Method for improving visual whiteness of blanching chemimechanical pulp and blanching chemimechanical pulp

A chemical-mechanical and whiteness bleaching technology, which is applied in chemical/chemical-mechanical pulp, pulp raw material addition process, textiles and papermaking, etc., can solve the problems that the apparent whiteness of pulp does not meet the requirements, and the cost of papermaking increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

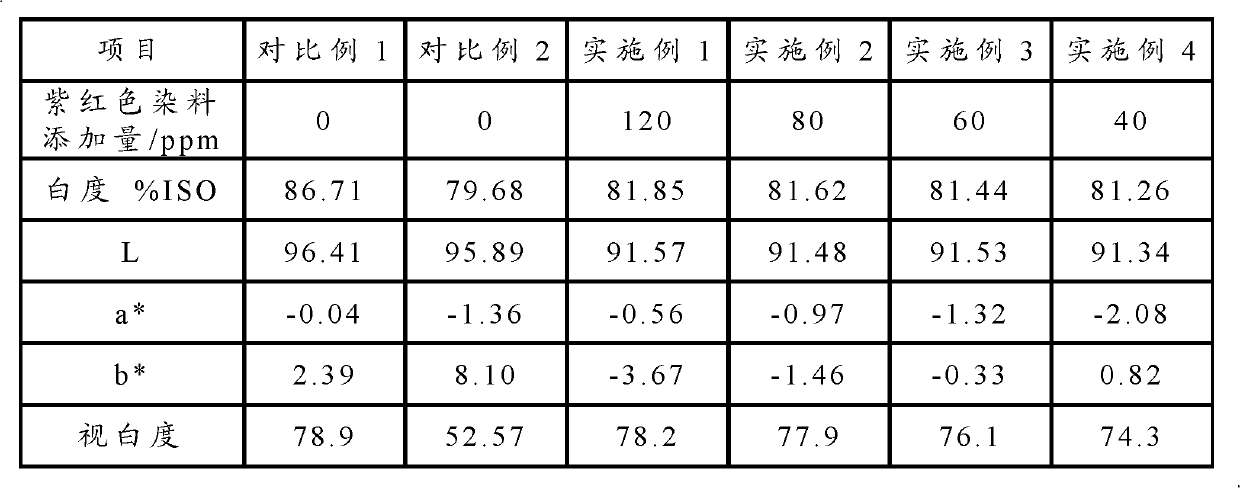

[0019] Embodiments 1-4 add different amounts of mauve dyes to the bleached chemical mechanical pulp, specifically add the dyes to the dilution water before entering the bleaching tower (see Table 1 for the specific addition amount), and the slurry after adding the dyes is mixed with the dilution water. Spiral into the bleaching tower to produce 4 kinds of bleached chemical mechanical pulp. The high-temperature bleaching and high concentration in the bleaching tower are conducive to the adsorption of dyes on the surface of the slurry, thereby increasing the retention rate of dyes.

