Oligothiophene derivative and preparation method thereof

A technology of oligothiophene and derivatives, applied in chemical instruments and methods, color-changing fluorescent materials, organic chemistry, etc., can solve problems such as unstable color changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

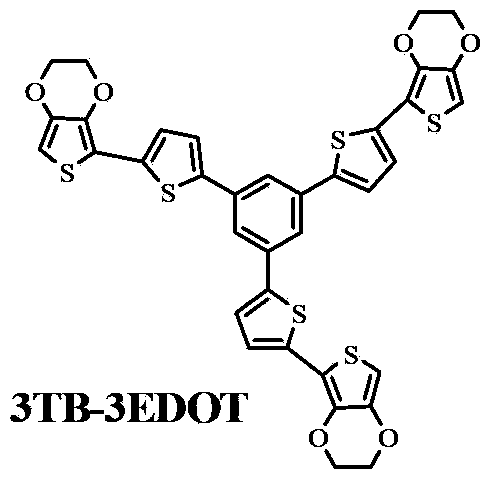

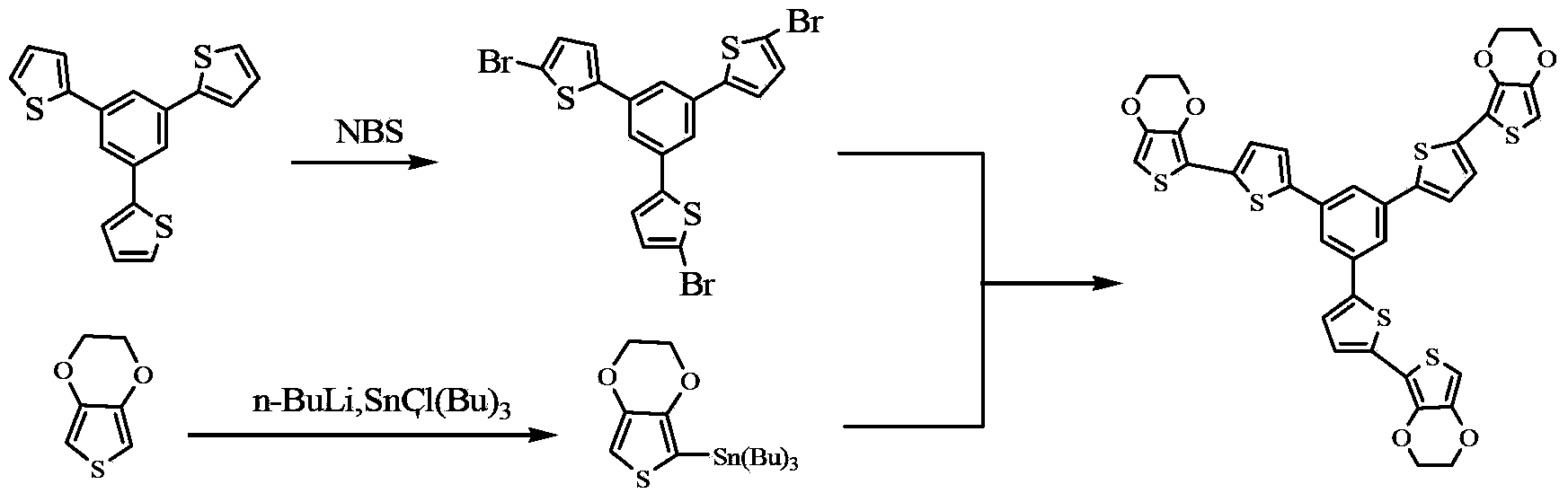

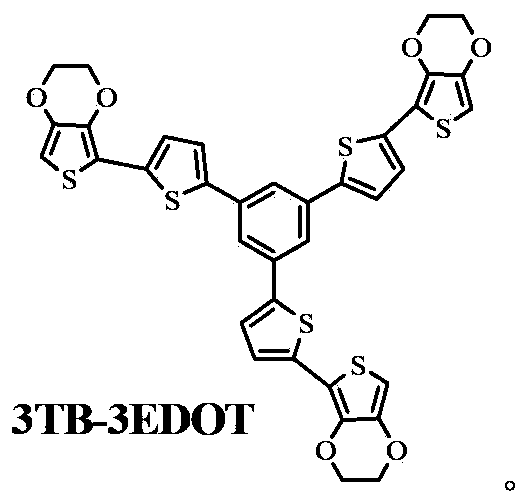

[0018] Example 1: Preparation of 1,3,5-tri[5',2"-(3",4"-dioxyethylene-thienyl)-2'-thienyl]benzene (3TB-3EDOT)

[0019] The first step is to add 1,3,5-tris(2′-thienyl)-benzene (3TB) into the Erlenmeyer flask, dissolve it with dichloromethane, and add N-bromosuccinimide under magnetic stirring (NBS), reacted at room temperature for 20 hours. The solvent was removed to give a crude product of 1,3,5-tris(5'-bromo-2'-thienyl)benzene (3TB-3Br). Using petroleum ether as a flushing liquid, the purer 3TB-3Br is obtained by separation with a chromatographic column, and then recrystallized to obtain pure 3TB-3Br.

[0020] In the second step, under the protection of nitrogen, 3,4-dioxyethylenethiophene (EDOT) and anhydrous tetrahydrofuran were added into a three-necked flask, and the reaction temperature was controlled at -78°C. After the temperature was stabilized, n-butyllithium was added dropwise, and after the dropwise addition, the temperature was raised to room temperature, and th...

Embodiment 2

[0027] Example 2: Preparation of 1,3,5-tris[5',2"-(3",4"-dioxyethylene-thienyl)-2'-thienyl]benzene (3TB-3EDOT)

