Modular solar chemical adsorption heat storage and release and temperature-raising system and method

A chemical adsorption, solar energy technology, applied in the field of solar energy storage, can solve the problems of places that cannot meet high temperature requirements, low adsorbate evaporation pressure, limited system use, etc., to achieve good portability and maintainability, improve Evaporation pressure, the effect of improving system efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

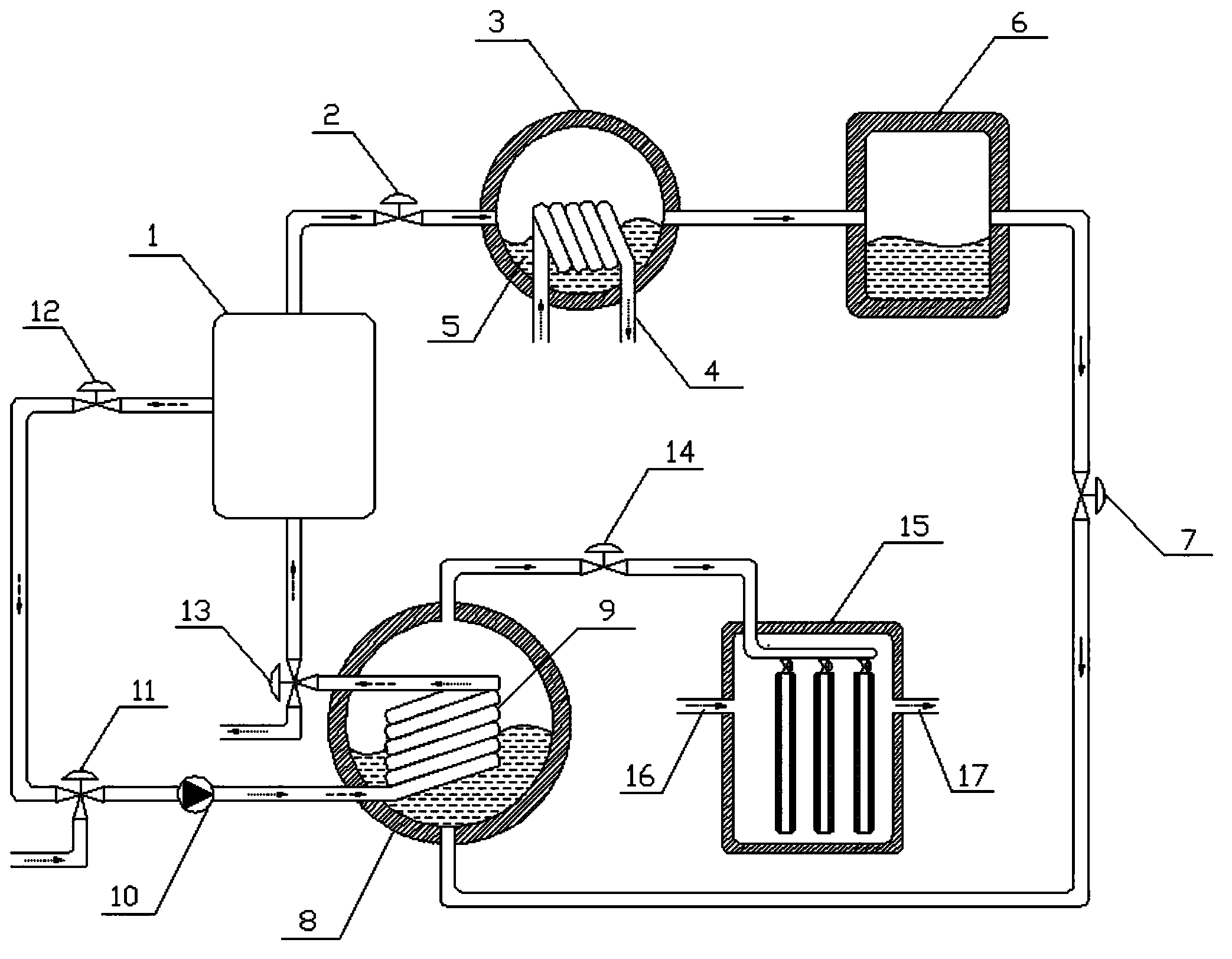

[0042] figure 1 Among them, a modularized solar chemical adsorption heat storage and temperature raising system in this embodiment includes a heat collection and energy storage device 1, a heat storage valve 2, a condenser 3, a liquid storage device 6, a throttle valve 7, and an evaporator 8 , heat transfer fluid circulation pump 10, switching valve 11, temperature rise valve 12, return valve 13, heat release valve 14, heat exchange unit 15, heat exchange fluid inlet pipeline 16, heat exchange fluid outlet pipeline 17, inside the condenser 3 A condenser heat exchange coil 4 is provided and an adsorbate 5 is installed; the evaporator 8 is provided with an evaporator heat exchange coil 9 and an adsorbate 5 is installed.

[0043] The upper outlet of heat collection and energy storage device 1 is connected to the inlet of condenser 3 through heat storage valve 2, the outlet of condenser 3 is connected to the inlet of liquid storage 6, the outlet of liquid storage 6 is connected to...

