Anchoring device adopting spiral slotting clamping piece for prestressed FRP (Fiber Reinforced Polymer) cables

A composite material and anchoring device technology, applied in building reinforcements, structural elements, building components, etc., can solve the problems of uneven deformation, difficult to withdraw anchors, low anchoring efficiency, etc., to achieve uniform deformation, easy processing and use, and anchoring Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

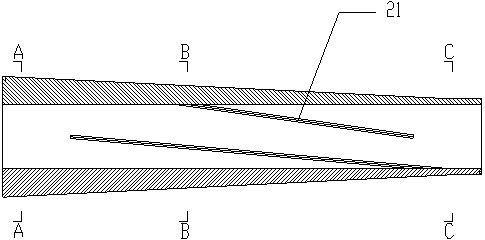

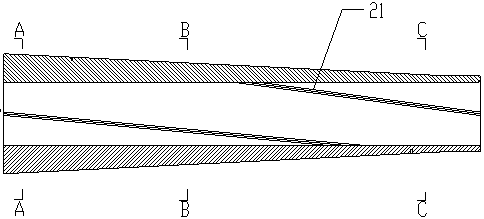

[0033] Example 1: Anchorage of a single fiber reinforced composite cable

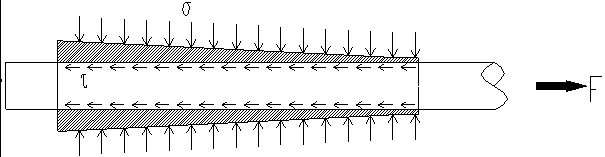

[0034] The anchoring process of a single composite cable of the present invention is as follows: the fiber reinforced composite cable 3 is passed through the structure and the anchor block 1, the composite cable anchor clip 2 is placed on the cable and pushed into the hole of the anchor block 1, Put the auxiliary compression ring on the end of the clip, use the jack to pull the fiber reinforced composite material cable 3, and at the same time push the composite cable anchor clip 2 into the anchor block 1, tighten the compression ring after reaching the required prestress, and unload When the pulling force of the jack is dropped, the fiber-reinforced composite cable 3 retracts and tightens under the prestress, driving the composite cable anchoring clip 2 so that the clip 2 and the anchor block 1 are tightly combined. image 3 It is a schematic diagram of the interaction between the fiber-reinforced compo...

Embodiment 2

[0035] Example 2: Three fiber reinforced composite cables anchored in a rectangular anchor block

[0036] Rectangular anchor blocks such as Figure 6 As shown, the anchoring method of each FRP cable (fiber-reinforced composite material cable) is the same as that described in the above example, and the three anchoring diagrams are as follows Figure 7 shown.

Embodiment 3

[0037] Example 3: Three fiber reinforced composite cables anchored in a ring anchor block

[0038] Ring anchor blocks such as Figure 8 As shown, the anchoring method of each FRP cable is the same as that described in the above example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com