Single-component deamination-type high-conductivity silicone rubber and preparation method thereof

A deaminated, highly conductive technology, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of difficult, waste, and uneven mixing of adhesive conductive silicone rubber. To achieve the effect of simple preparation, good bonding, and simple curing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

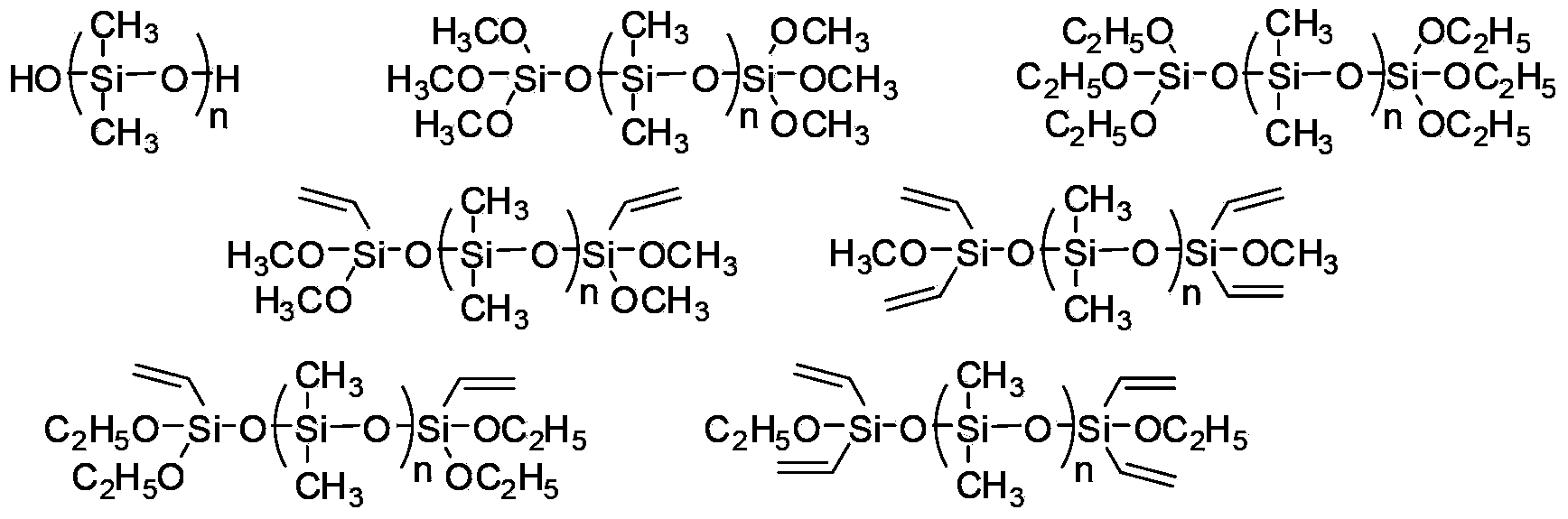

Method used

Image

Examples

Embodiment 1

[0045] The formula of one-component deaminated high-conductivity silicone rubber, calculated in parts by weight, includes the following components:

[0046] Conductive adhesive intermediate:

[0047] 10 parts of hydroxyl terminated polydimethylsiloxane

[0048] 0.3 parts of simethicone

[0049] 12 parts of nano calcium carbonate

[0050] 0.03 parts of silica

[0051] 0.02 parts of hexamethyldisilazane

[0052] One-component deaminated high-conductivity silicone rubber:

