Anti-loose and fastening connecting method and system through thread extrusion

A connection method and a connection system technology, applied in the field of component connection methods and systems, can solve the problems of complex disassembly, large space for connected parts, and high installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The thread extrusion anti-loosening fastening method provided in this embodiment 1 is A. The anti-rotation torque M obtained by the joint action of the new design of the thread profile of the nut and the bolt, the soft and hard configuration of the nut and the bolt material, and the new size of the nut. 1 . The corresponding thread extrusion anti-loosening fastening connection system is also A. The new design of the nut and bolt thread profile, the soft and hard configuration of the nut and bolt material, and the new size of the nut all have three.

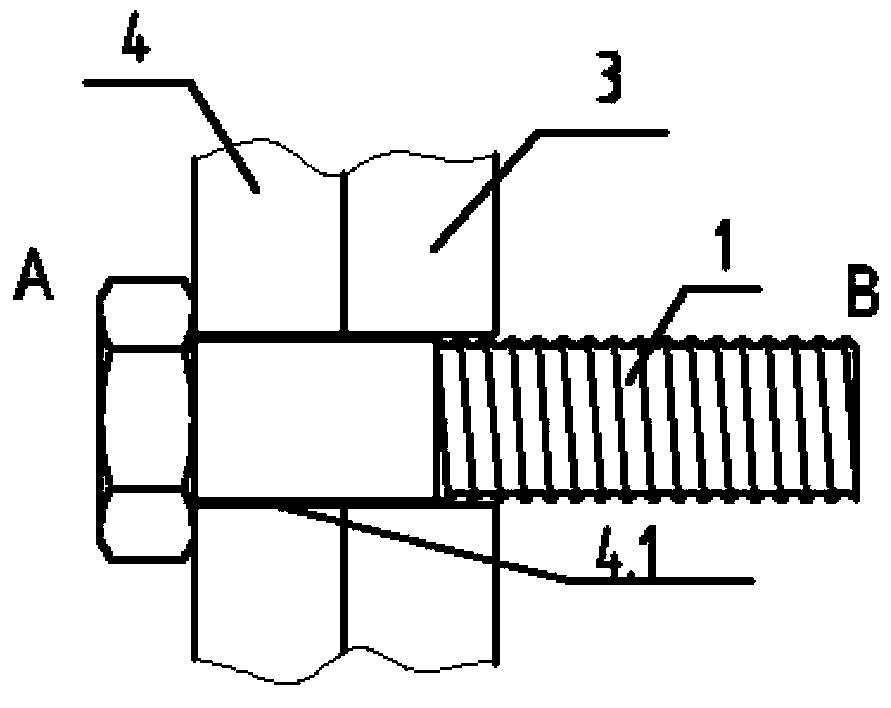

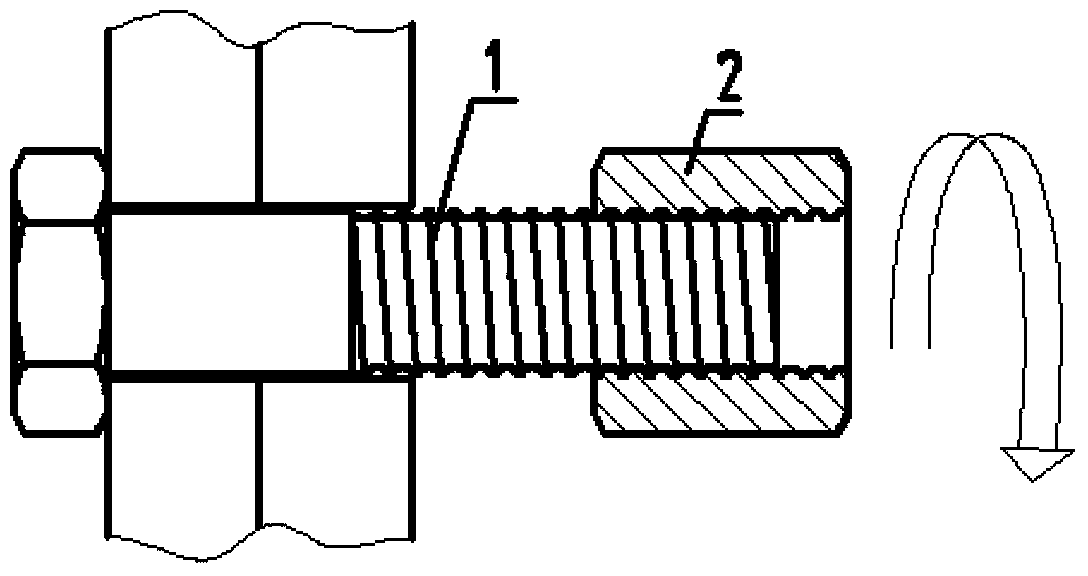

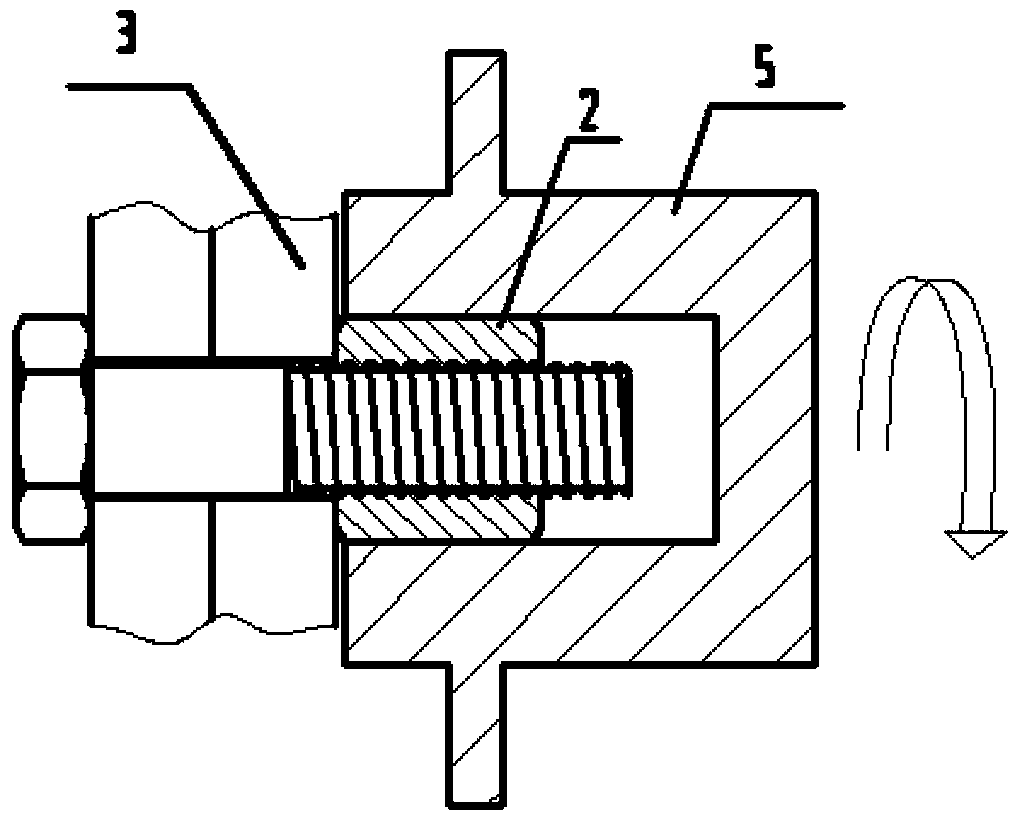

[0033] See figure 1 -- Figure 4 , the present embodiment 1 thread extrusion anti-loosening fastening method has the following steps:

[0034] 1) see figure 1 , insert the bolt 1 from the front side A of the two connected parts 4 and 3 into the installation hole 4.1. 2) see figure 2 , screw the nut 2 on the outside of the bolt 1 from the rear side B of the two connected parts. 3) see image 3 , Use a torque wrench ...

Embodiment 2

[0045] The thread extrusion anti-loosening fastening method provided in this embodiment 2 is B. The new design of the thread profile of the nut and the bolt and the soft and hard configuration of the nut and the bolt material work together to obtain the value of the anti-rotation torque M2. Correspondingly provided thread extrusion anti-loose fastening connection system is B. Nut and bolt thread profile new design and soft and hard configuration of both nut and bolt materials.

