Buckling process for disposable absorbent article fixed patches

An absorbent and disposable technology, which is applied in the field of fastening and fastening of disposable absorbent articles, can solve problems such as folding, packaging obstruction, failure to fasten, and failure to fasten, so as to improve stability and reduce adverse conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0024] refer to Figure 3 to Figure 7 , the present embodiment provides a diaper waist sticker fastening process, which is characterized in that it includes the following steps:

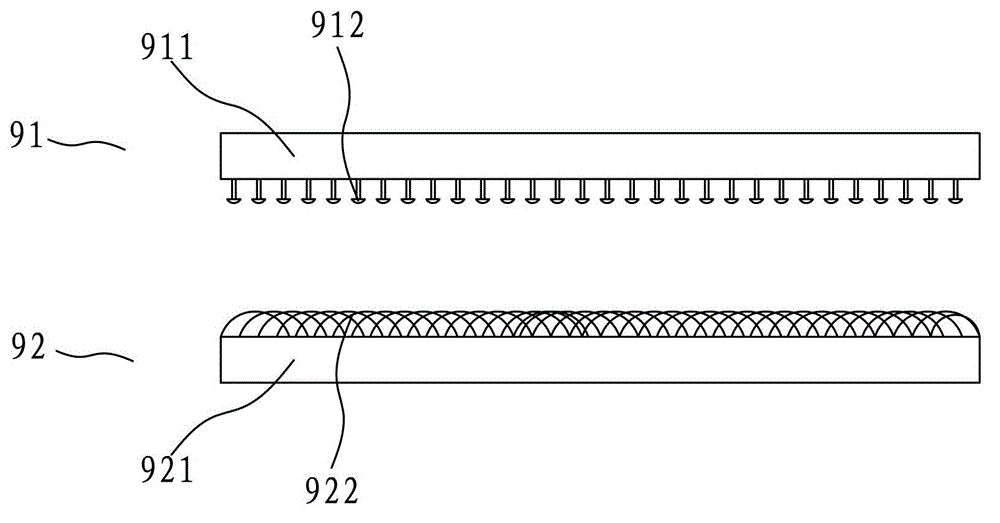

[0025] The first step is to fold up the waist stickers of the finished diapers, and then use the pressure plate to press down, so that the buttons of the two pairs of waist stickers that are opposite to each other fit the plush surface;

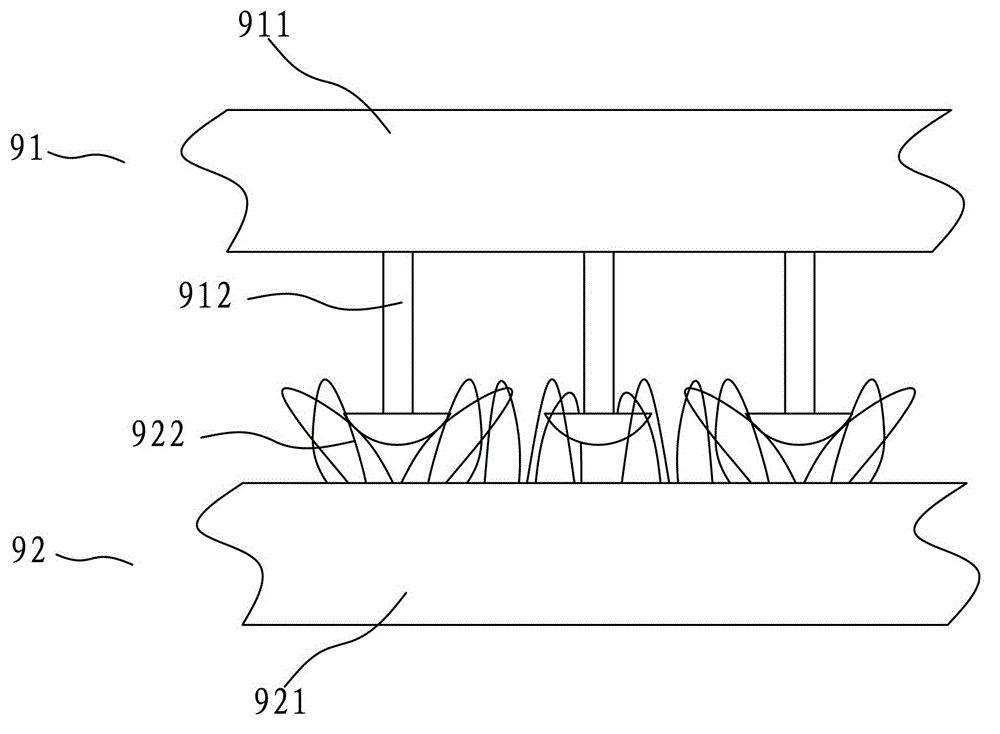

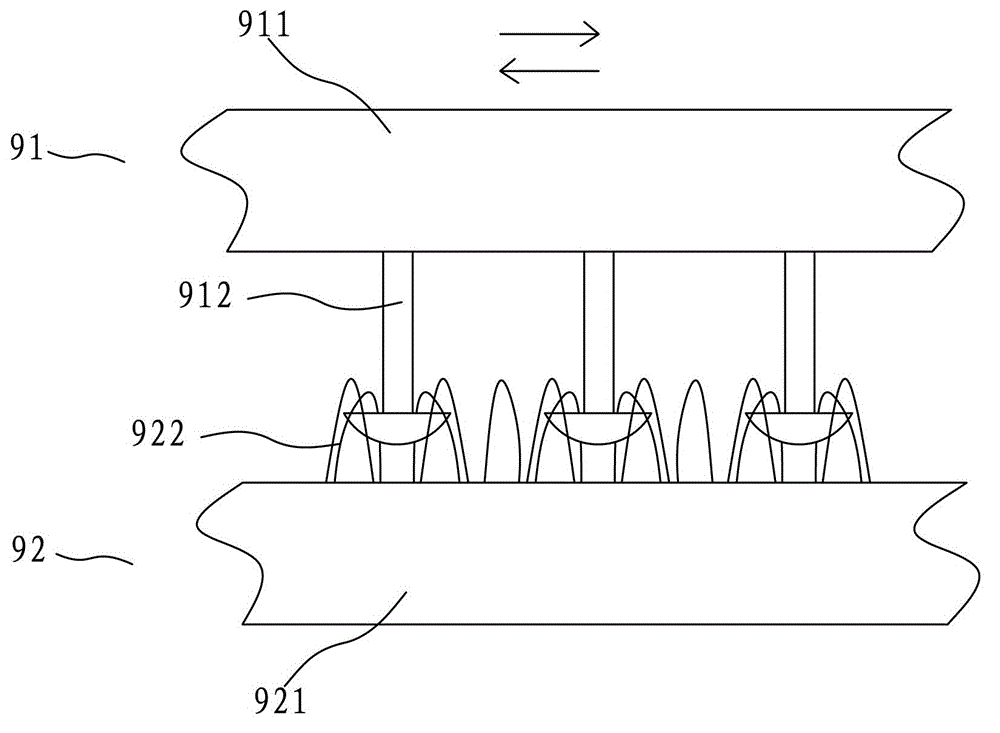

[0026] The second step is to input the diapers with the waist stickers into the rubbing device, and the rubbing device conveys the diapers. When the waist stickers of the diapers are located in the upper and lower rollers of the rubbing device, the rubbing movement of the rubbing device makes the The upper and lower sides of each pair of waist stickers of the diaper produce a relative dislocation movement, that is, each button body and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com