A kind of emc package led lead frame deflashing process

A lead frame and anti-overflow technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of damage to epoxy resin and electroplating surface, easy damage to the surface of the plastic body and pins, low cost, etc. The effect of low cost, easy operation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

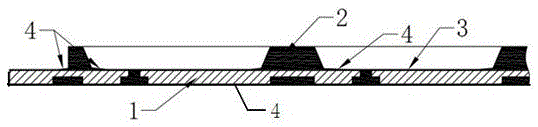

[0020] figure 1 As shown, the LED lead frame of the EMC package of the present invention is composed of a metal frame 1, an epoxy resin 2, and a silver plating layer 3 after half-packaging, but flashes 4 of different degrees will be produced during the production process. The technique of the present invention is to remove the flash 4 without damaging the metal frame 1, the epoxy resin 2, and the silver-plated layer 3. The specific method comprises the following steps: a process for removing flash from an EMC package LED lead frame, characterized in that, The process includes the following steps, 1) electrolysis, 2) air knife, 3) water washing, 4) high-pressure water knife, 5) scrubbing, 6) neutralization, 7) protection, and 8) drying. The main purpose of rinsing in this process is to rinsing the residual overflow, the purpose of neutralization is to neutralize the alkalinity generated during electrolysis, and the purpose of protection is to soak the silver layer protective so...

Embodiment 2

[0022] As a further improvement of the present invention, the high-pressure water knife also includes the following steps, 4.1 Washing with water, continuing to clean the residual overflow, 4.2 Air knife, drying the water and keeping it dry; wherein the function of the high-pressure water knife is to rinse the residual overflow.

Embodiment 3

[0024] As a further improvement of the present invention, the step 5 brushing also includes the following steps, 5.1 washing with water, and continuing to clean the residual overflow, wherein the brushing is mainly to wash away the residual overflow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com