Enzyme-based magnetic nanoparticles, preparation method, application and detection method for glucose

A technology of magnetic nanoparticles and detection methods, applied in biochemical equipment and methods, determination/inspection of microorganisms, immobilization on or in inorganic carriers, etc., can solve problems such as poor effect and inactivation of biological enzymes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The preparation method of enzyme-based magnetic nanoparticles, the steps comprising:

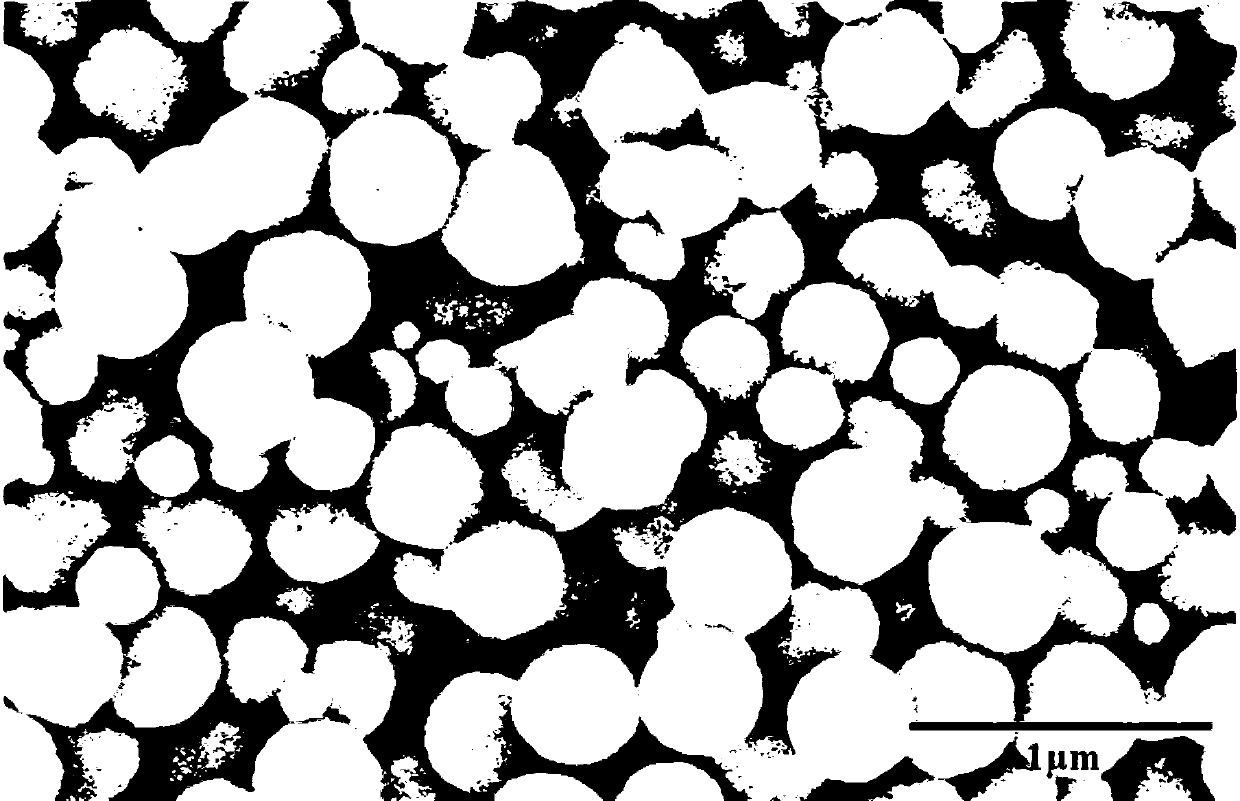

[0059] (1) Fe 3 o 4 Preparation of magnetic nanoparticles: take FeCl 3 ·6H 2 O, anhydrous sodium acetate, 1.0g polyethylene glycol was placed in ethylene glycol solution, stirred vigorously for 30 minutes, then transferred to an autoclave, reacted in an oven at 200°C for 8 hours, and cooled to room temperature; the synthesized After the product was washed with ethanol, it was dried in a vacuum oven for 6 hours to obtain Fe 3 o 4 magnetic nanoparticles;

