Shear wall water stop method for detachable butt screw

A technology for connecting screws and shear walls, applied in the direction of walls, building components, building insulation materials, etc., can solve the problems of increasing construction costs and increasing the amount of steel used, and achieve the effect of saving steel, reducing construction costs and omitting installation procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

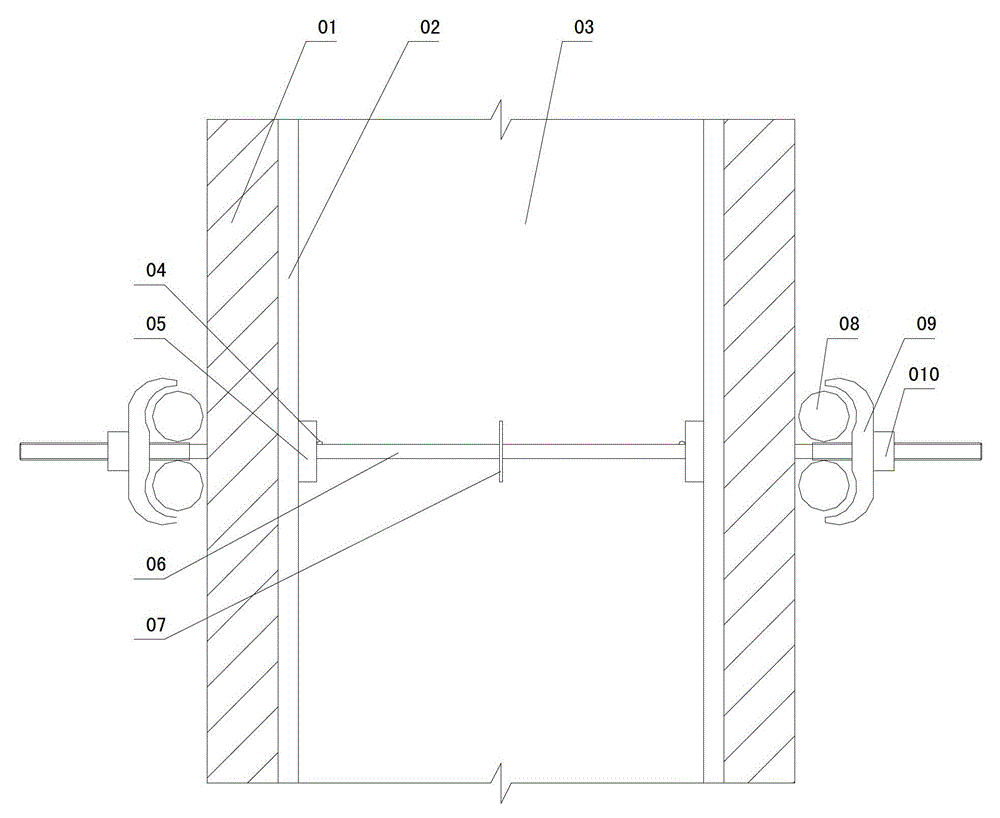

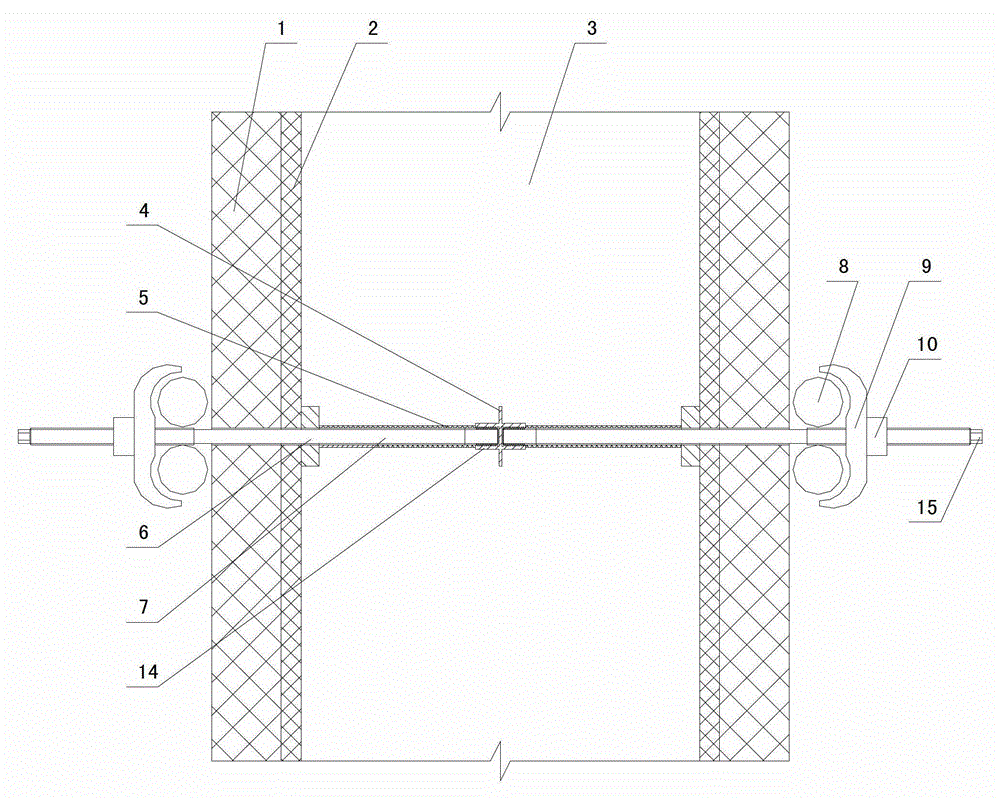

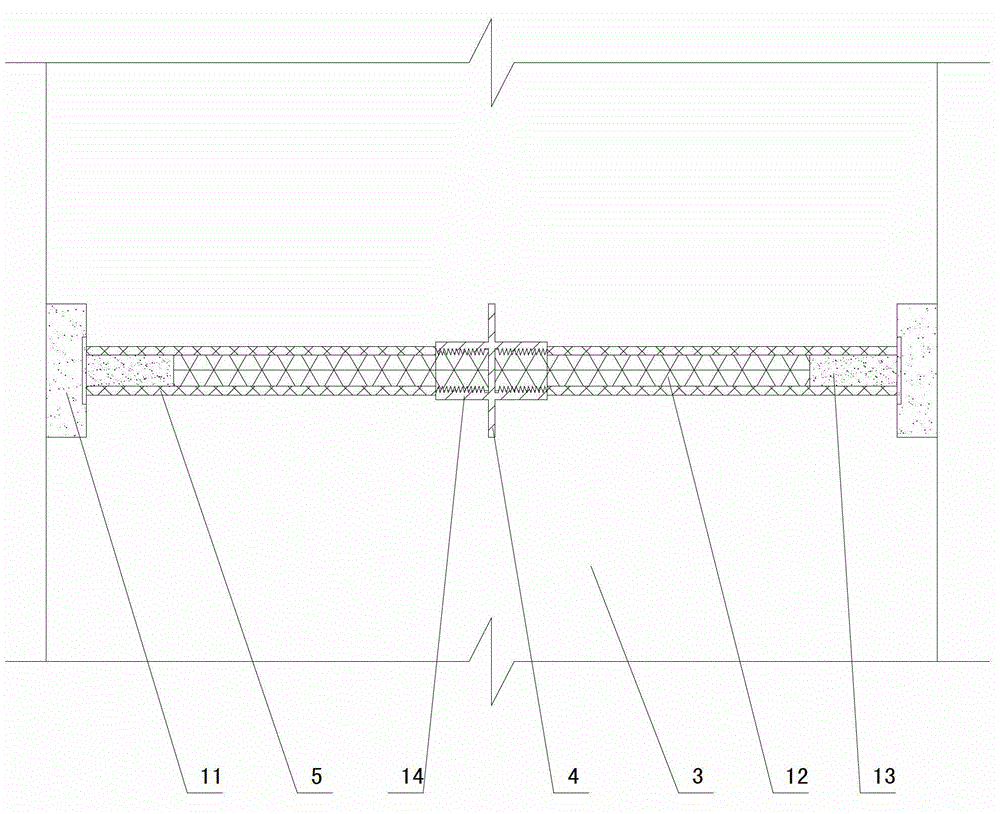

[0039] Combine figure 2 with image 3 The shown schematic diagram of the structure of the detachable butt screw in the shear wall water-stop method of the detachable butt screw of the present invention shows that the installation method of the water-stop steel plate in the shear wall of the present invention includes the following steps:

[0040] 1) Screw one ends of the two butt screws 7 to the sleeves 14 fixed on both ends of the water-stop steel plate 4 respectively. In this embodiment, the two sleeves 14 and the water-stop steel plate 4 are integrally processed , Each sleeve 14 is provided with internal threads that are screwed with the butt screw head; and two iron gaskets 6 coated with a release agent are prepared, and each iron gasket 6 is provided with a butt screw 7 Through holes for sockets;

[0041] 2) Cut two sections of PVC pipe 5 of equa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com