Micropatterned hydrogel coating, its preparation method and use

A micropatterning and hydrogel technology, applied in biochemical equipment and methods, biochemical instruments, nervous system cells, etc., can solve the problems of difficult comparison of cell culture results, etc., and achieve easy-to-obtain raw materials, simple preparation methods, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The preparation steps of the hydrogel solution: adding the raw materials used to prepare the micropatterned hydrogel coating as a solute into distilled water at 70°C to 90°C, fully stirring and dissolving to form water with a weight percentage of 1 wt% to 10 wt% For the gel solution, keep the temperature of the hydrogel solution within the range of 70°C to 90°C.

[0043] Molding step of the hydrogel coating: select a suitable carrier for carrying the micropatterned hydrogel coating, and evenly spread the prepared hydrogel solution at a temperature of 70°C to 90°C on the carrier Lower the temperature to 40° C. to 60° C., and when the hydrogel solution forms a hydrogel viscous colloid, press the mold on the hydrogel viscous colloid and print the obtained dot matrix pattern. The raw material includes at least one of carrageenan, locust bean gum, gum arabic, xanthan gum, algin, fucoidan, xylan, agarose, mannan, galactomannan, and glucomannan kind.

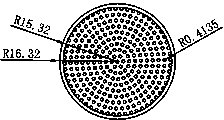

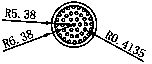

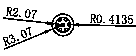

[0044] The mold is a s...

Embodiment 1

[0048] Preparation of 6-well cell culture plates with micropatterned hydrogel coatings included.

[0049] A standard 6-well flat-bottomed cell culture plate made of ordinary polystyrene, used as a carrier for hydrogel coating preparation after sterilization. First, several powdered solids such as gum arabic, xanthan gum, agarose, and glucomannan were mixed at a mass ratio of 2:1:6:1, and added to distilled water at 90 °C to make the solute mass fraction about 4 wt%. Prepare the hydrogel solution, fully stir to dissolve and keep the hydrogel solution at 90°C. Then, take the hydrogel solution in the above incubation and add it to each well of the prepared 6-well plate. The amount added to each well is about 900 μl. The amount added to each well depends on the volume of a single well of the culture plate or the culture dish. The larger the volume, the amount added should be increased accordingly. For example, the amount added to each well of a 6-well plate should be greater than...

Embodiment 2

[0051] Preparation of Petri dishes with micropatterned hydrogel coatings included.

[0052] A 35 mm standard petri dish made of ordinary polyethylene was used as a carrier for micropatterned hydrogel coating preparation after sterilization. A 90°C hydrogel solution was prepared as described in Example 1, and about 800 μl of the 90°C hydrogel solution was added to a petri dish. The molding curing and demoulding steps of the hydrogel coating are similar to Example 1, the difference is that a mechanical pressurizing device is used in this example to connect the mold of the round-bottom stamp for automatic pressurization, such as Figure 5a and 5b . The device can greatly improve production efficiency and reduce the influence of human factors, Figure 5c Shown is a formed 35 mm cell culture dish containing a micropatterned hydrogel coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com