Embodiment 5-8

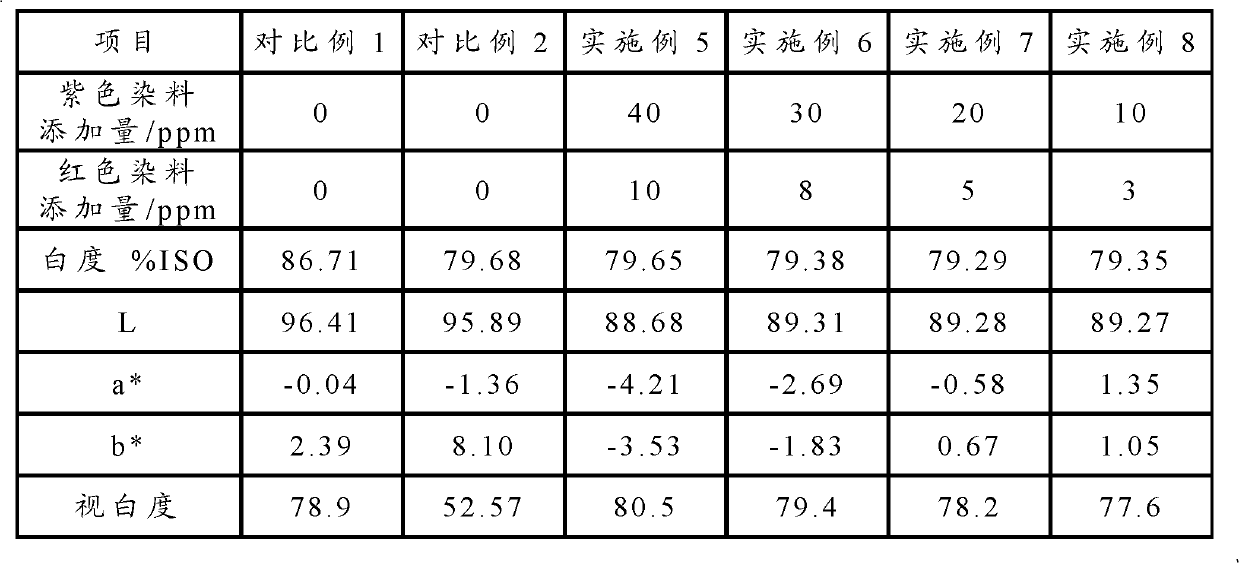

[0029] Examples 5-8 Add different amounts of purple dyes and red dyes to the bleached chemical mechanical pulp, specifically add dyes to the pulp at the entrance of the low consistency mill (see Table 2 for the specific addition amount), and respectively prepare 4 kinds Bleached chemical mechanical pulp. The high temperature generated by refining is beneficial to the retention ability of dyes on the surface of the slurry and the efficiency of dyes.

[0030] Please refer to Table 2 for the test results of brightness and apparent brightness of the four bleached chemical mechanical pulps prepared in Examples 5-8 and comparative pulps 1 and 2.

[0031] Table II

[0032]

[0033] It can be seen from Table 2 that after adding purple dye and red dye at the same time, the brightness of bleached chemical mechanical pulp pulp is greatly improved.

Embodiment 9-12

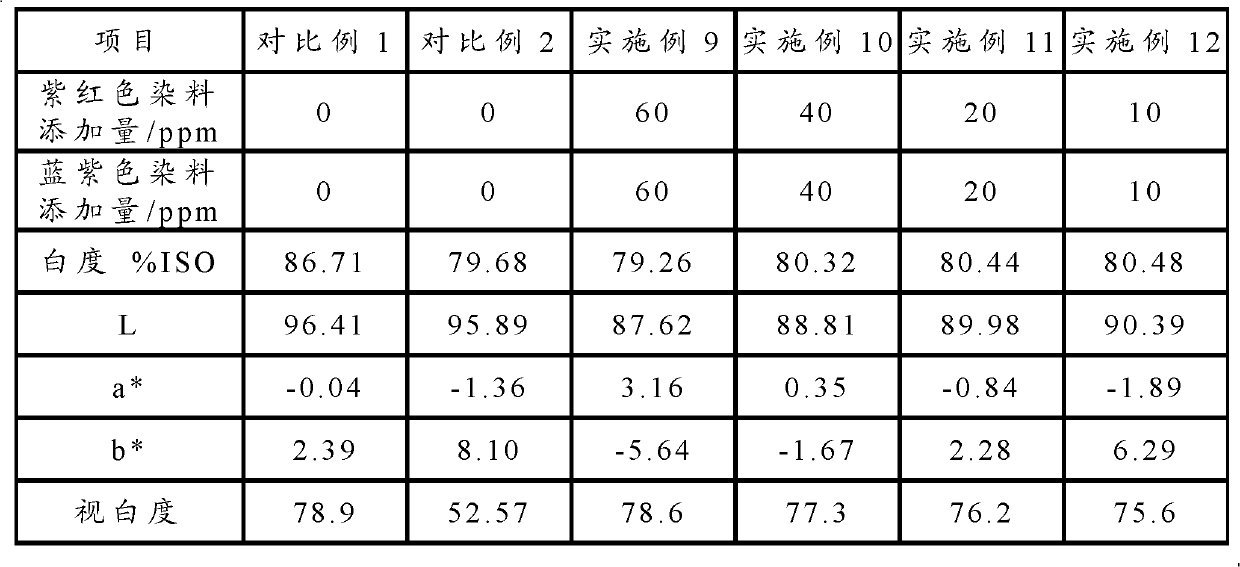

[0035] Examples 9-12 Add different amounts of purple dyes and blue-violet dyes to the bleached chemical mechanical pulp, specifically add dyes to the slurry in the dehydration tank (please refer to Table 3 for the specific addition amount), and respectively prepare 4 A bleached chemical mechanical pulp. Due to the low concentration of the slurry in the dehydration pool, it is more suitable for the addition of dyes and is conducive to uniform mixing. At the same time, it can avoid the formation of excessively dyed slurry fibers in the slurry, which will have a negative impact on the quality of papermaking.

[0036] Please refer to Table 3 for the test results of brightness and apparent brightness of the four bleached chemical mechanical pulps prepared in Examples 9-12 and comparative pulps 1 and 2.

[0037] Table three

[0038]

[0039] It can be seen from Table 3 that after adding the purple dye and the blue-violet dye at the same time, the brightness of the bleached chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com