Bonding sheet for manufacturing semiconductor device, semiconductor device and manufacturing method thereof

A manufacturing method, semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, adhesives, etc., can solve problems such as positioning difficulties, affecting the productivity of semiconductor devices, warpage of lead frames or wiring substrates, etc., to improve productivity and suppress The effect of mold flashing phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1

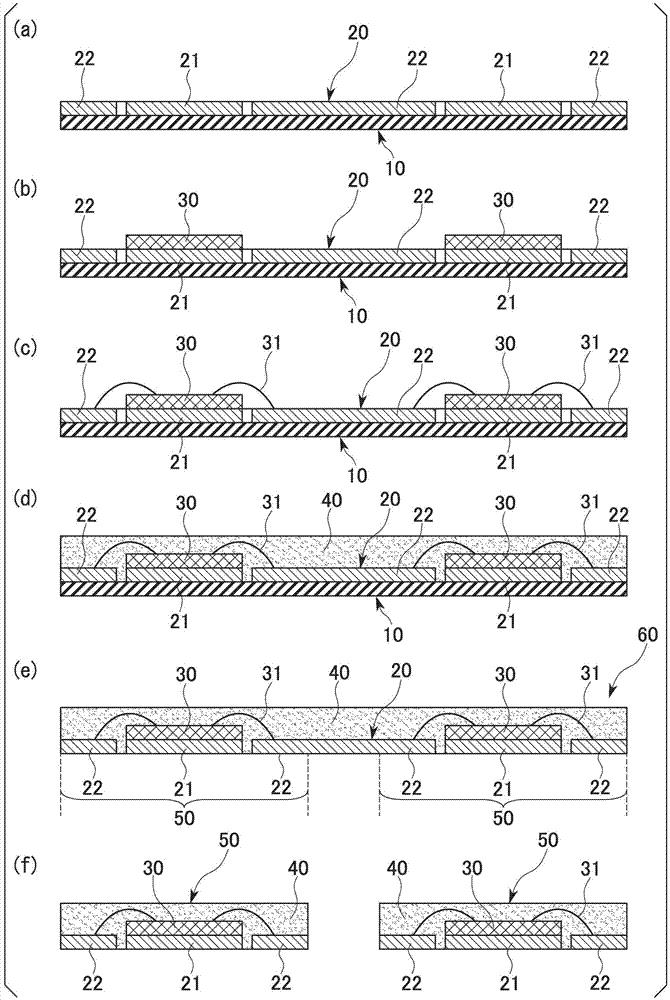

[0148] According to the composition shown in Table 1, each raw material was dispersed in an appropriate amount of toluene, and a binder coating liquid was prepared respectively.

[0149] Then, a polyimide resin film (manufactured by DuPont Toray, trade name: kapton100EN, thickness 25 μm, glass transition temperature 300° C. or higher, thermal expansion coefficient 16 ppm / ° C.) was prepared as a heat-resistant base material. The above-mentioned adhesive coating solution was coated thereon in such an amount that the thickness after drying was 5 μm. In addition, the size of the adhesive sheet was 60 mm in length and 50 mm in width. After applying the adhesive coating liquid, it was dried at 150° C. for 3 minutes to obtain the adhesive sheet of each example. For the obtained adhesive sheet, the adhesive strength a before heating, the adhesive strength b after heating, the adhesive strength c after heating, the amount of warpage, and the number of resin leaks were measured, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com