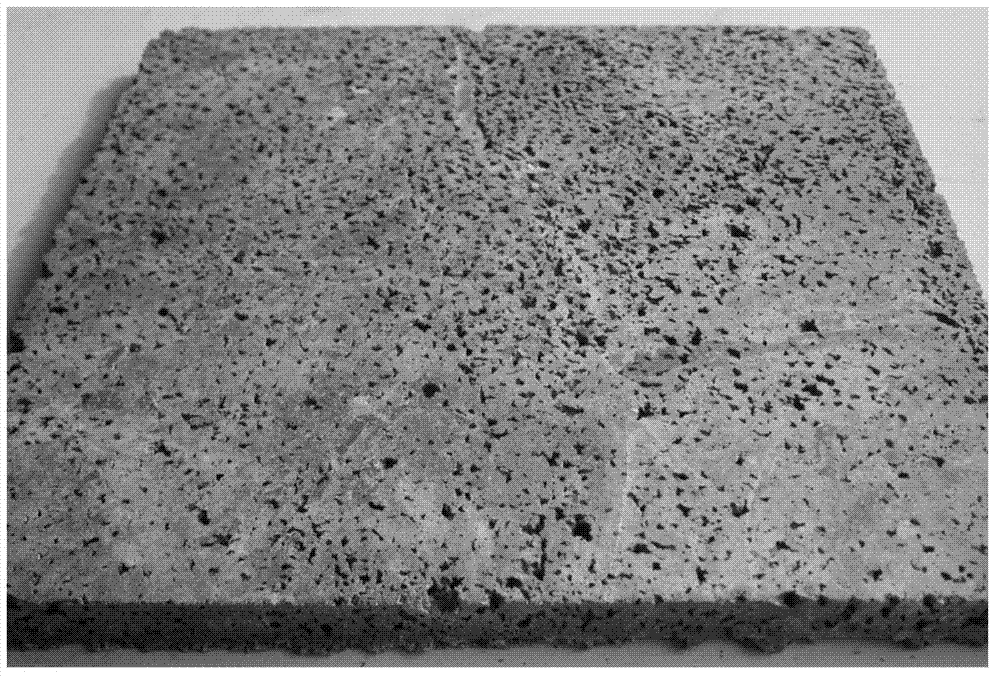

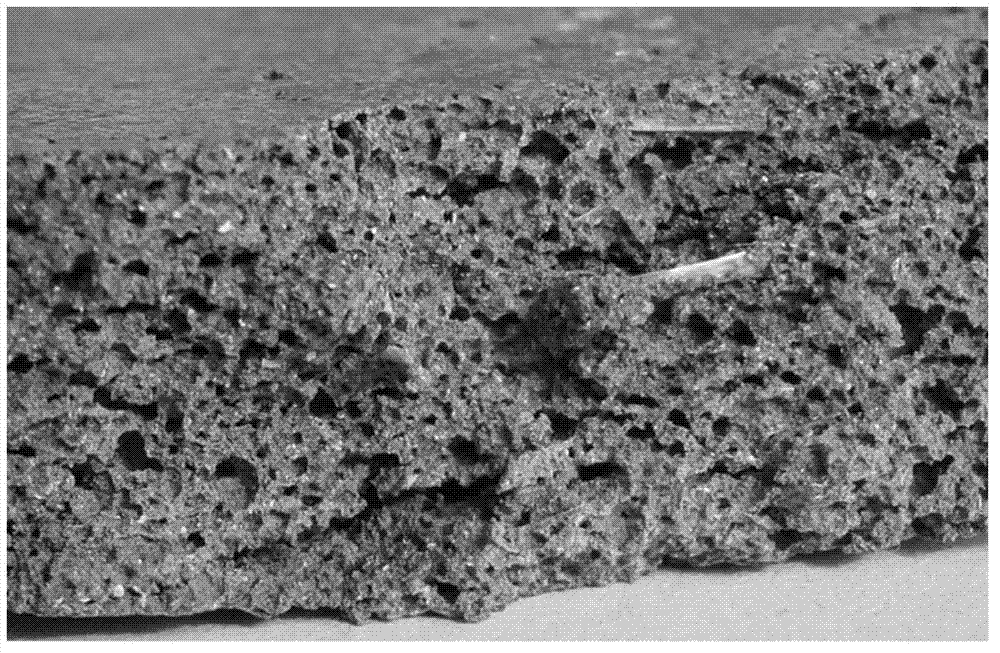

Preparing method for high-strength light multihole construction waste composite

A construction waste and composite material technology, applied in the field of construction waste reuse, can solve problems such as less than 5%, and achieve the effects of good water resistance, high surface hardness and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

