Method for preparing uranium adsorption material with intercalation structure by use of oil shale ash as raw material

A technology for oil shale ash and adsorption materials, which is applied in chemical instruments and methods, removal of solid waste, alkali metal oxides/hydroxides, etc. , the problem of high production cost, to achieve the effect of promoting healthy development, reducing production cost, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

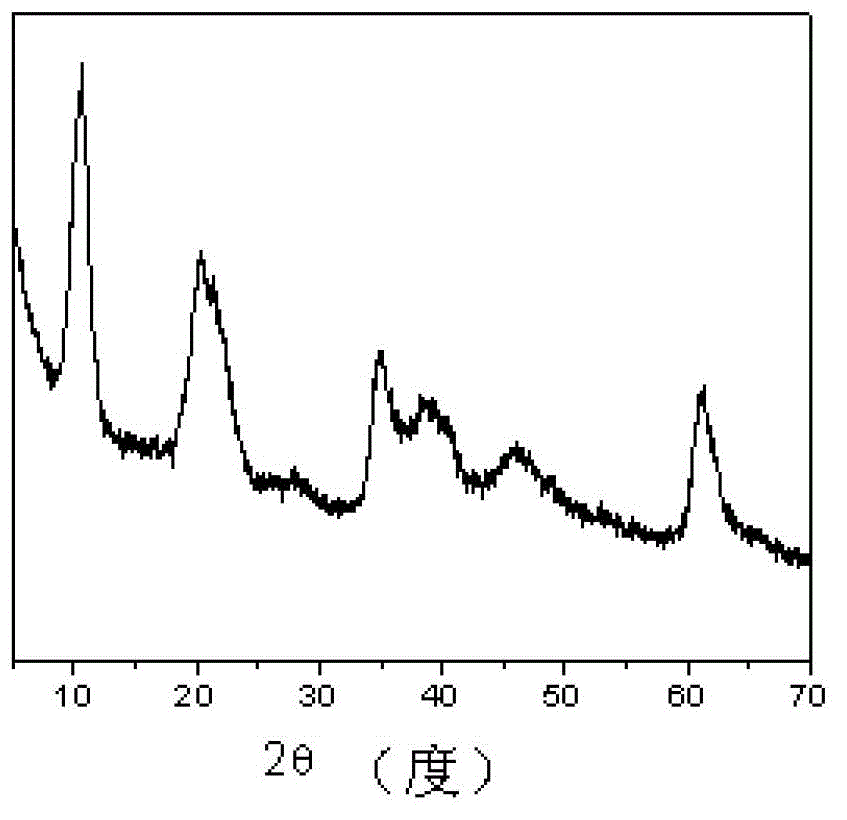

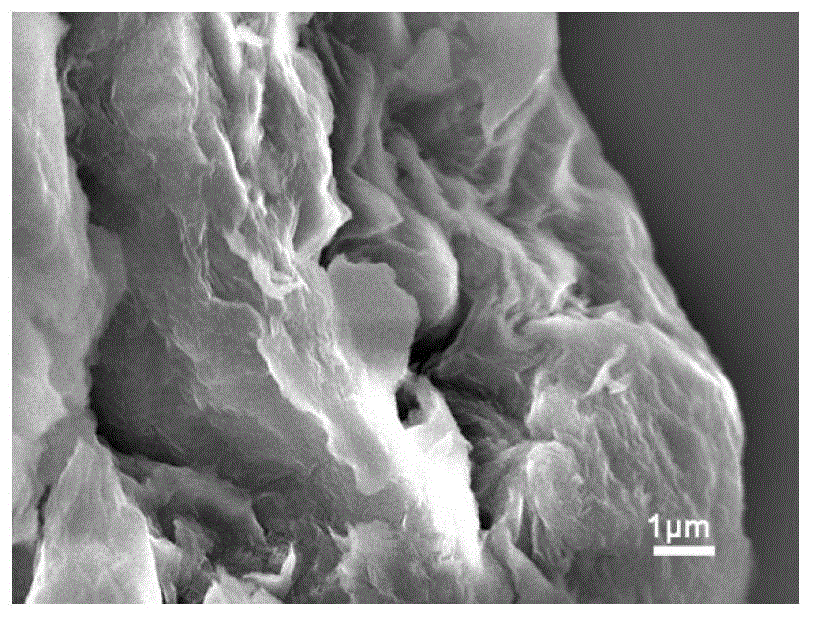

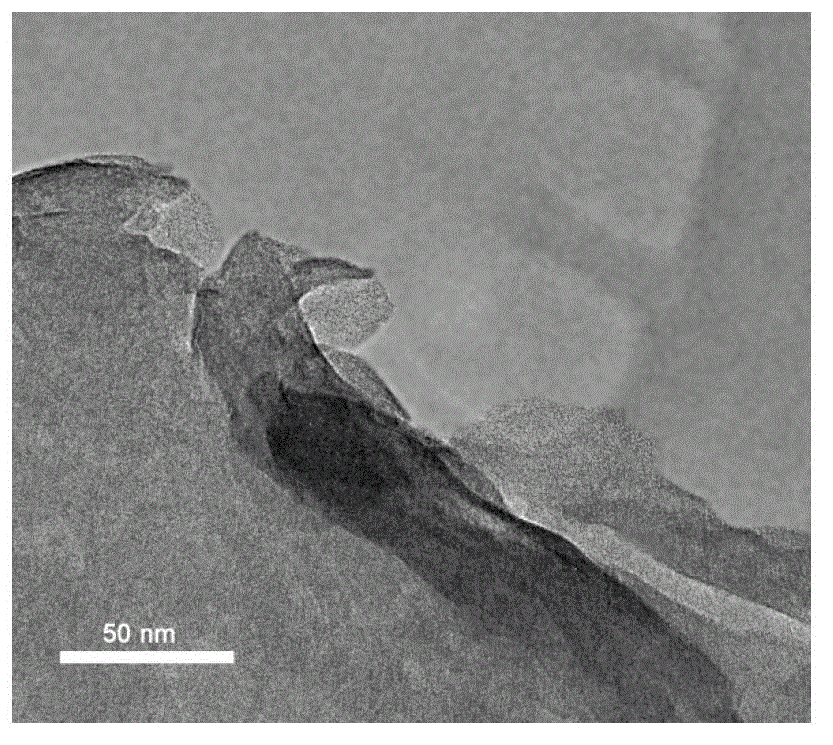

[0028] (1) Crush and grind oil shale ash to 100 mesh, take 10g and add 4-6g NaCl, calcinate for 3-5h at 1000-1400K, air-dry, 20-200ml 30% H 2 SO 4 , heated to 353K to extract metal ions, 3-10h, separate the extract and residue, extract Al 3+ , Fe 3+ , Mg 2+ 、Ti 4+ , Ca 2+ and other metal ions;

[0029] (2) Add Mg(NO 3 ) 2Adjust the ratio of the total moles of trivalent and tetravalent metal ions to the total moles of divalent metal ions in the solution to 1:5-1:2, adjust the pH of the solution with NaOH=7-12, and stir at 353K for 600min;

[0030] (3) The intercalation material is obtained by filtering and drying;

[0031] (4) The filtrate can be recrystallized until the by-product Na 2 SO 4 ;

[0032] (5) Under the condition of pH=4 and 318K, the uranium adsorption capacity is 105mg / g.

Embodiment 2

[0034] The preparation method of the uranium adsorption material in Example 2 is basically the same as that in Example 1, except that in step (1), the oil shale slag is pulverized and ground to 100 mesh, and 10 g is added with 5 g of NaCl, and calcined for 5 h under the condition of 1223 K, Air-dried, 200ml 30%H 2 SO 4 , heated to 353K to extract metal ions, vigorously stirred for 8h, and the leaching solution and residue were separated; in step (5), under pH=4, 318K, the uranium adsorption capacity was 113mg / g.

Embodiment 3

[0036] The preparation method of the uranium adsorption material in Example 3 is basically the same as that in Example 2, with the difference that: step (2) adds Mg(NO) to the leaching solution 3 ) 2 Adjust the ratio of the total moles of trivalent and tetravalent metal ions to the total moles of divalent metal ions in the solution to be 1:2, adjust the pH of the solution with NaOH=11, and stir at 353K for 600 min; step (5) at pH=4, Under the condition of 318K, the uranium adsorption capacity is 168mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com