Production line for preparing lime with marble thick liquid and powder

A marble and production line technology, applied in the field of marble slurry and powder preparation lime production line, can solve problems such as environmental pollution, and achieve the effects of short process, scientific structure design and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

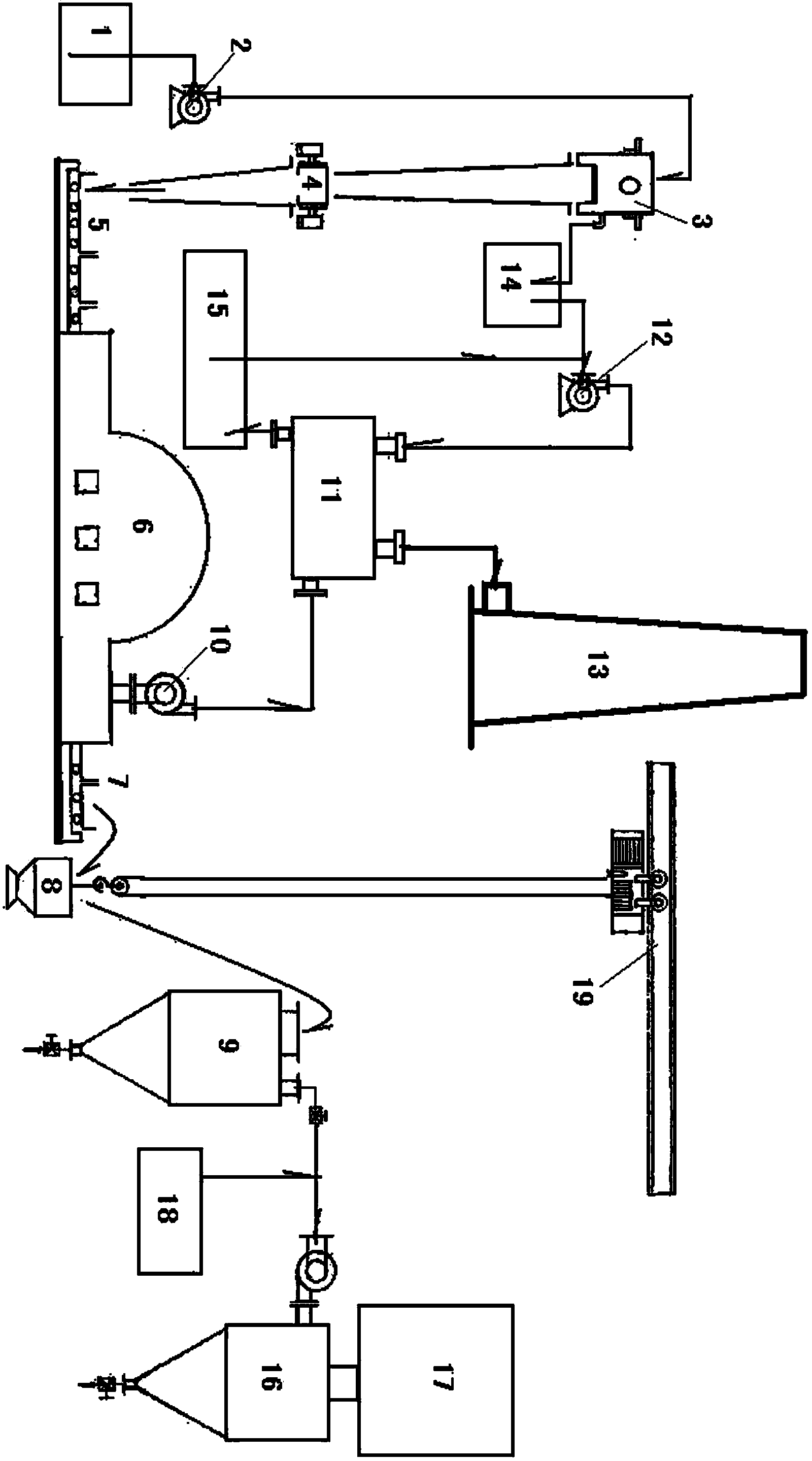

[0011] Such as figure 1 Shown, marble slurry of the present invention, powder prepare lime production line, its raw material pond (1), feed pump (2), press filter (3), feeding machine (4), hopper (5), roasting furnace ( 6), bucket (8), high-level storage bin (9), exhaust fan (10), water spray dedusting room (11), water pump (12), chimney (13), filtrate storage tank (14), Equipment and parts such as water sedimentation clarifier (15), cyclone separator (16), bag filter (17), dust collection system (18) can be obtained by adopting materials and manufacturing methods of the prior art.

[0012] Such as figure 1 As shown, the lime production line prepared from marble pulp and powder of the present invention can also be referred to as a lime production equipment; it consists of a material preparation system, a firing system, and an environmental protection system; the environmental protection system includes water circulation equipment and suspended particle collection equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com