Paper craft and paper

A papermaking process and paper technology, applied in paper, papermaking, textiles and papermaking, etc., can solve problems such as carcinogenicity, adverse effects of fluorescent whitening agents and dye raw materials on human health, achieve high visual whiteness, improve visual whiteness, The effect of high light scattering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

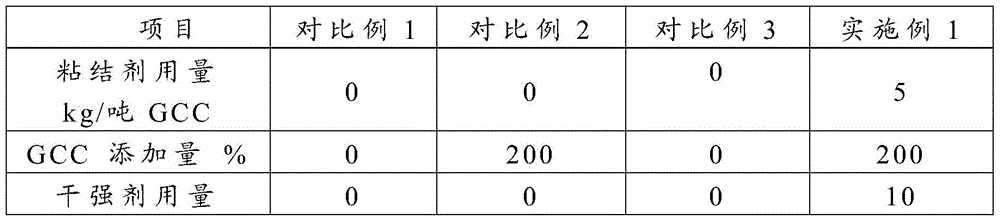

Embodiment 1

[0034] Preparation of modified GCC: Dilute the binder (cationic polyacrylamide, molecular weight 5 million) to a certain concentration of 10%, add GCC, and control the amount of binder added at 5kg / ton of GCC.

[0035] The slurry uses APMP slurry (without brighteners and dyes), and adds modified GCC to the APMP slurry (the amount of GCC in the modified GCC is 200% of the absolute dry slurry), and mixes evenly after adding the modified GCC Then add reinforcing agent (anionic guar gum, 10kg / ton of pulp), mix well, then add fixative (polyamide epichlorohydrin, 10kg / ton of pulp), mix well, and then make handmade paper.

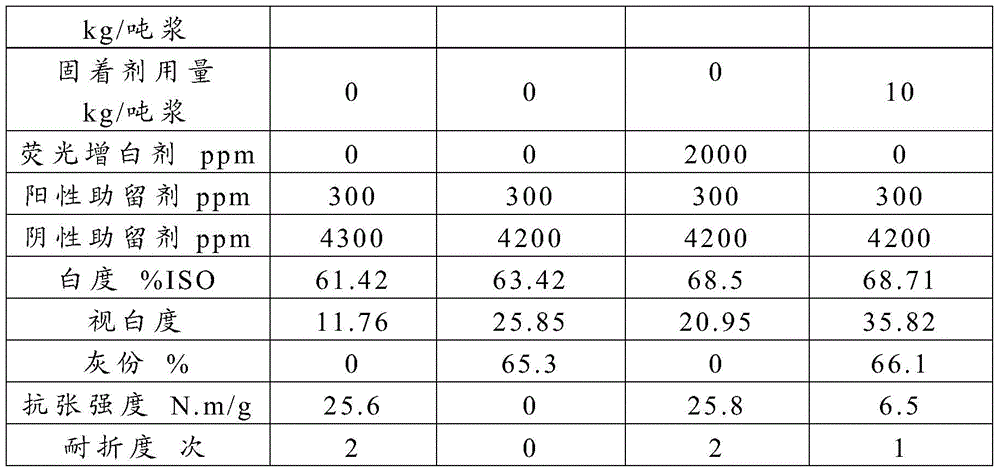

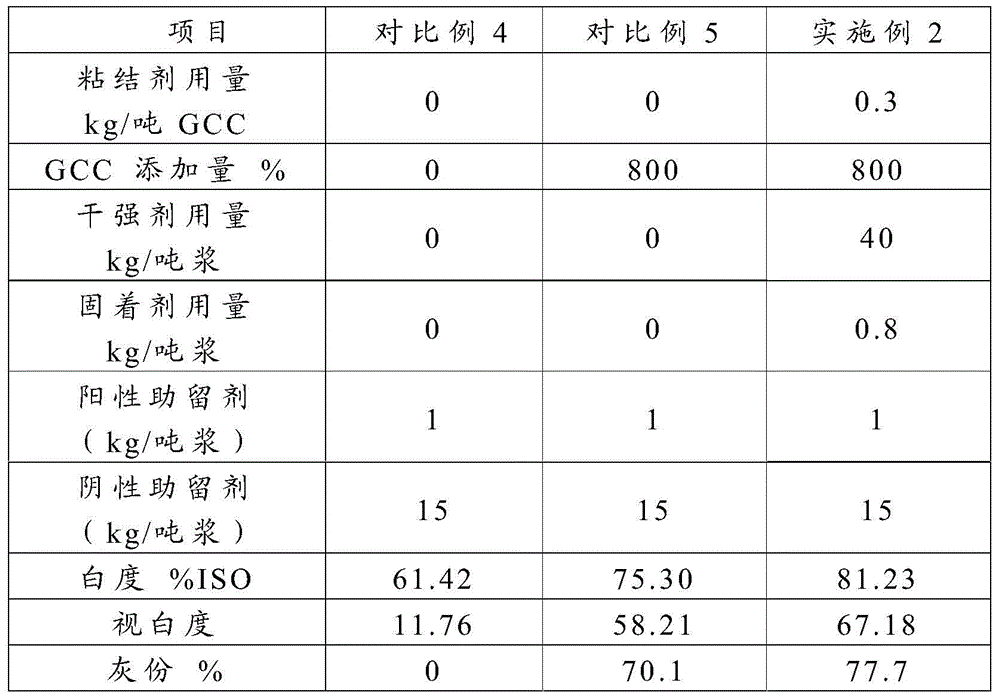

Embodiment 2

[0048] Preparation of modified GCC: Dilute the binder (anionic polyacrylamide, molecular weight: 10 million) to a certain concentration of 0.1%, add GCC, and control the amount of binder added at 0.3kg / ton of GCC.

[0049] The slurry uses the same APMP slurry as in Example 1, and the modified GCC is added to the APMP slurry (the amount of GCC in the modified GCC is 800% of the dry slurry), and after adding the modified GCC and mixing evenly Add reinforcing agent (cationic starch, 40kg / ton of pulp), mix well, then add fixative (anionic polyacrylamide, molecular weight 5 million, 0.8kg / ton pulp), mix well, and then make paper by hand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com