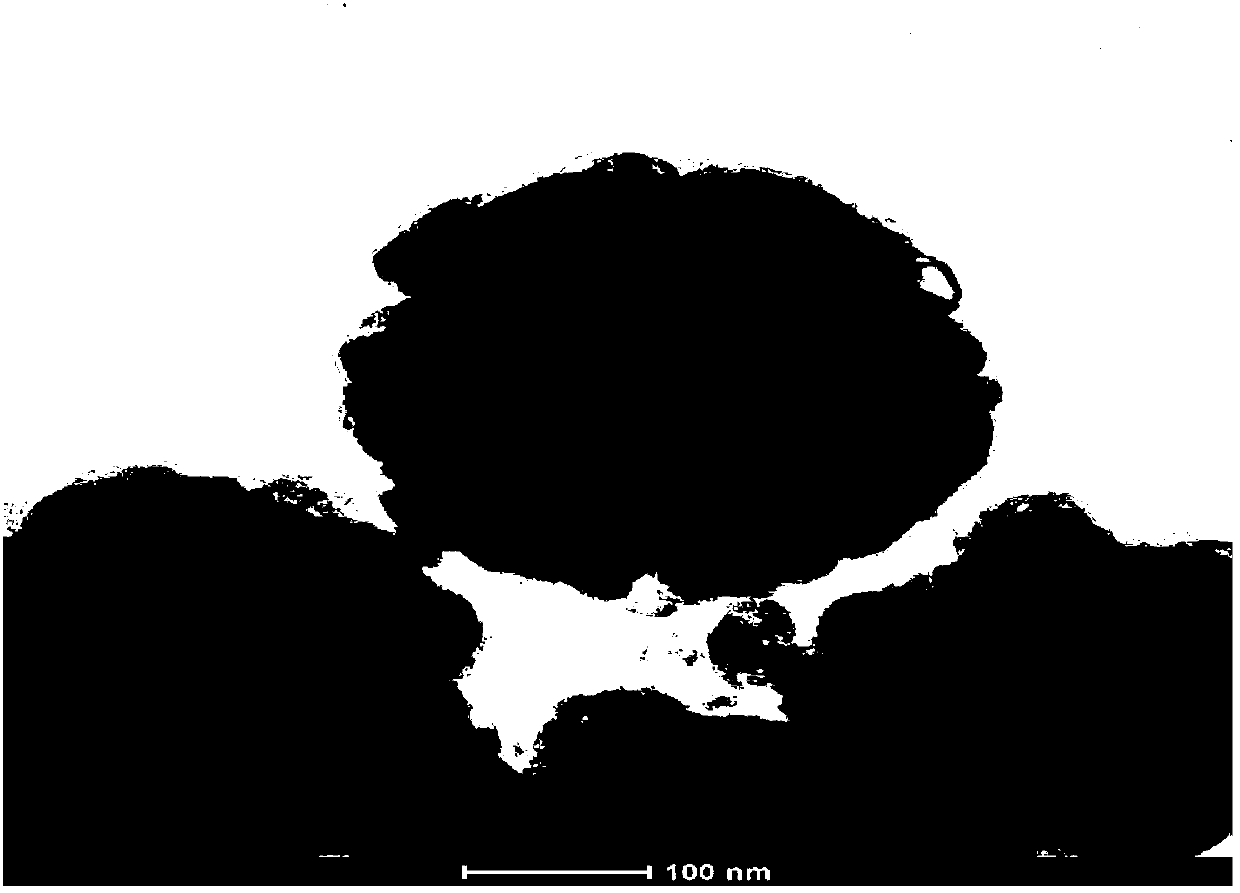

[0060] (2) Polydopamine (PDA) wrapped Fe 3 o 4 Preparation: 50mg of the above Fe 3 o 4 Dissolve magnetic nanoparticles and 100 mg of dopamine in 100 mL of water, add 60 mg of tris hydrochloride buffer (Tris-HCl buffer, concentration 0.05 mg / l, pH 8.5), stir for 24 hours at room temperature Wash with 50 mL of water and dry for 6 hours to obtain polydopamine-coated Fe 3 o 4 (PDAFe 3 o 4 );