[0028] The first step is to add 1,3,5-tris(2′-thienyl)-benzene (3TB) into the Erlenmeyer flask, dissolve it with dichloromethane, and slowly add N-bromosuccinyl under magnetic stirring imine (NBS), reacted at room temperature for 20 hours. The solvent was removed to give a crude product of 1,3,5-tris(5'-bromo-2'-thienyl)benzene (3TB-3Br). Using petroleum ether as a flushing liquid, the purer 3TB-3Br is obtained by separation with a chromatographic column, and then recrystallized to obtain pure 3TB-3Br.

[0029] In the second step, under the protection of nitrogen, 3,4-dioxyethylenethiophene (EDOT) and anhydrous tetrahydrofuran were added into a three-necked flask, and the reaction temperature was controlled at -78°C. After the temperature stabilized, n-butyllithium was slowly added dropwise, and after the dropwise addition, it was raised to room temperature, and t...

Embodiment 3

[0036] Example 3: Preparation of 1,3,5-tri[5',2"-(3",4"-dioxyethylene-thienyl)-2'-thienyl]benzene (3TB-3EDOT)

[0037]The first step is to add 1,3,5-tris(2′-thienyl)-benzene (3TB) into the Erlenmeyer flask, dissolve it with dichloromethane, and slowly add N-bromosuccinyl under magnetic stirring imine (NBS), reacted at room temperature for 20 hours. The solvent was removed to give a crude product of 1,3,5-tris(5'-bromo-2'-thienyl)benzene (3TB-3Br). Using petroleum ether as a flushing liquid, separate with a chromatographic column to obtain relatively pure 3TB-3Br, and then recrystallize to obtain pure 3TB-3Br.

[0038] In the second step, under the protection of nitrogen, 3,4-dioxyethylenethiophene (EDOT) and anhydrous tetrahydrofuran were added into a three-necked flask, and the reaction temperature was controlled at -78°C. After the temperature stabilized, n-butyllithium was slowly added dropwise, and after the dropwise addition, the temperature was raised to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com