[0046] Embodiment 2 is identical to Embodiment 1 except for the following features.

[0047] The value of the anti-rotation torque M2 in the thread extrusion anti-loosening fastening method of the second embodiment is shown in the following table 6:

[0048] Table 6

[0049]

[0050] It can be seen from Table 6 that the obtained anti-rotation torque M 2 Is the value range of anti-rotation torque in Table 1 M 0 the lower limit value of .

[0051] In this embodiment 2, the thread extrusion anti-lo...

Embodiment 3

[0055] The thread extrusion anti-loosening fastening method provided in Example 3 is C. The new design of the thread profile of the nut and the bolt and the new size of the nut work together to obtain the value of the anti-rotation torque M3. Its corresponding thread extrusion anti-loosening fastening connection system is C. Both the new design of the thread profile of the nut and the bolt and the new size of the nut have both.

[0056] Embodiment 3 is identical to Embodiment 1 except for the following features.

[0057] The value of the anti-rotation torque M3 in the steps of the thread extrusion anti-loosening fastening connection method is the value in Table 7.

[0058] Table 7

[0059]

[0060] It can be seen from Table 7 that the obtained anti-rotation torque M 3 Is the value range of anti-rotation torque in Table 1 M 0 upper bound value of .

[0061] In this embodiment 3, the screw extrusion anti-loosening fastening connection system adopts the new design of the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com