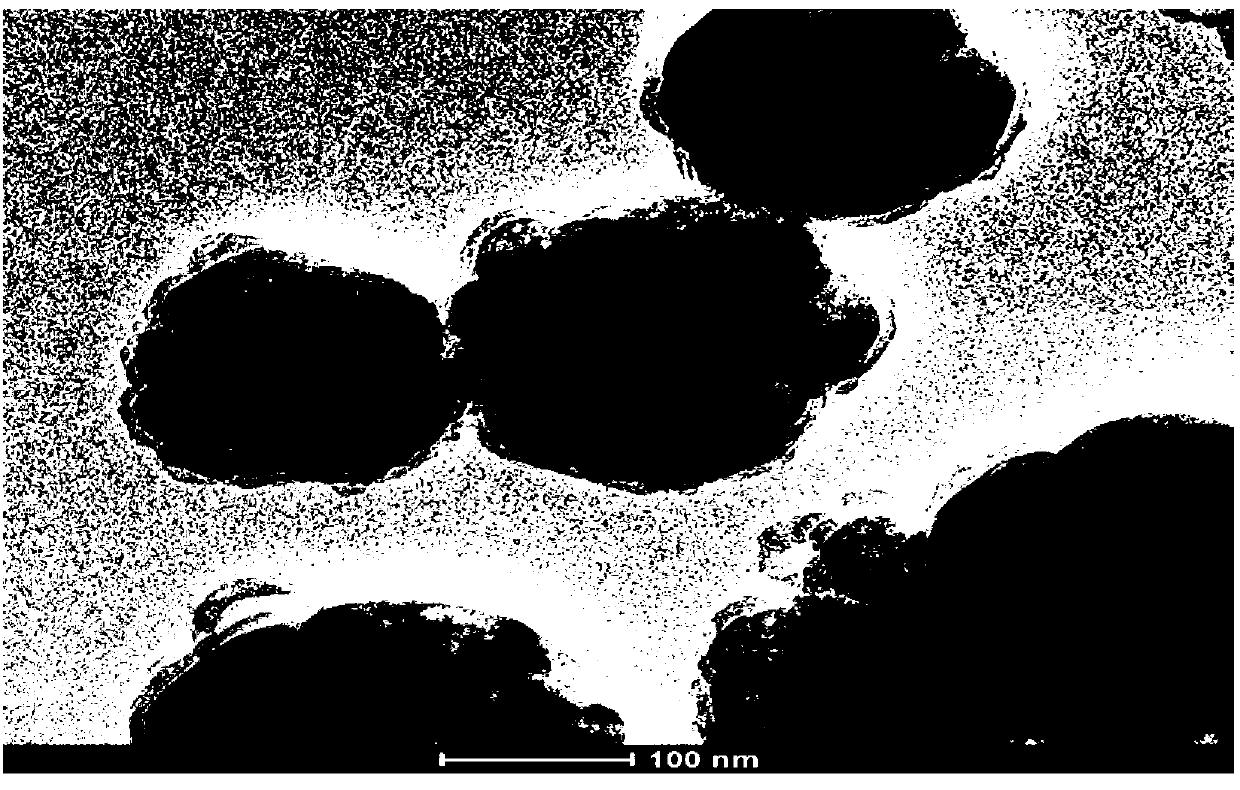

[0061] (3) 200 μL of horseradi...

Embodiment 2

[0064] (1) Fe 3 o 4 Preparation of magnetic nanoparticles: take FeCl 3 ·6H 2 O, anhydrous sodium acetate, 1.0 g of polyethylene glycol was placed in ethylene glycol solution, stirred vigorously for 30 minutes, then transferred to an autoclave, reacted in an oven at 200°C for 8 hours, and cooled to room temperature. Finally, after the synthesized product was washed with ethanol, it was dried in a vacuum oven for 6 hours;

[0065] (2) Polydopamine (PDA) wrapped Fe 3 o 4 Preparation: Fe 3 o 4 Dissolve magnetic nanoparticles and dopamine (DA) in water to obtain a mixed solution. The concentration of dopamine in the mixed solution is 0.5 mg / mL, and the percentage is the volume ratio of the mass of dopamine to water; in 100 mL of H 2 Add 5 mmol / L tris-hydroxymethylaminomethane solution in O to the mixed solution, then adjust the pH value of the mixed solution to 7.0 with 0.1 mol / L HCl solution; stir for 8 hours, and then use 10 mL of water Wash and dry in a vacuum oven for ...

Embodiment 3

[0068] (1) Fe 3 o 4 Preparation of magnetic nanoparticles: take FeCl 3 ·6H 2 O, anhydrous sodium acetate, 1.0 g of polyethylene glycol was placed in ethylene glycol solution, stirred vigorously for 30 minutes, then transferred to an autoclave, reacted in an oven at 200°C for 8 hours, and cooled to room temperature. Finally, after the synthesized product was washed with ethanol, it was dried in a vacuum oven for 6 hours;

[0069] (2) Polydopamine (PDA) wrapped Fe 3 o 4 Preparation: Fe 3 o 4 Dissolve magnetic nanoparticles and dopamine (DA) in water to obtain a mixed solution. The concentration of dopamine in the mixed solution is 1.0 mg / mL, and the percentage is the volume ratio of the mass of dopamine to water; in 100 mL of H 2 Obtain 5mmol / L tris-hydroxymethylaminomethane solution in O, add it to the mixed solution, and then adjust the pH value of the mixed solution to 8.0 with 0.1mol / L HCl solution; stir for 24 hours, and use 10-30mL washed with ethanol, and dried i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com