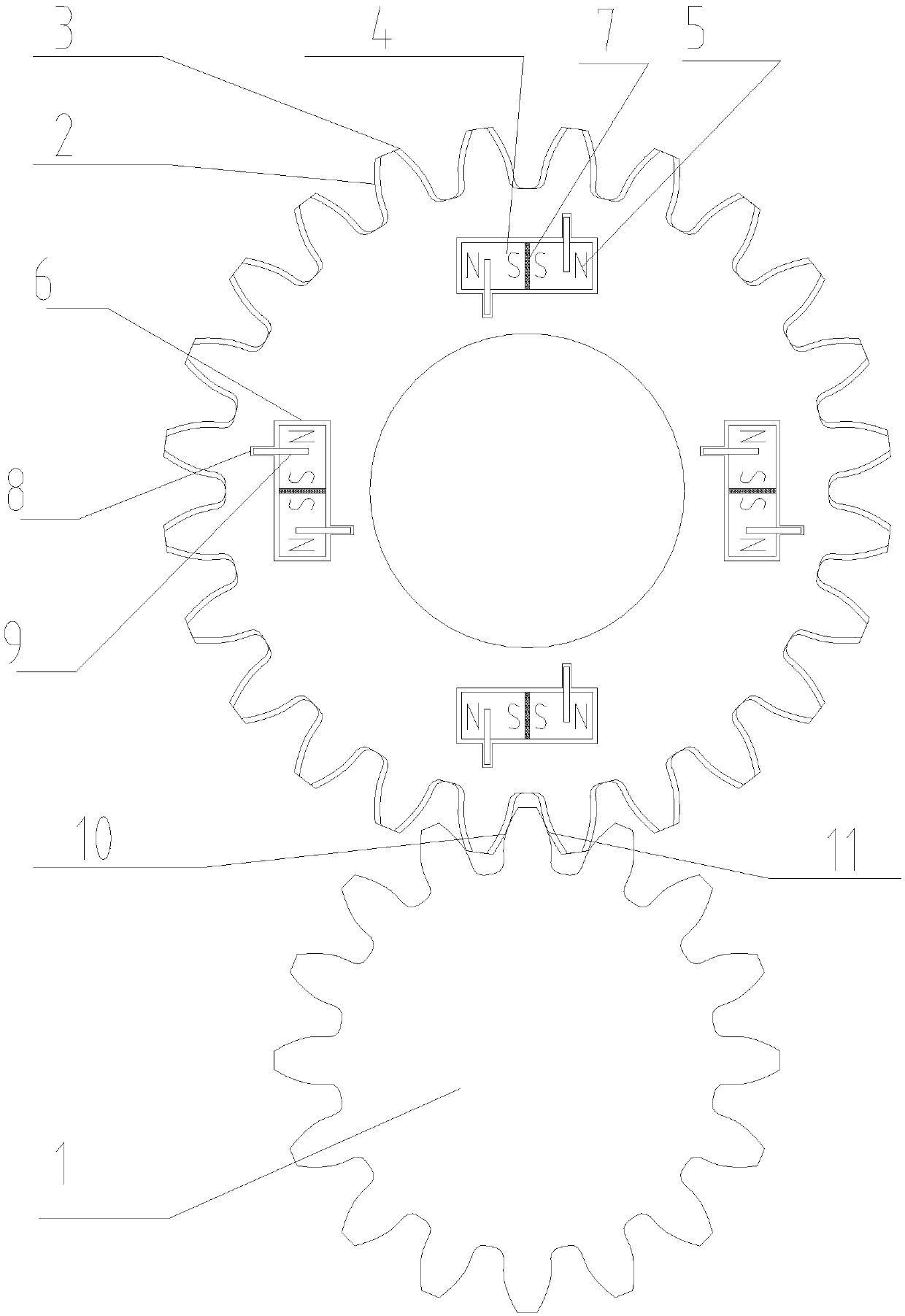

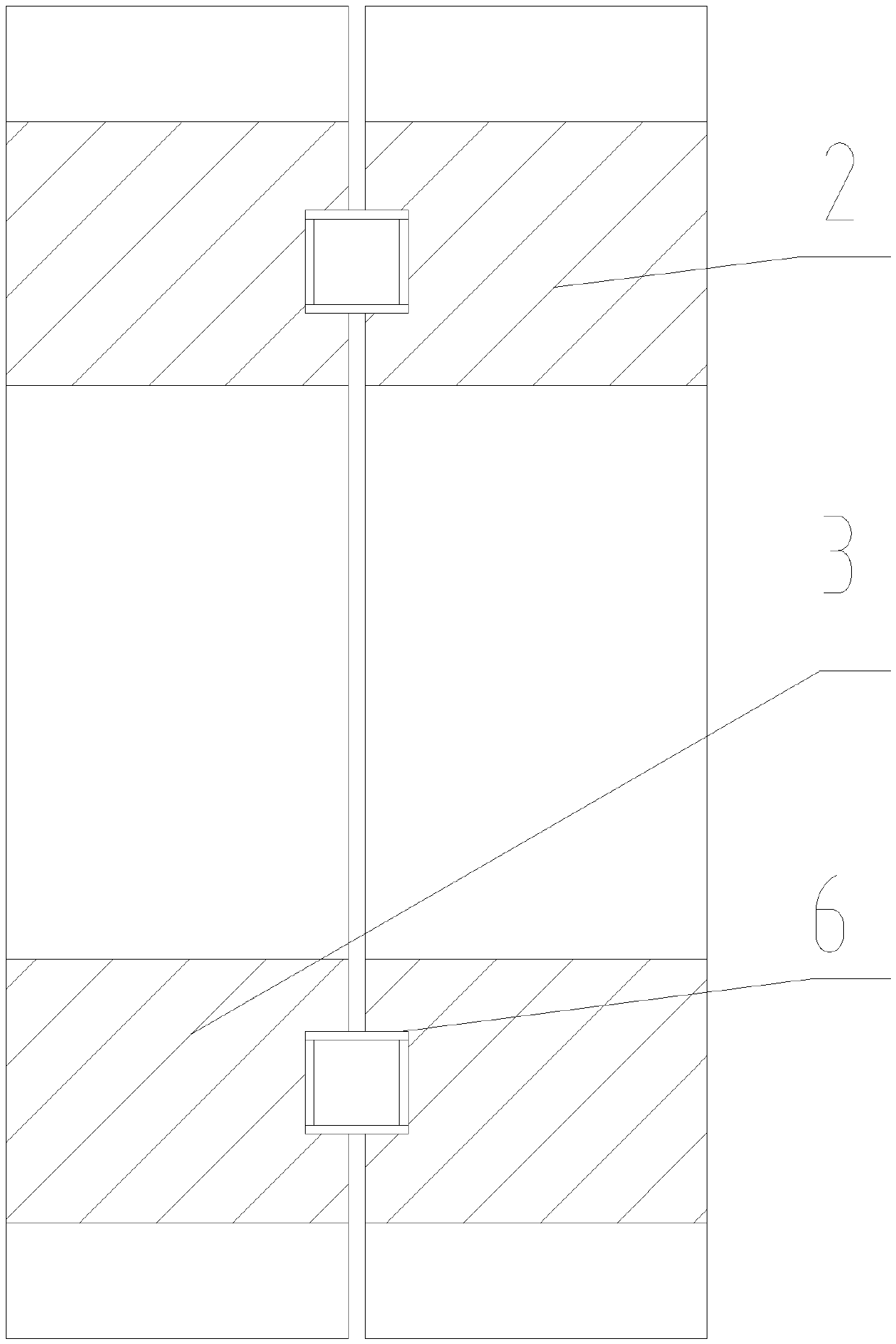

Magnetic gear transmission pair

A gear transmission and gear technology, applied in belts/chains/gears, transmission parts, components with teeth, etc., can solve the problems of affecting accuracy, impact, gear friction and wear, etc., to extend service life, reduce friction, The effect of eliminating gear backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: 42-52 parts of mineral oil, 5-10 parts of stearic acid, 5-8 parts of superfine silica powder, 1-5 parts of silane coupling agent, 1-3 parts of nano filler, 1-3 parts of antioxidant, 1-3 parts of surfactant, 1-3 parts of defoamer, 25-30 parts of water.

[0033] The anti-overheating wear agent can resist friction for 3 hours, and the temperature is controlled at 280-300°C to reduce friction and wear caused by high temperature. The average wear speed is 50% lower than that of smearing.

Embodiment 2

[0034] Embodiment 2: 42-52 parts of mineral oil, 5-10 parts of stearic acid, 5-8 parts of superfine silica powder, 1-5 parts of silane coupling agent, 1-3 parts of nano filler, 1-3 parts of antioxidant, 1-3 parts of surfactant, 1-3 parts of defoamer, 25-30 parts of water.

[0035] The anti-overheating wear agent can resist friction for 4 hours, and the temperature is controlled at 260-290°C to reduce friction and wear caused by high temperature. The average wear speed is 60% lower than that of smearing.

[0036] Ultrafine silica powder over 600 mesh.

[0037] The preparation method of the anti-overheating wear agent is as follows: put mineral oil, stearic acid, ultrafine silicon micropowder, and water in a reaction kettle, add a surfactant dropwise, at a temperature of 40.6-70.0°C and a pressure of 0.70-0.95MPa , react until the pressure begins to drop, add antioxidant, react until the pressure is 0.4-0.56MPa, stop adding the silane coupling agent dropwise;

[0038] Under th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com