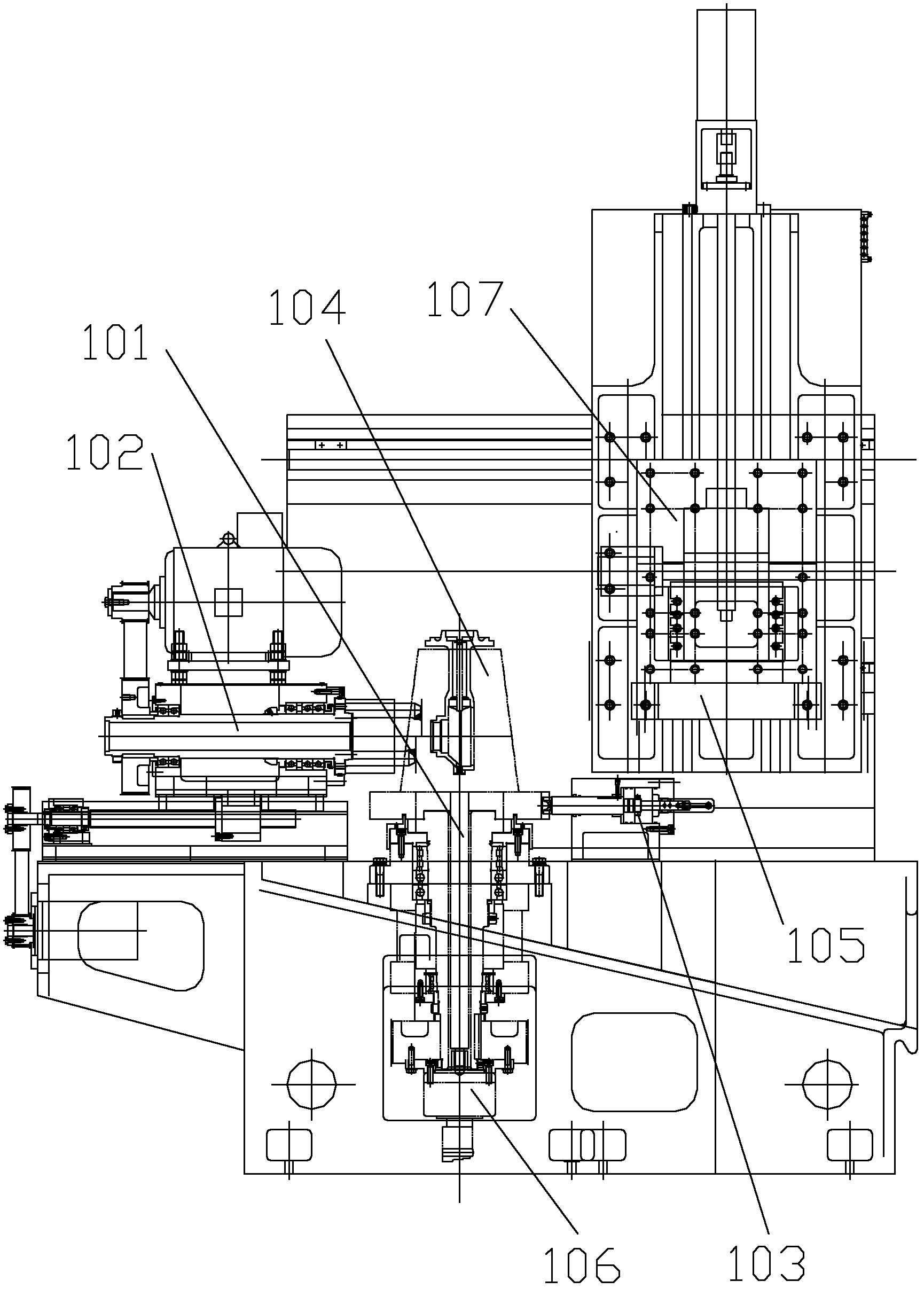

[0043] A kind of CNC production line of walking box of agricultural micro tillage machine, see attached Figure 1-7 , which is composed of the following two parts: a three-coordinate vertical double-spindle CNC lathe, and a rotary table-type combined machine tool; the two parts are arranged in sequence to jointly form the CNC production line for the walking box of the agricultural tiller;

