Method for identifying in-place oil display in presence of drilling fluid solid-state fluorescent additive

A drilling fluid and additive technology, applied in the direction of nuclear magnetic resonance analysis, etc., can solve problems such as difficult quantification, poor discrimination, and lower oil level of oil layer cuttings, and achieve the effect of easy operation, simple method, and improved exploration and development benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

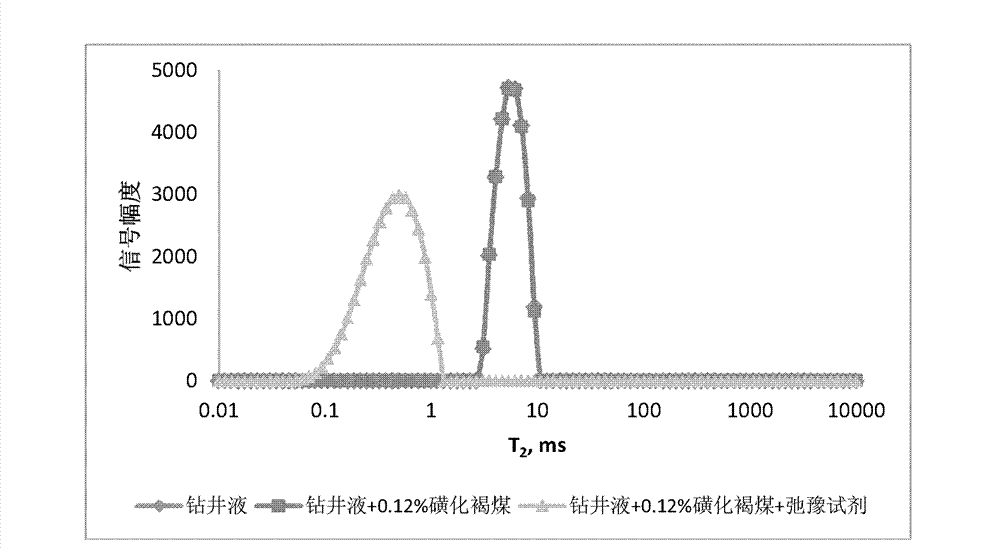

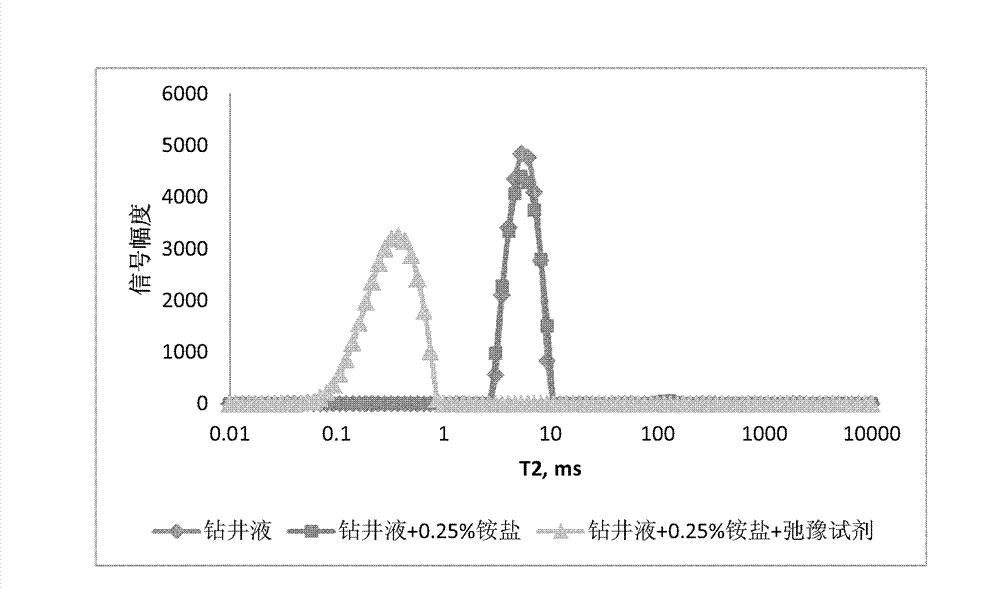

[0036] During the construction of Well S14-7, 2t of sulfonated asphalt was mixed into the well at a depth of 1490m. NMR analysis is carried out after sampling, and then relaxation reagents are added for continuous NMR analysis. The results are shown in Figure 5 and Figure 6 .

[0037] pass Figure 5 and Figure 6 It can be seen that the T2 spectrum of drilling fluid + 2t sulfonated bitumen is a peak with a peak area of 26453.97, while the NMR T2 spectrum of drilling fluid + 2t sulfonated bitumen + relaxation reagent is still a peak. Subsequently, the relaxation reagent was added continuously at a distance of 2m for analysis, and a new display peak was found at the well depth of 2036m, which was judged to be formation crude oil display. Segments are interpreted as oil layers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com