Preparation method of lanthanide doped nanotube-TiO2 composite photocatalyst, and application of composite photocatalyst in VOCs treatment

A lanthanide and nanotube technology, applied in the field of environmental pollution control, can solve the problems of no catalyst catalytic performance, no catalyst application range, unknown application prospects, etc., and achieves large porosity, good adsorption performance, and efficient catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 17 mL of tetrabutyl titanate, 40 mL of absolute ethanol and 3 mL of glacial acetic acid were prepared as a mixed solution A, and the mixed solution A was slowly added dropwise to a mixed solution of 15 mL of absolute ethanol and lanthanum nitrate, and stirred for 1 After 1 h, it was aged at room temperature for 6 h until a transparent gel was formed, and the gel was washed repeatedly with ethanol, and then dried at 70 °C for 12 h. The precursor powder was formed after sufficient grinding in the mortar. The doping amount of lanthanum element in the prepared nanoparticle precursor was 1.0%wt.

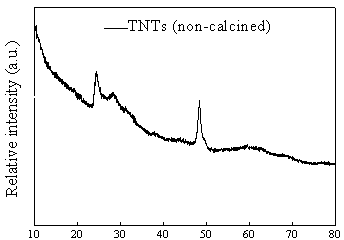

[0026] Mix 1.5 g of the prepared sol-gel powder with 120 mL of 10M NaOH solution evenly, then transfer to a 200 mL hydrothermal kettle, hydrothermally treat at 130 °C for 48 h, cool at room temperature and filter to obtain a milky white precipitate; Rinse with 0.1 M HCL solution for 5 times, and then rinse with deionized water until the cleaning solution is close to the value of d...

Embodiment 2

[0028]Prepare mixed solution A with 14 mL tetrabutyl titanate, 40 mL absolute ethanol and 3 mL glacial acetic acid, slowly add the mixed solution A to the mixed solution of 12 mL absolute ethanol and cerium nitrate, and stir for 1 h After aging at room temperature for 6 h until a transparent gel was formed, the gel was washed repeatedly with ethanol and dried at 70 °C for 12 h. The precursor powder was formed after sufficient grinding in the mortar. The doping amount of cerium element in the prepared nanoparticle precursor was 0.8%wt.

[0029] Mix 2 g of the prepared sol-gel powder with 120 mL of 10M NaOH solution evenly, then transfer it to a 200 mL hydrothermal kettle, treat it at 130 °C for 48 h, and filter it after cooling at room temperature to obtain a milky white precipitate; first Rinse 6 times with 0.1 M HCL solution, and then rinse with deionized water until the cleaning solution is close to the value of deionized water, about 6.5. After the sample was filtered and...

Embodiment 3

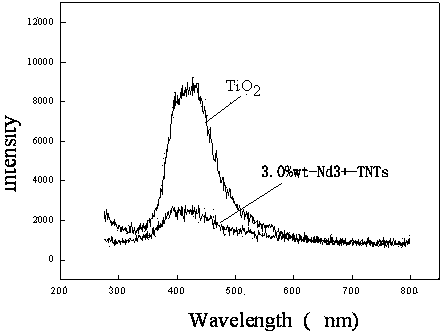

[0031] Prepare mixed solution A with 18 mL tetrabutyl titanate, 40 mL absolute ethanol and 3 mL glacial acetic acid, slowly add the mixed solution A to the mixed solution of 14 mL absolute ethanol and neodymium nitrate, and stir for 1 After 1 h, it was aged at room temperature for 6 h until a transparent gel was formed, and the gel was washed repeatedly with ethanol, and then dried at 70 °C for 12 h. The precursor powder was formed after sufficient grinding in the mortar. The doping amount of neodymium in the prepared nanoparticle precursor was 3.0%.

[0032] Mix 3 g of the prepared sol-gel powder with 120 mL of 10M NaOH solution evenly, then transfer to a 200 mL hydrothermal kettle, hydrothermally treat at 130 °C for 48 h, cool at room temperature and filter to obtain a milky white precipitate; Rinse with 0.1 M HCL solution for 5 times, and then rinse with deionized water until the cleaning solution is close to the value of deionized water, about 6.5. After the sample was f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com