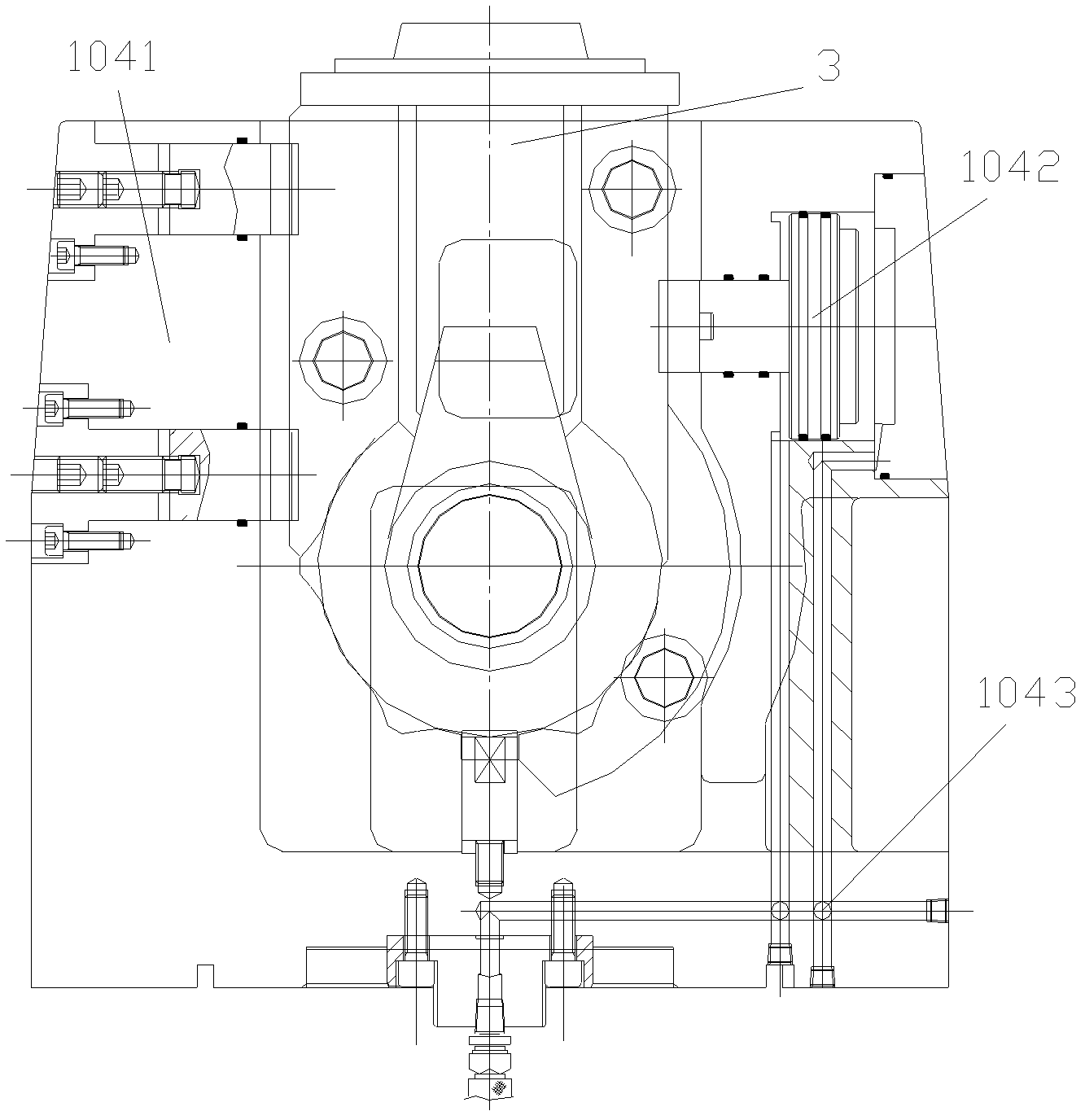

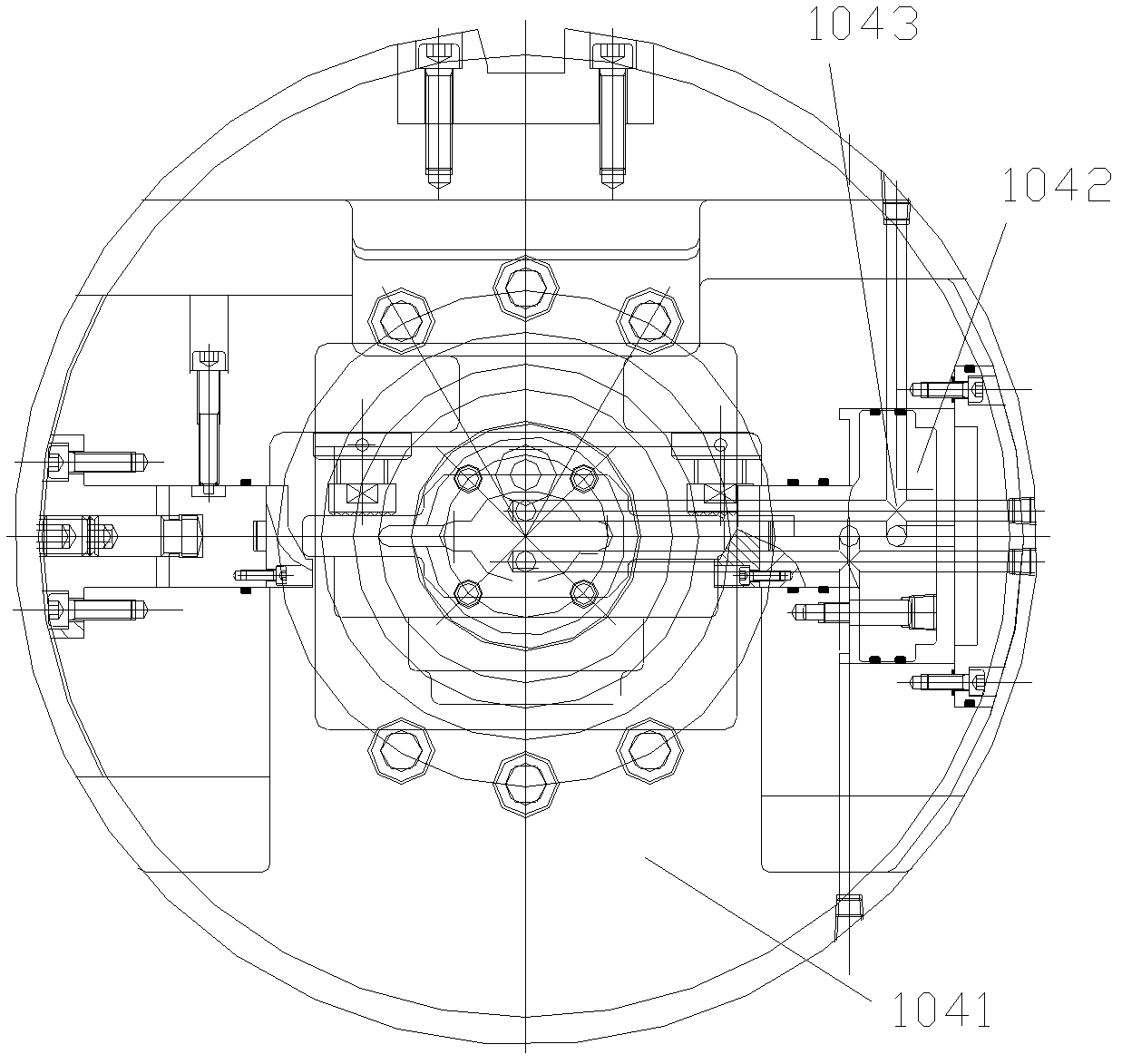

[0044] ① The three-coordinate vertical dual-spindle CNC lathe includes the following components: first spindle 101, second spindle 102, spindle locking device 103, special hydraulic fixture 104, turret tool holder 105, and oil distribution system 106 , two-coordinate linkage axis 107, machine body; wherein:

[0045] All other parts are directly or indirectly arranged and installed on the machine body;

[0046] The first main shaft 101 and the second main shaft 102 are arranged perpendicular to each other; the first main shaft 101 is arranged vertically on the ground, and the special hydrau...

Embodiment 2

[0072] A kind of numerical control production system of agricultural tillage machine, refer to the attached Figure 1~5 , which consists of the following two parts: a three-coordinate vertical double-spindle CNC lathe, and a rotary combined machine tool;

[0073]The three-coordinate vertical dual-spindle CNC lathe includes the following components: a first spindle 101 and a second spindle 102 arranged perpendicular to each other, a spindle locking device 103, a special hydraulic fixture 104, a turret tool holder 105, an oil distribution System 106, two-coordinate linkage axis 107, machine tool body, three-coordinate CNC servo axis (X+Y+Z); wherein: other parts are directly or indirectly arranged and installed on the machine tool body; the first spindle 101 is arranged vertically on the ground , the special hydraulic clamp 104 used for clamping the workpiece and performing rotating processing is installed on the first main shaft 101, and the special hydraulic clamp 104 can real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com