Battery assembly, electric vehicle and design method

A battery assembly and battery module technology, applied in the field of electric vehicles and design, battery assembly, can solve problems such as failure, low safety performance, liquid cooling plate damage, etc., to delay thermal runaway, reduce weight, and reduce fatigue. the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

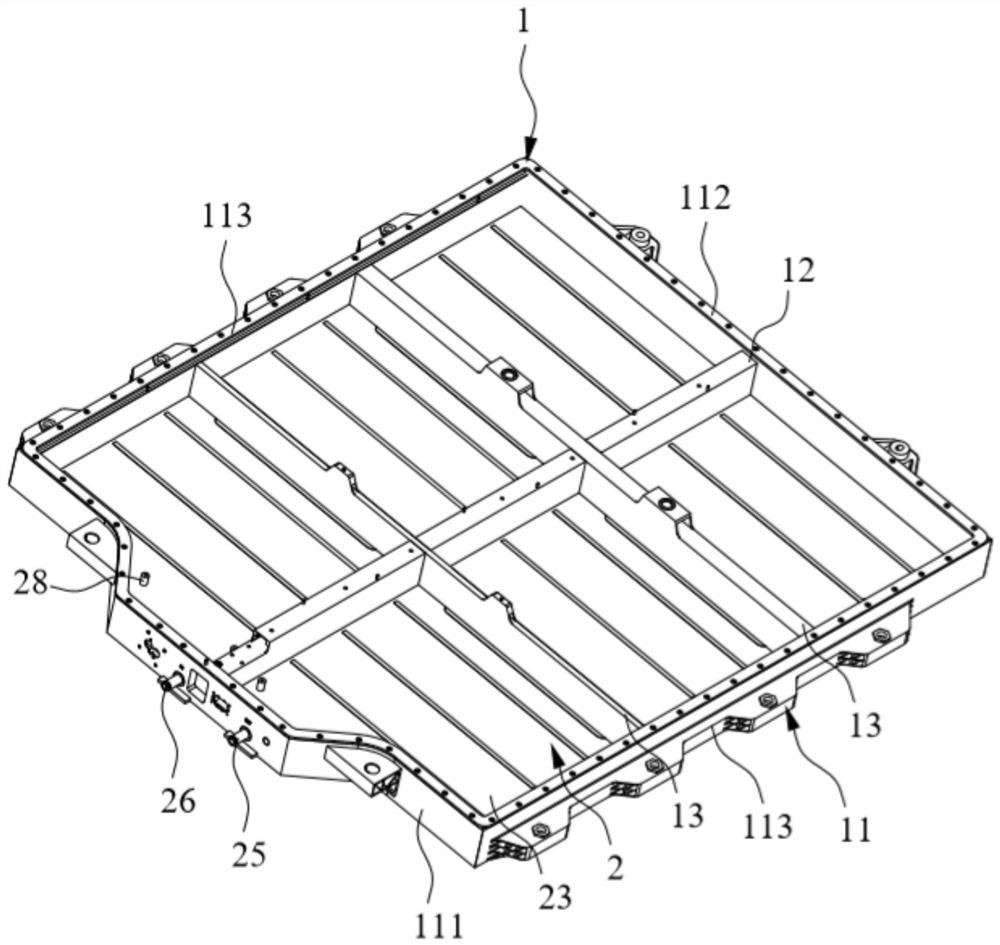

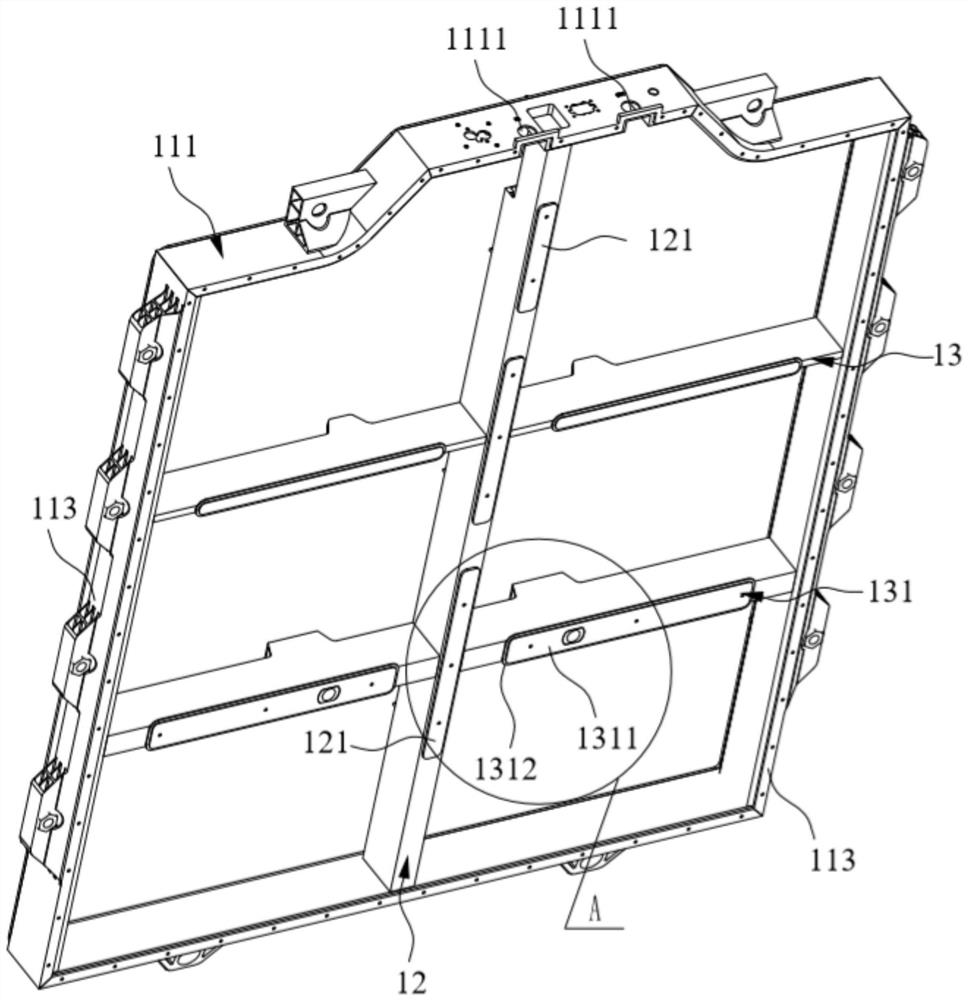

[0049] As shown in Figures 1-7, the embodiment of the present invention provides a battery assembly, comprising a lower case 1 and a liquid cooling plate 2. drop box

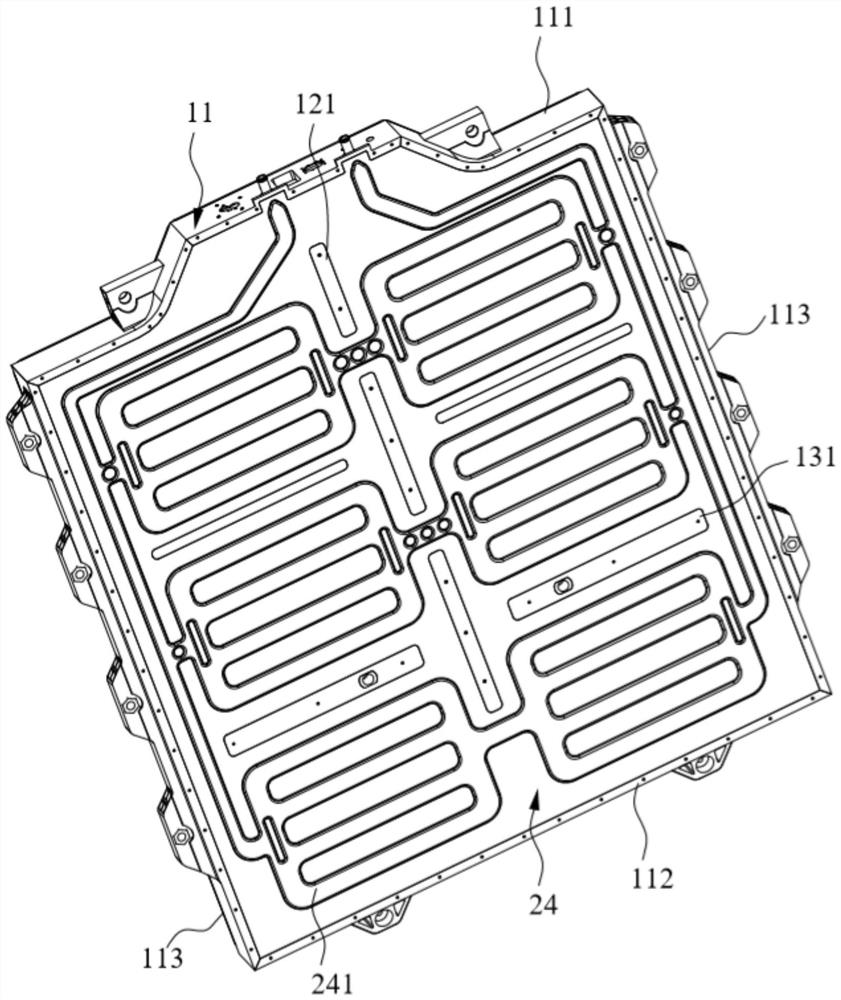

[0051] Further, the liquid cooling plate 2 includes an upper plate 23, a lower plate 24, a water outlet pipe joint 25 and a water inlet pipe joint 26. on board 23

[0054] Further, the liquid cooling plate 2 also includes a plurality of insulating strips 27, a heat conducting structure and a plurality of fixing columns 28. Insulation strip 27 solid

[0055] Further, the flow channel 241 includes three total flow channels 2413 and a spoiler structure. Three total flow channels 2413 are set in parallel,

[0056] Further, the spoiler structure includes a spoiler ring 2415 and a spoiler channel 2416. As shown in Figure 7, the total flow of the three parallel

Embodiment 2

[0058] This embodiment provides an electric vehicle, including the battery assembly in the first embodiment. Electric Vehicle Adoption Example

Embodiment 3

[0062] The general flow channel 2413 designed in parallel can enhance the mechanical reliability of the battery assembly and improve the overall fatigue performance. exist

[0064] The parallel shunt channels 2414 are calculated by the pressure drop of the liquid cooling plate 2, and the number of the shunt channels 2414 in common use is 3-6. Pass

[0066] The turbulence structure is used to adjust the flow distribution of the plurality of total flow channels 2413, and through the turbulence structure, the

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com