Fully-sealed wind power slagging gas-drainage deep well drilling system and method

A deep hole drilling and fully enclosed technology, which is applied in gas discharge, safety devices, earthwork drilling and mining, etc., can solve the problems of gas explosion, the inability of the drill bit to achieve continuous drilling, and difficulty in adapting to frequent replacement of drilling positions. To achieve the effect of avoiding top drill, chip removal channel blockage and drill sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

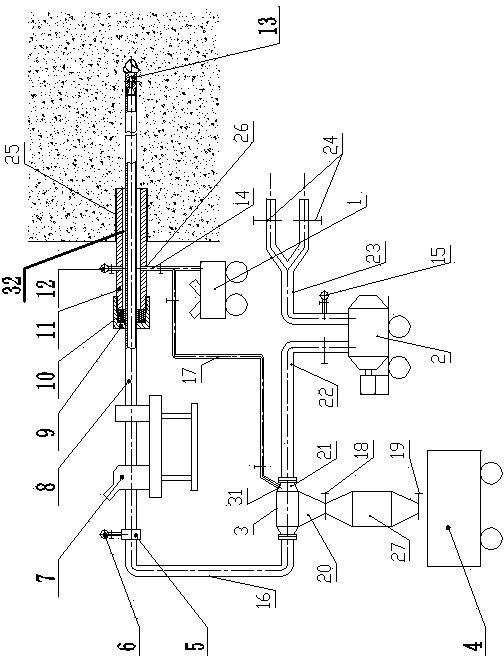

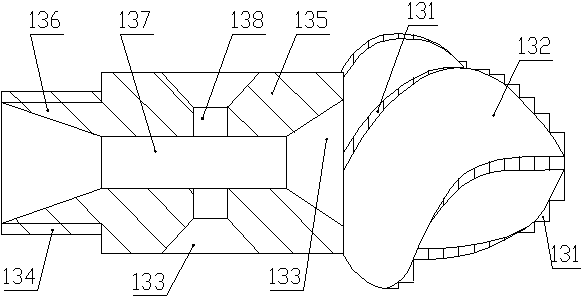

[0028]In the present invention, take the drilling direction as the forward direction.

[0029] Such as figure 1 and figure 2 As shown, the fully enclosed air-powered slagging and gas deep-hole drilling system of the present invention includes a drill pipe 8 with an inner hole, and the drill pipe 8 includes two or more hollow drill pipe sections that are screwed together sequentially; The front end of rod 8 is provided with anti-helical crushing dust-absorbing drill bit 13, and the rear portion of drill rod 8 is connected on the drilling machine 7.

[0030] The drill pipe 8 at the borehole opening is coaxially sleeved with an orifice seal pipe 11, and the orifice seal pipe 11 extends from the borehole to the outside of the borehole, and the drill pipe 8 at the rear end of the aperture seal pipe 11 is provided There is a sealing packing 10 and a sealing gland 9 that compresses the sealing packing 10 between the drill pipe 8 and the orifice sealing pipe 11; an air inlet portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com