Method for machining honeycomb-shaped lead guider

A technology of lead guide and processing method, applied in the direction of weapon type, pyrotechnics, offensive equipment, etc., can solve the problems of poor threading, damage, troublesome and time-consuming drilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

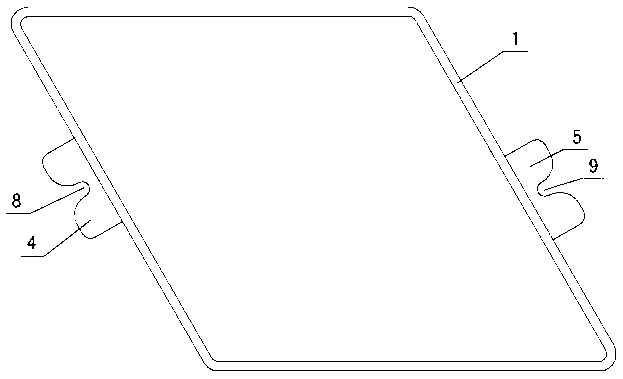

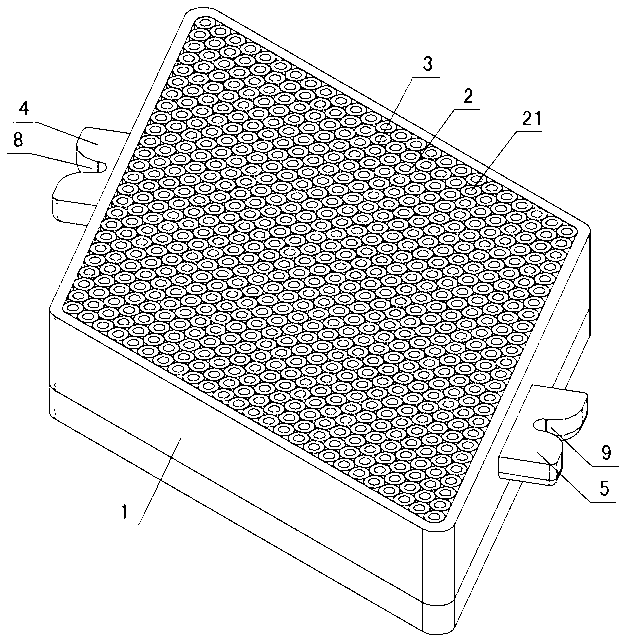

[0023] The invention relates to a processing method of a honeycomb lead wire guide, such as figure 1 — Figure 8 As shown, it is characterized in that it includes a pipe 2, an adhesive layer 3 and an outer frame 1, and the processing steps are:

[0024] ①, the processing of the pipe, take the plastic raw material, adopt the injection molding machine to inject the plastic raw material into a pipe 2, the inner hole of the pipe is a large tapered hole 21 at the other end (such as Figure 5 shown);

[0025] ②, the processing of the outer frame, take the plastic raw material, and use the injection molding machine to inject the plastic raw material into the outer frame 1 (such as figure 2 shown);

[0026] ③. Arranging the tubes, take a diamond-shaped assembly mold, which is composed of a left baffle 12, a right baffle 13, a lower baffle 14, and a bottom plate 15. There is a calibration line 16 on the bottom plate (such as Figure 7 As shown), arrange the pipes 2 one by one into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com