[0053] 21 parts of conductive intermediate

[0054] 68 parts silver-plated nickel powder

[0055] 0.08 parts of methyltricyclohexylaminosilane

[0056] 0.01 parts of γ-aminopropyltriethoxysilane

[0057] 0.01 part dibutyltin dilaurate

[0058] 10.9 parts petroleum ether

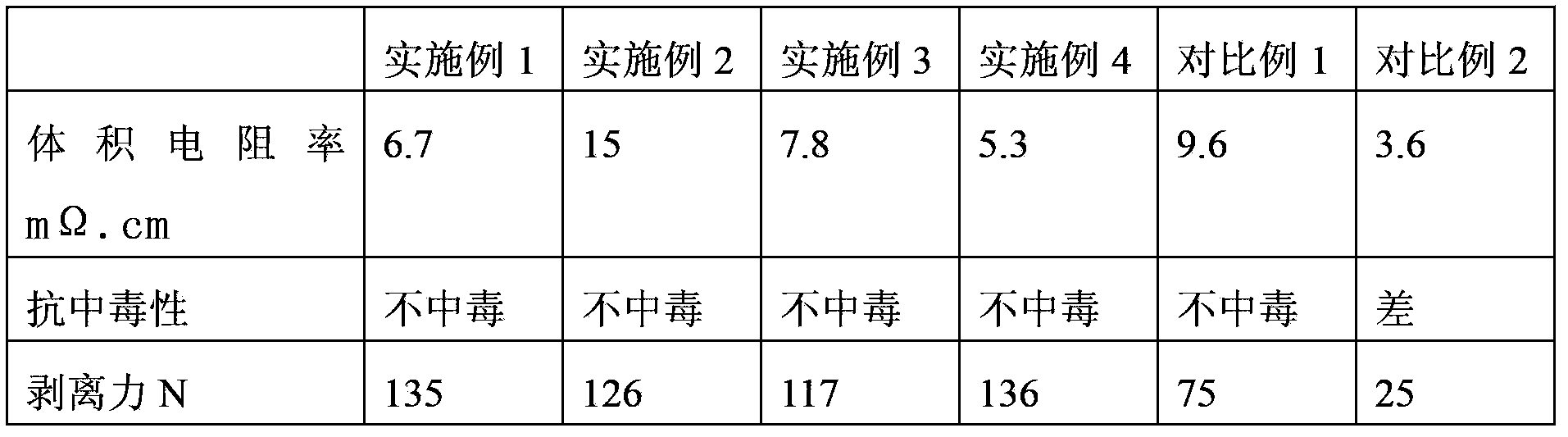

[0059] A single-component deaminated high-conductivity silicone rubber with a tensile strength greater than 2.0MPa, an elongation greater than 50%, a Shore A hardness of 71, and a volume resistivity of 6.7mΩ.cm was obtained.

Embodiment 2

[0061] The formula of one-component deaminated high-conductivity silicone rubber, calculated in parts by weight, includes the following components:

[0062] Conductive adhesive intermediate:

[0063] 15 parts of hydroxyl terminated polydimethylsiloxane

[0064] 0.1 parts of octamethylcyclotetrasiloxane

[0065] 10 parts microsilica

[0066] 0.03 parts of silica

[0067] 0.02 parts of vinyltrimethoxysilane

[0068] One-component deaminated high-conductivity silicone rubber:

[0069] 32 parts of conductive intermediate

[0070] 54 parts nickel-coated graphite

[0071]0.08 parts of methyltris(methylpropyl)aminosilane

[0072] 0.01 parts of γ-aminopropyltriethoxysilane

[0073] 0.01 part dibutyltin dilaurate

[0074] 13.9 parts of toluene

[0075] A single-component deaminated high-conductivity silicone rubber with a tensile strength greater than 1.5MPa, an elongation greater than 150%, a Shore A hardness of 60, and a volume resistivity of 15mΩ.cm was obtained.

Embodiment 3

[0077] The formula of one-component deaminated high-conductivity silicone rubber, calculated in parts by weight, includes the following components:

[0078] Conductive adhesive intermediate:

[0079] 20 parts trimethoxy-terminated polydimethylsiloxane

[0080] 1 part simethicone

[0081] 18 parts of nano calcium carbonate

[0082] 0.8 parts of silica

[0083] 0.02 parts of hexamethyldisilazane

[0084] One-component deaminated high-conductivity silicone rubber:

[0085] 20 parts conductive intermediate

[0086] 65 parts silver-plated copper powder

[0087] 0.1 parts of methyltricyclohexylaminosilane

[0088] 0.01 parts of γ-aminopropyltriethoxysilane

[0089] 0.01 part tin acetate

[0090] 14.88 parts xylene

[0091] A one-component deaminated high-conductivity silicone rubber with a tensile strength greater than 1.8MPa, an elongation greater than 70%, a Shore A hardness of 68, and a volume resistivity of 7.8mΩ.cm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com