Ti-Ni based shape memory alloy vacuum electron beam connecting technology

A technology of vacuum electron beam and memory alloy, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of no patent application, etc., and achieve strong penetration ability, good connection, and high energy conversion rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The material is a Ti-Ni shape memory alloy plate, wherein the size is 100×55×4mm; the alloy composition is Ti: 49.2at%, Ni: 50.8at%.

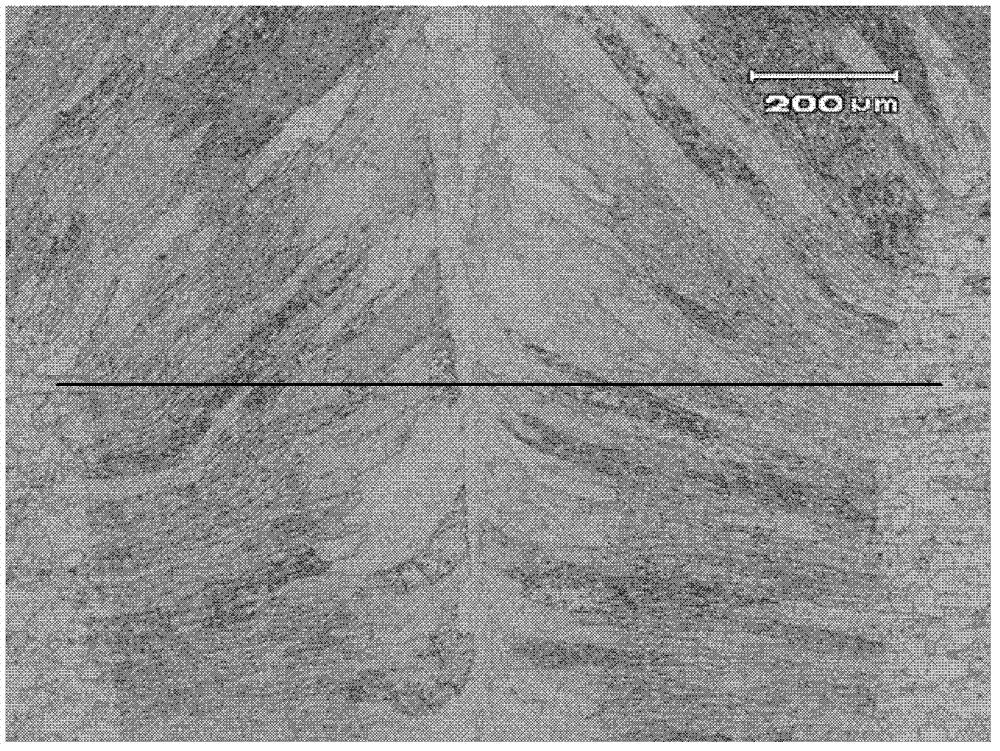

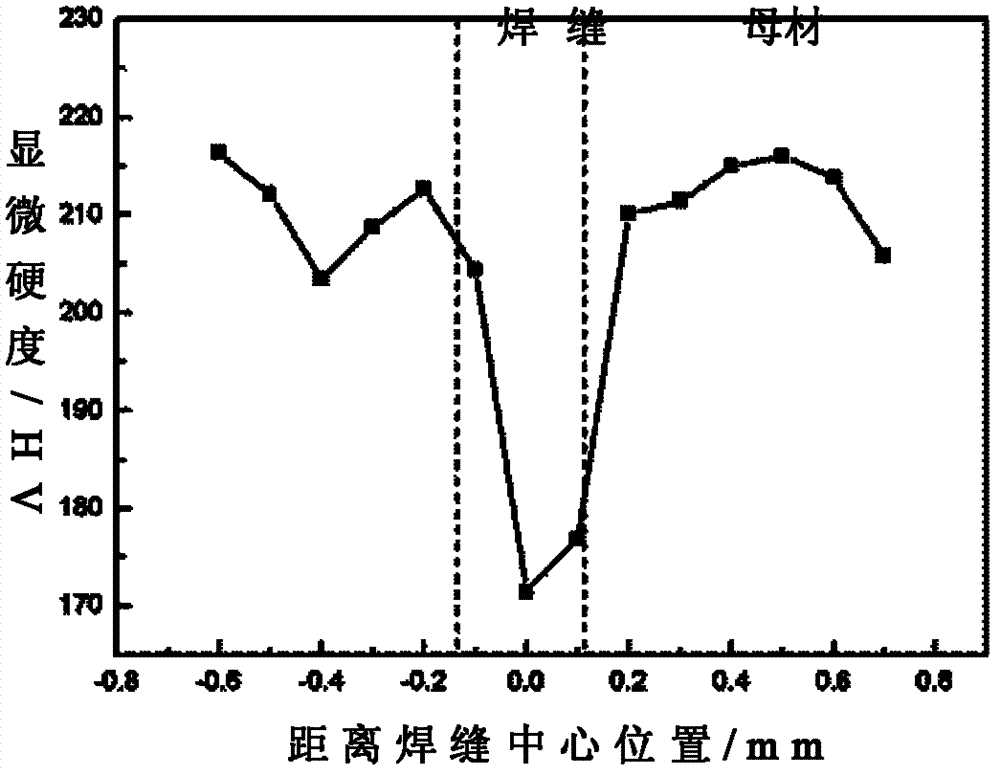

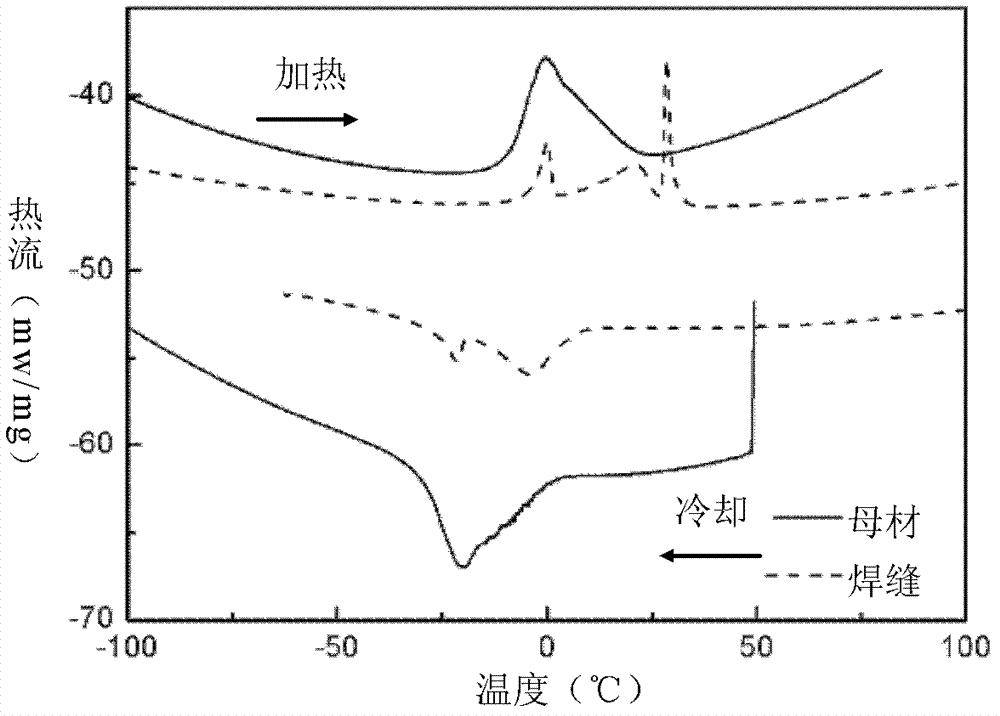

[0030] Firstly, the Ti-Ni shape memory alloy with nearly equiatomic ratio is smelted. After 1073K hot rolling into 4mm thick plate, solution treatment at 860℃ for 40min. Then, carry out surface treatment on the Ti-Ni base shape memory alloy plate to be welded, and then use acetone and alcohol solvent to ultrasonically clean it to remove oil stains, and dry it; secondly, measure the size of the cleaned workpiece and place it in a vacuum chamber. The fixture is fixed, the program is set, and the position of the plate is adjusted so that the electron beam can accurately hit the place to be welded, and then vacuum, the vacuum degree is 10 -2 ~10 -3 Pa; again, the electron beam is focused to ensure that the weld is well formed, and the program is started, and the electron beam starts welding from one end of the plate until the other end. W...

Embodiment 2

[0035] Material Ti-Ni-Nb wide hysteresis shape memory alloy, the specification is 90×60×3.5mm, the alloy composition is Ti: 44at%, Ni: 47at%, Nb: 9at%.

[0036] Firstly, the forged ingot is heat-preserved at 1073K, and then hot-rolled into a 4mm thick plate by a transverse universal rolling mill, and then solution treated at 860°C for 40 minutes to obtain the plate for welding. Then, the Ti-Ni-based shape memory alloy plate to be welded is subjected to mechanical processing surface treatment, and then ultrasonically cleaned with acetone and alcohol solvents to remove oil stains and dried; secondly, the cleaned workpieces are butted and placed in a vacuum chamber. Fix the two plates with clamps, and then vacuum, the vacuum degree is 10 -2 ~10 -3 Pa; again, focus the electron beam to the butt joint gap of the two plates, and start welding from one end of the gap until the other end. Welding parameters are as follows: welding speed is 1000mm / min, accelerating voltage is 60KV, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com