Revolving cup spinning twisting process

A technology of rotor spinning and crafting, which is applied to spinning machines, open-end spinning machines, and continuous winding spinning machines, etc. It can solve the problems of large steam consumption, high cost of equipment transformation, and shortened service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] For the convenience of description, this embodiment provides a manufacturing process of cooked bars.

[0048] 1. Use a forklift to cross-stack the cotton bales in proportion to the cotton path of the plucking machine, and leave a return position in the center of the cotton bales. The average length of viscose staple fiber 1.2D is 32mm, the length deviation rate is ±0.3%, the rate of ultra-long fiber is 0.1%, the double-length fiber is 0.5mg / 100g, the defect is 2.1mg / 100g, and the dosage is 35%; the length of viscose staple fiber is 1.5D The average is 32mm, the length deviation rate is ±0.3%, the ultra-long fiber rate is 0.1%, the double-length fiber is 0.5mg / 100g, the defect is 2.1mg / 100g, and the dosage is 65%.

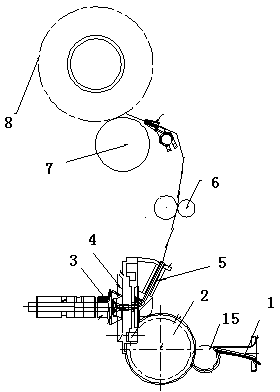

[0049] 2. The catching machine grabs the cotton bundle (block), and adds a roller with reverse claws on both sides of the cotton grabbing arm, such as figure 1 It makes the shape of the cotton bundle grabbed by the plucking machine into a spherical shape, wh...

Embodiment 2

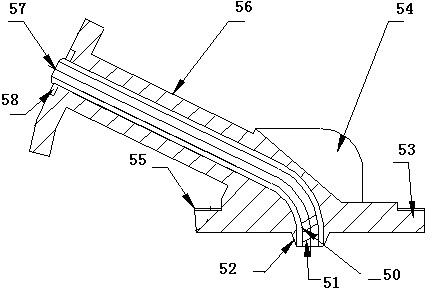

[0060] This embodiment is basically the same as Embodiment 1, the difference is: the rotating speed of the opening roller 2 is 8500r / min; the rotating speed of the rotor 3 is 60000r / min, and the negative pressure of the process is 6.8kpa; the twist of the yarn after twisting is 430 twists / m; the linear density of cooked strips is 420g / m; the dry uniformity CV% value of cooked strips 13 is 2.71; the arc-shaped flanging cotton inlet 10 is 15mm wide and 12mm high, and the curved cotton exit 14 is 10mm wide and 4mm high; The diameter of the zigzag combing roller is 64mm, and the number of combing teeth is 12 rows; the combining ratio is 100 times; the diameter of the rotor 3 is 40mm; is 30°, and the winding speed is 200m / min.

[0061] The quality of the 10 yarns produced in this embodiment reaches: the average breaking strength is 784cN, the breaking strength is 14.2cN / tex, and the evenness CVm% value is 10.5.

Embodiment 3

[0063] This embodiment is basically the same as Embodiment 1, and the difference is that the rotating speed of the opening roller 2 is 8500~8800r / min; the rotating speed of the rotor 3 is 62000r / min, and the process negative pressure is 6.85kpa; the twist of the yarn after twisting is 435 twists / m; cooked strip 13 linear density is 410g / m; cooked strip 13 dry uniformity CV% value is 2.73; arc-shaped flanging cotton inlet 10 is 16mm wide and 11.5mm high, and arc-shaped cotton outlet 14 is 9.5mm wide mm, height 3.5mm; the diameter of the zigzag opening roller is 64mm, and the number of opening teeth is 13 rows; the combination multiple is 105; the diameter of the rotor 3 is 40mm; mm; the winding angle is 32°, and the winding speed is 160m / min.

[0064] The quality of the 10 yarns produced in this embodiment reaches: the average breaking strength is 782.8cN, the breaking strength is 15.26cN / tex, and the evenness CVm% is 10.18.

[0065]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com