Bolt connecting and fastening device for third-rail train current collectors and slide plates

A technology for connecting fastening and current collectors, applied in the direction of threaded fasteners, bolts, connecting components, etc., can solve problems such as vibration, easy loosening of bolts, separation of slide plates and current collectors, etc., to prevent loosening and avoid The effect of excessive stress concentration and improving the ability of anti-vibration and anti-loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

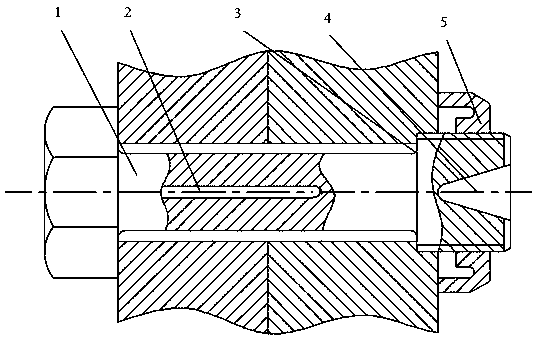

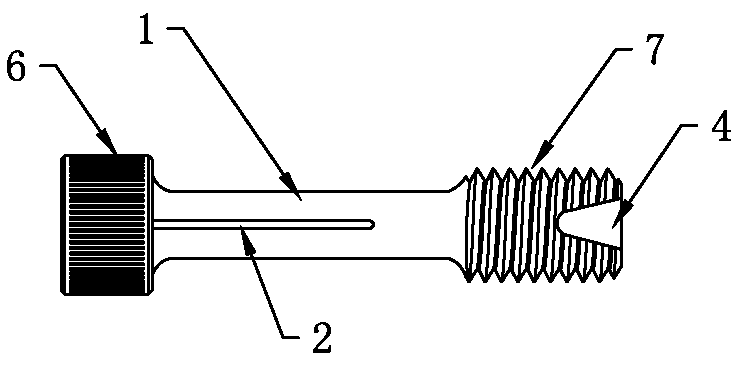

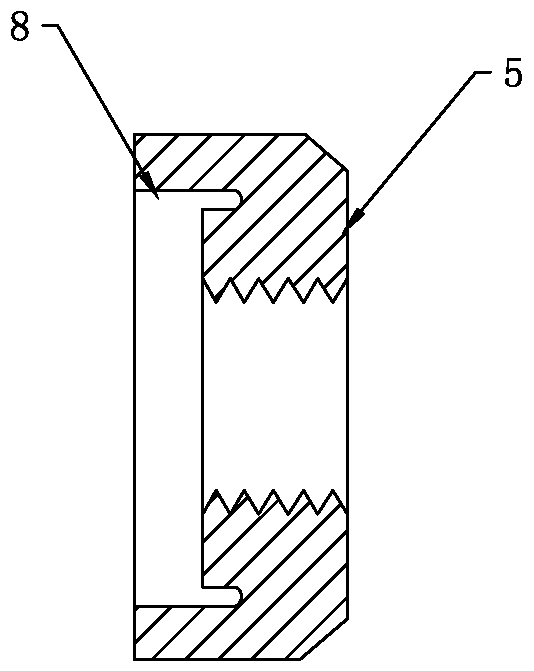

[0019] see Figures 1 to 3 In this embodiment, a connection and fastening device between a train collector and a slide plate includes a bolt and a slide bar, wherein the bolt includes a nut 6, a polished rod 1 and a threaded rod 7, and the diameter of the polished rod 1 in the prior art is usually equal to The thread diameters are the same, although the polished rod 1 has high rigidity, the anti-seismic effect is poor, and the bolts and nuts 5 are very easy to loosen in a high-frequency vibration environment. In this embodiment, the diameter of the polished rod 1 is d0, and the thread diameter of the threaded rod 7 is d1, so that d0=0.8d1, that is, the polished rod 1 is one-fifth smaller than the thread diameter. This proportional relationship is to realize the connection and fastening device The best ratio of shock resistance and rigidity. Simultaneously, transition fillets 3 are provided at the joints between polished rod 1 and nut 6 and threaded rod 7, and the radius of tr...

Embodiment 2

[0022] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the radius of the transition fillet 3 at the connection between the polished rod 1 and the threaded rod 7 is r2, where r2=0.2×p, where p is the pitch of the threaded rod 7 .

Embodiment 3

[0024] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. In this embodiment, the radius of the transition fillet 3 at the connection between the polished rod 1 and the threaded rod 7 is r2, where r2=0.22×p, where p is the pitch of the threaded rod 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com