LED light source

An LED light source and reflector technology, applied in the field of LED lighting, can solve the problems of insufficient lighting uniformity, light scattering obstruction, light waste, etc., and achieve the effect of improving the utilization rate of luminous flux, improving the uniformity of road lighting, and reducing light waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

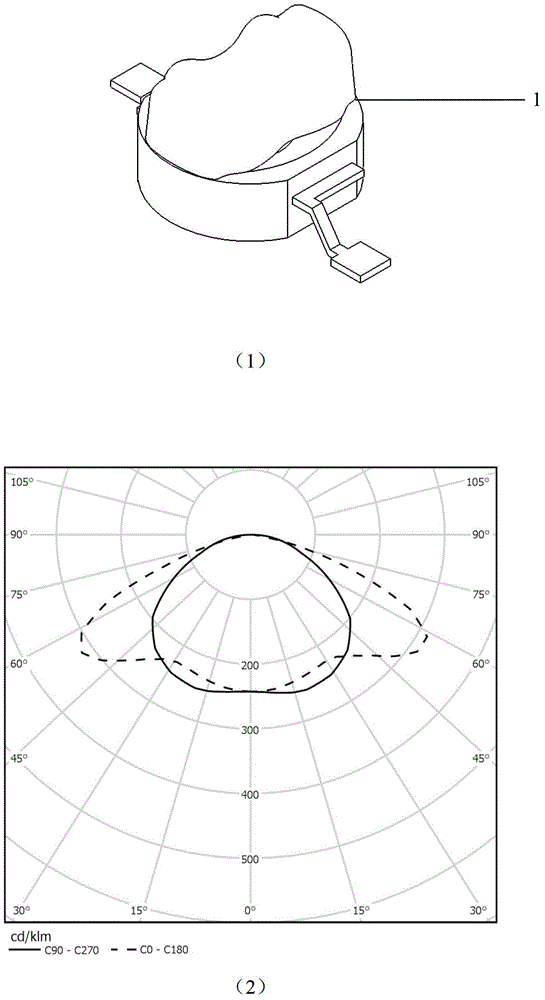

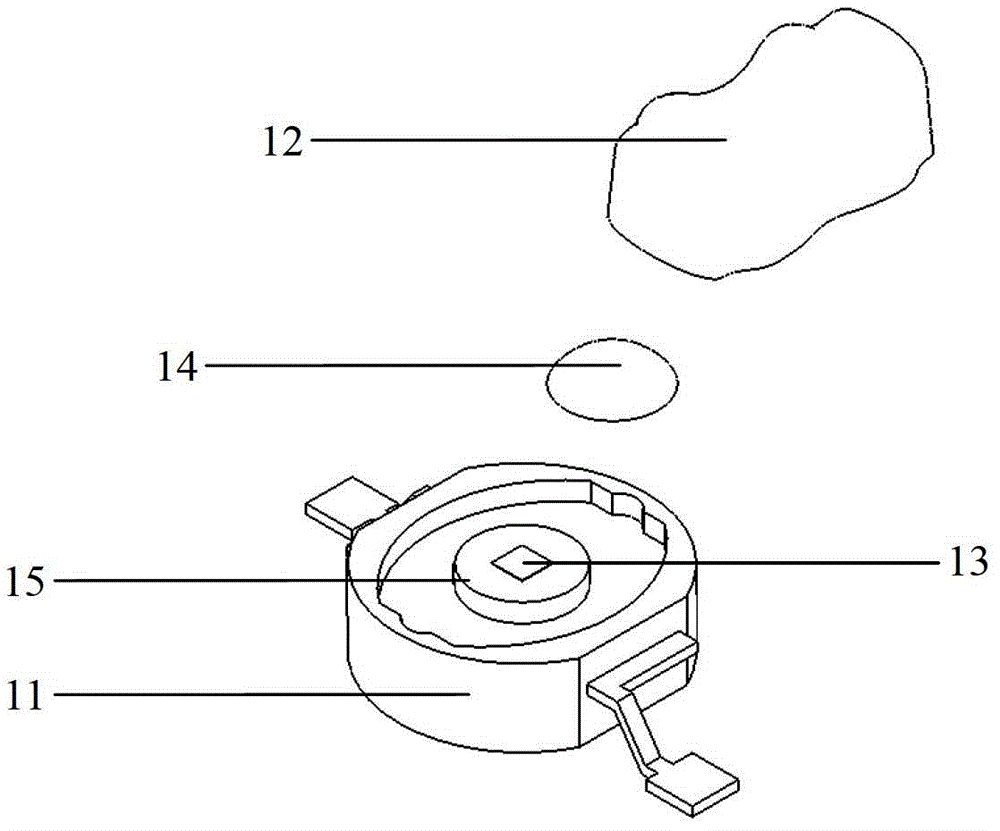

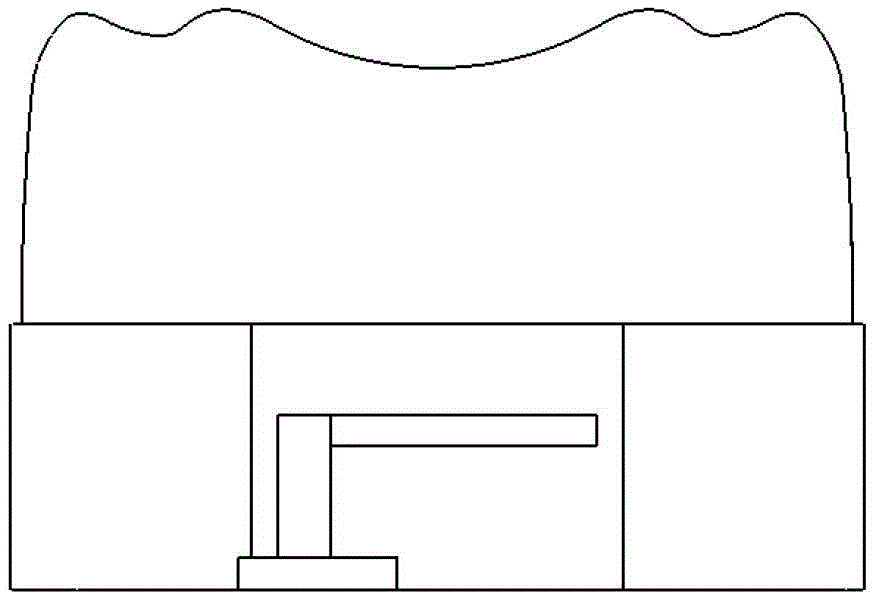

[0071] refer to figure 1 (1), figure 2 , image 3 , figure 1 (1) Structural schematic diagrams of the LED illuminants provided in Embodiments 1, 2, 3, and 4 of the present invention, figure 2 It is a schematic diagram of the structural decomposition of the LED illuminant provided in Embodiments 1, 2, 3, and 4 of the present invention, image 3 It is the front view of the LED illuminant provided by Embodiments 1, 2, 3 and 4 of the present invention. It can be seen from the figure that the LED illuminant 1 is an LED single lamp with a multi-peak lens 12 through a light distribution process, and is composed of a packaging bracket 11 , a multi-peak lens 12 , a light-emitting chip 13 and a fluorescent glue 14 . The center of the packaging bracket 11 is a cylindrical base 15, the light-emitting chip 13 is located at the center of the upper surface of the cylindrical base 15, and the fluorescent glue 14 is coated on the upper surface of the cylindrical base 15 and wraps the lig...

Embodiment 2

