High-strength locking nut

A lock nut, high-strength technology, applied in the direction of nuts, lock fasteners, screws, etc., can solve the problems of high cost, loss, and weak connection, and achieve high anti-loosening strength, simple structure, and easy manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

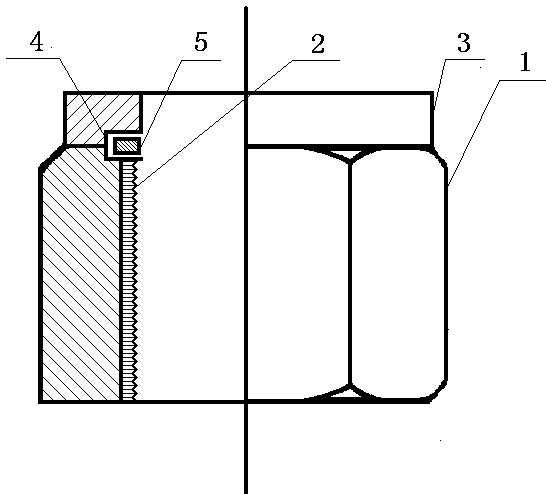

[0013] according to figure 1 As shown, a high-strength lock nut of the present invention includes a nut body 1, an internal thread 2 is arranged in the screw hole of the nut body 1, and an annular ring is arranged on the axial direction of the nut body 1. The transition part 3, the inner diameter of the annular transition part 3 is slightly smaller than the inner diameter of the nut body 1; the joint part of the annular transition part 3 and the nut body 1 in the screw hole is provided with an annular groove 4, so The above-mentioned annular groove 4 is embedded with a nylon ring 5 .

[0014] The high-strength locking nut of the present invention has obvious advantages, namely, simple structure, easy manufacture, low cost, anti-vibration, high anti-loosening strength, safety and reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com