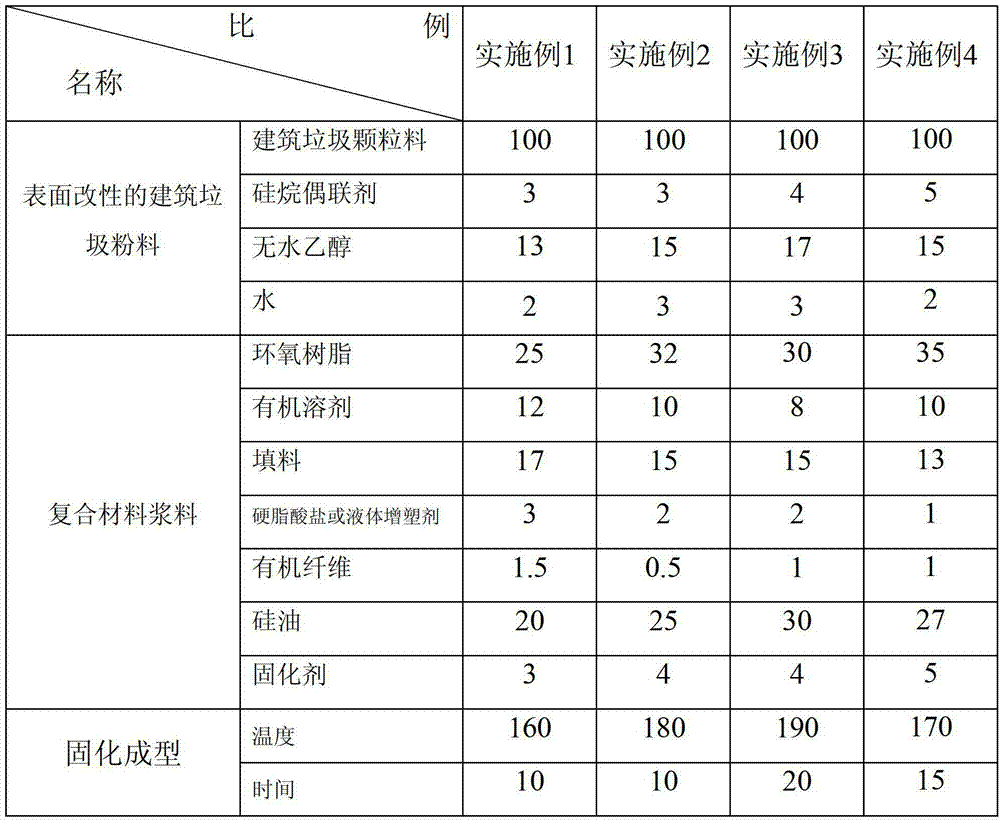

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] 1. Materials, reagents and equipment used in the invention

[0033] 1) The materials and reagents used are as follows:

[0034] Construction waste powder, 200 mesh, construction demolition site;

[0035] Silane coupling agent (KH-550, etc.), chemically pure, Shanghai Yaohua Chemical Factory;

[0036] Anhydrous ethanol (such as organic solvents), chemically pure, Xi'an Miura Fine Chemical Factory;

[0037] Epoxy resin, E-44, Xi'an Keda Adhesive Co., Ltd.;

[0038] Phenolic resin powder, PF2123, Hebei Hongye Chemical Co., Ltd.;

[0039] Acetone (such as organic solvents), chemically pure, Xi'an Miura Fine Chemical Factory;

[0040] Silicone oil, chemically pure, Xi'an Miura Fine Chemical Factory;

[0041] Stearate or liquid plasticizer, chemically pure, Tianjin North Tianyi Chemical Reagent Factory;

[0042] Glass fiber (fiber), 20mm, Langfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com