[0078] refer to Figure 12 , Figure 13 , Figure 14 , Figure 12 It is a schematic structural diagram of the reflector group provided in Embodiment 2 of the present invention, Figure 13 It is an exploded schematic diagram of the structure of the reflector group provided in Embodiment 2 of the present invention, Figure 14 It is a schematic structural diagram of the LED light source provided in Embodiment 2 of the present invention; it can be seen from the figure that the reflector group 2 is composed of two reflector units, which are reflector unit one 21, reflector unit two 22, and two reflector units respectively. The reflector units are not connected, and the first reflector unit 21 and the second reflector unit 22 have different structures and are respectively located on the front and rear sides of the LED illuminant 1 . The surface treatment of the reflector group 2 is a smooth surface such as vacuum aluminum plating, chrome plating, or silver plating, which is a sp...

Embodiment 3

[0083] refer to Figure 17 , Figure 18 , Figure 19 , Figure 17 It is a schematic structural diagram of the reflector group provided in Embodiment 3 of the present invention, Figure 18 It is an exploded schematic diagram of the structure of the reflector group provided by Embodiment 3 of the present invention, Figure 19 The structural representation of the provided LED light source for the present invention's implementation three; as can be seen from the figure, the reflector group 2 is made up of two reflector units, which are respectively reflector unit one 21, reflector unit two 22, two reflector units The reflector units are not connected, and reflector unit one 21 and reflector unit two 22 have different structural forms and are respectively located on the front and rear sides of the LED illuminant 1 . The surface treatment of the reflector group 2 is a smooth surface such as vacuum aluminum plating, chrome plating, or silver plating, which is a specular reflectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com