Embodiment 2

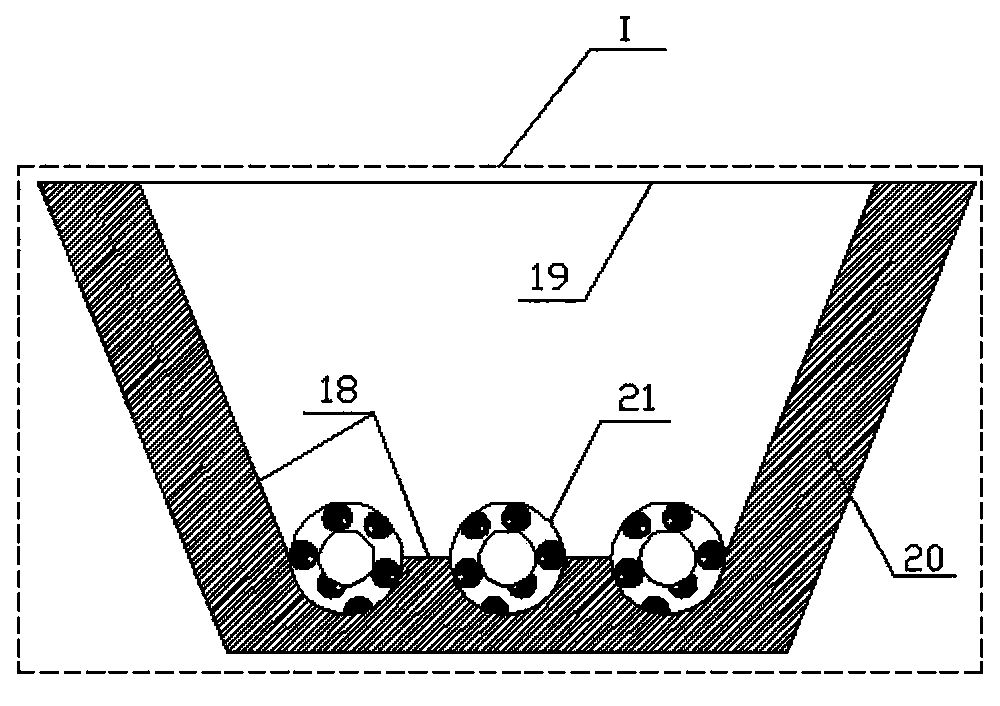

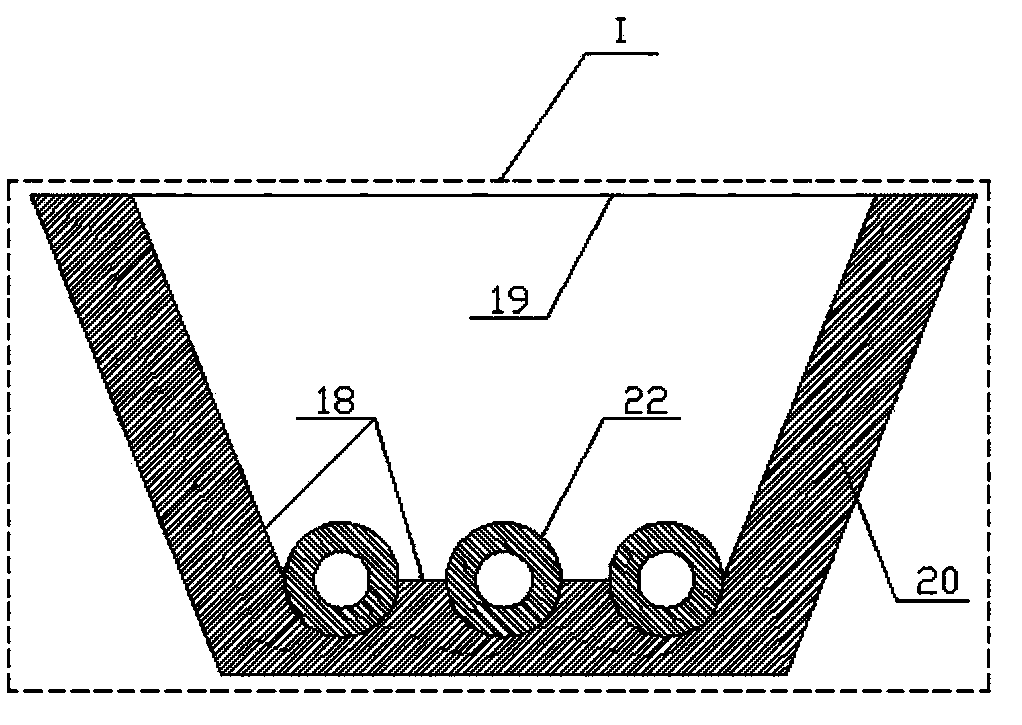

[0054] In the modularized solar medium and long-term chemical adsorption heat storage and heat release and temperature raising system of this implementation example, the thermal energy storage device 1 adopts such as Figure 4 The vacuum tube type structure shown.

[0055] In this embodiment, the heat storage module 21 is filled with a mixture of LiBr and graphite, the heat exchange fluid is water, and there is no light concentrating structure.

[0056] The rest of the process of this implementation example is the same as that of Example 1.

[0057] In this implementation example, the energy storage density of the system is about 2600KJ / Kg and the energy release temperature is about 58°C when the ordinary heat release method is adopted; the energy release temperature of the system is about 90°C when the heat release method with heating is used. Compared with the normal exothermic method, the exothermic method with elevated temperature increases the exothermic temperature by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com