Alignment mark for exposure device

A technology for aligning marks and exposure devices, which is used in photolithography process exposure devices, microlithography exposure equipment, optics, etc. efficiency, and the effect of improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 2 As shown, the existing lithography exposure device includes an exposure light source 101, left and right coaxial alignment detection devices 102a and 102b, a reticle 103, a mask mark 104, a mask table 105, a projection objective lens 106, and an off-axis alignment detection device 107 , the substrate 108, which may be glass, silicon wafer or other semiconductor materials, the substrate mark 109, the reference plate 110, the reference plate material here may be quartz, glass, silicon wafer or other materials, and the workpiece stage 111.

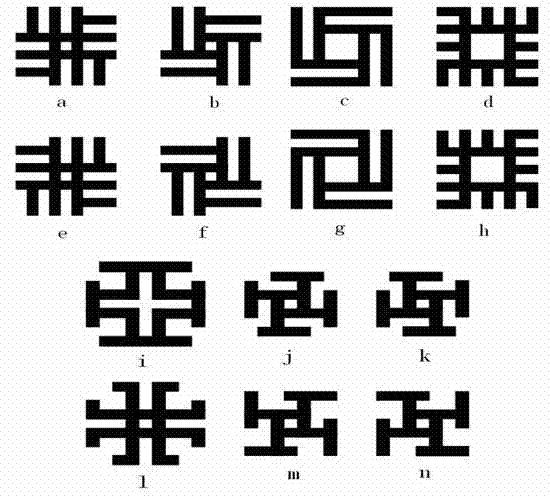

[0023] Such as image 3 Shown in a-n is a structural schematic diagram of a specific embodiment of the alignment mark of the present invention. The alignment marks a-n all meet the following characteristics at the same time: a. The alignment marks are integrally connected, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com