Gas/liquid corrosion simulation test device and test method

A technology for simulating test and corrosion reaction. It is used in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problems of small number of samples, complex structure, toxic gas leakage, etc., and achieve simple structure and high control accuracy. , the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

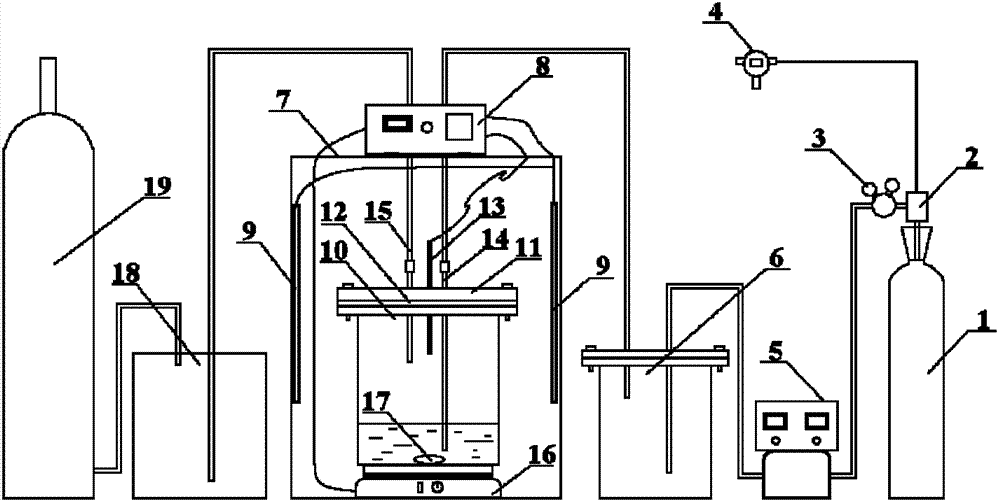

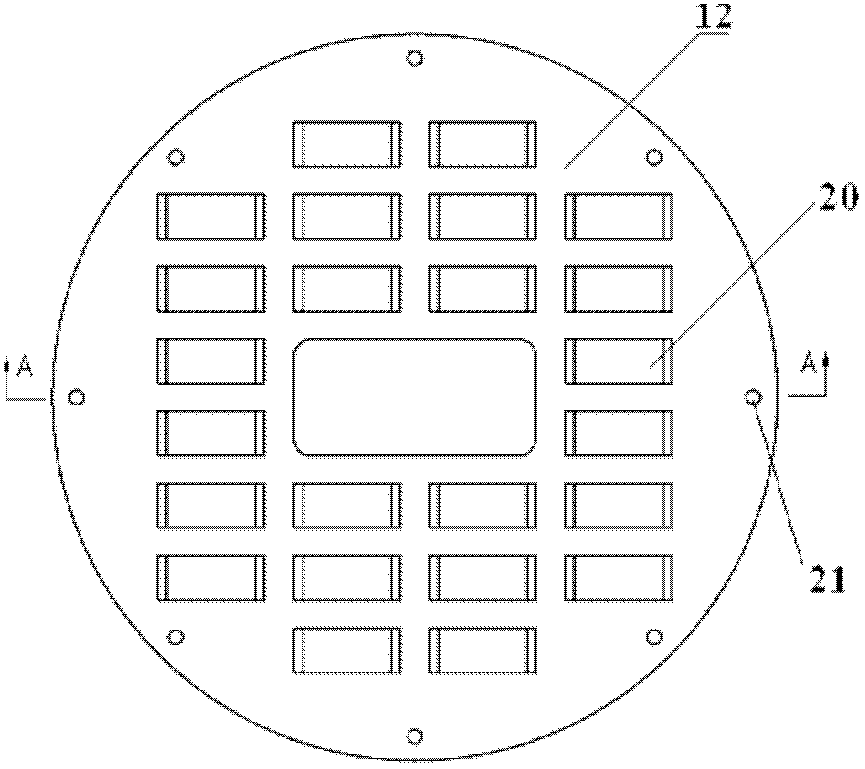

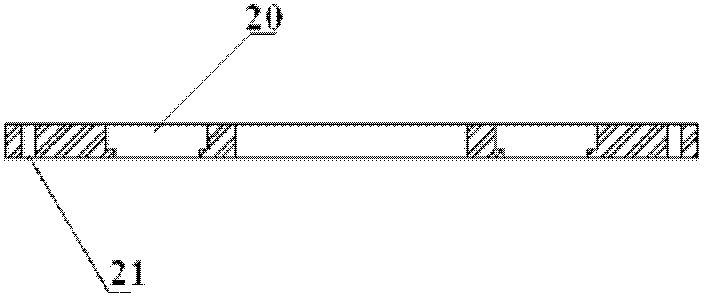

[0018] Embodiment 1, when simulating the gas corrosion environment, for example, when simulating the corrosion environment on the upper deck of the cargo oil tank of an oil tanker, H 2 S 500ppm, O 2 4%, N 2 The steel cylinder 1 of the balance (volume percentage) mixed gas is connected to the gas path, and the sample with a size of 25mm×60mm×5mm is placed in the slot 20 of the sample holder 12, and 0.1% of the mixed gas is injected into the corrosion reaction tank 10. NaCl aqueous solution (mass percentage composition), then the sample holder 12 is fastened on the corrosion reaction tank 10 together with the corrosion reaction tank upper cover 11 with bolts, the door of the cabinet 7 is opened, and the sample holder 12 and the upper cover will be fixed. The corrosion reaction tank 10 of 11 is put into the case that heating pipe 9 is installed, connects inlet pipe 14 and outlet pipe 15, closes chamber door behind the thermocouple 13 installed. Start the programmable controller...

Embodiment 2

[0019] Embodiment 2, when simulating liquid corrosion, hang the sample on the sample holder 12 with an insulating fine wire, inject the corrosive liquid required for the test into the corrosion reaction tank 10, and then hang the sample holder 12 with the sample together with the corrosion The upper cover 11 of the reaction tank is fastened on the corrosion reaction tank 10 with bolts, the sample is completely or partially immersed in the corrosive solution according to the test requirements, the door of the box 7 is opened, and the corrosion reaction of the sample holder 12 and the upper cover 11 is installed. The tank 10 is put into the box, and the box door is closed after the thermocouple 13 is installed. Start the programmable controller 8, heat up after inputting the temperature control parameters, start timing the test when the predetermined temperature is reached, and turn off the programmable controller 8 when the predetermined test time is reached. The sample is remo...

Embodiment 3

[0020] Example 3, when simulating a static gas-liquid coexistence corrosion environment, the steel cylinder 1 containing the gas required for the test is connected to the gas circuit, the sample is suspended on the sample holder 12 with an insulating thin wire, and injected into the corrosion reaction tank 10 The corrosive solution required for the test is then fastened to the corrosion reaction tank 10 with the sample holder 12 with the sample hung on the corrosion reaction tank upper cover 11 with bolts, all or part of the sample is immersed in the corrosive solution, and the opening of the box 7 door, put the corrosion reaction tank 10 fixed with the sample rack 12 and the upper cover 11 into the box, connect the air inlet pipe 14 and the air outlet pipe 15, and close the door after installing the thermocouple 13; start the programmable controller 8 and The gas flow controller 5 inputs temperature and gas flow control parameters respectively. After the gas-tightness inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com