Fish scale and fish skin collagen active peptide manufacturing technology

A collagen active peptide and production process technology, applied in the biological field, can solve problems such as low product added value, low production capacity, and environmental pollution, and achieve the effects of low average relative molecular weight, low cost, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

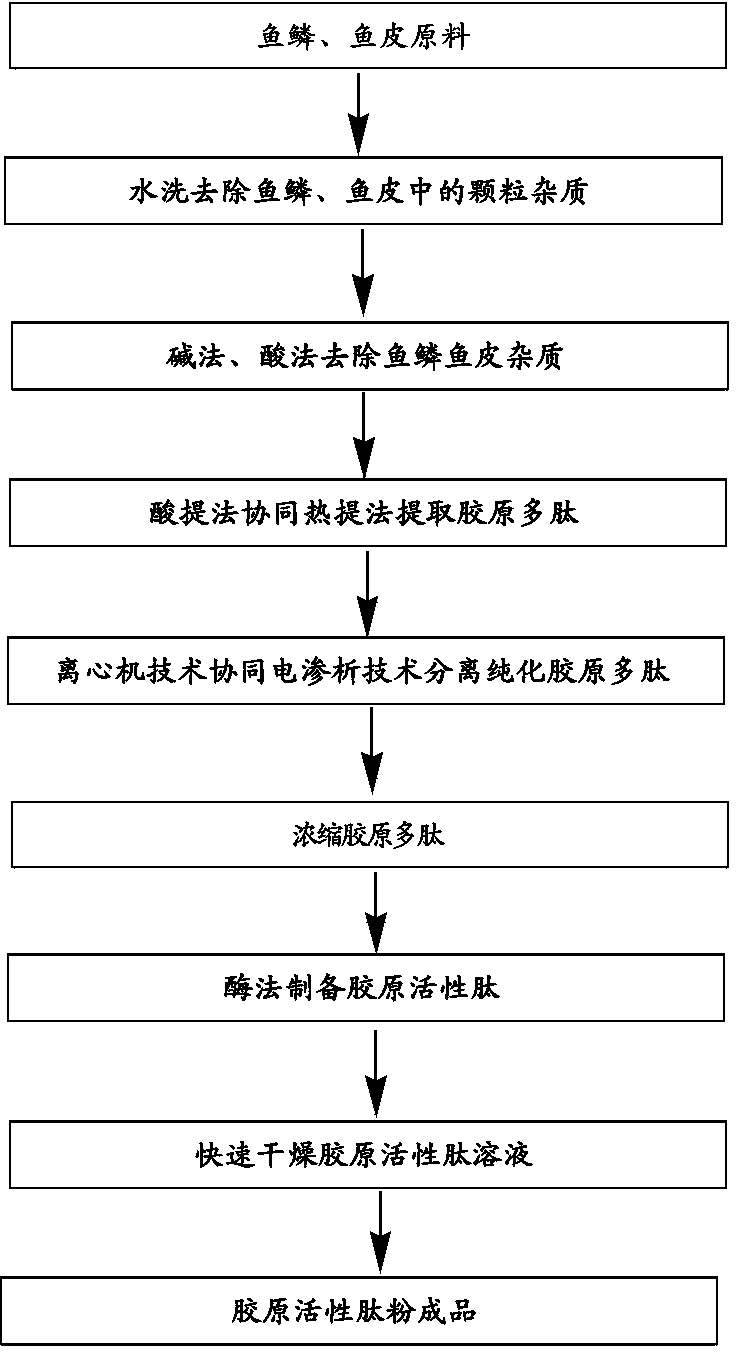

Method used

Image

Examples

Embodiment 1

[0041] 1. Fish scales are used as raw materials. The selected fish scales can be marine fish scales or freshwater fish scales. Get 100kg of fish scales and put it into a washing machine, add 1500kg of water, wash 3 times, and remove particle impurities. Put the washed fish scales into a washing machine, add 500 kg of sodium bicarbonate solution with a concentration of 1% by mass, stir for 8 hours, and wash with water. Add 500kg volume percent concentration again and be 0.01‰ sulfuric acid solution, stir for 9 hours, wash with water, remove sticky substance, fat and other impurities on the fish scale surface.

[0042] 2. Put the washed fish scales in the reaction kettle, add 500kg of water, add sulfuric acid to adjust the pH value and control the pH of the reaction system to 4, the reaction temperature is 100°C, react for 5 hours, and finish the reaction to obtain collagen peptides, extract the product The rate is 96%.

[0043] 3. Using an 8000rpm centrifuge to separate the a...

Embodiment 2

[0048] 1. Fish scales are used as raw materials. The selected fish scales can be marine fish scales or freshwater fish scales. Get 500kg of fish scales and put it into the washing machine, add 5000kg of water, wash 3 times, and remove particle impurities. Put the washed fish scales into a washing machine, add 5000 kg of 1% sodium hydroxide solution by mass percentage, stir for 11 hours, and wash with water. Add 5000kg volume percent concentration and be 0.05‰ sulfuric acid solution, stir for 10 hours, wash with water, remove sticky matter, fat and other impurities on the fish scale surface.

[0049] 2. Put the cleaned fish scales in the reaction kettle, add 10000kg of water, add sulfuric acid to adjust the pH value and control the pH of the reaction system to 2, the reaction temperature is 90°C, react for 6 hours, and end the reaction to obtain collagen peptides, extract the product The rate is 98%.

[0050]3. Using a 4000rpm centrifuge to separate the above-mentioned collag...

Embodiment 3

[0055] 1. Fish scales are used as raw materials. The selected fish scales can be marine fish scales or freshwater fish scales. Get 1000kg of fish scales and put them into the cleaning machine, add 10000kg of water, wash 3 times, and get rid of particle impurities. Put the washed fish scales into a washing machine, add 30000 kg of sodium bicarbonate solution with a concentration of 3% by mass, stir for 8 hours, and wash with water. Add 30000kg volume percent concentration and be 0.1‰ sulfuric acid solution, stir for 9 hours, wash with water, remove sticky matter, fat and other impurities on the fish scale surface.

[0056] 2. Put the washed fish scales in the reaction kettle, add 10000kg of water, add sulfuric acid to adjust the pH value and control the pH of the reaction system to 2, the reaction temperature is 80°C, react for 7 hours, and end the reaction to obtain collagen peptides, extract the product The rate is 98%.

[0057] 3. Using a 4000rpm centrifuge to separate the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative molecular weight | aaaaa | aaaaa |

| Relative molecular weight | aaaaa | aaaaa |

| Average relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com