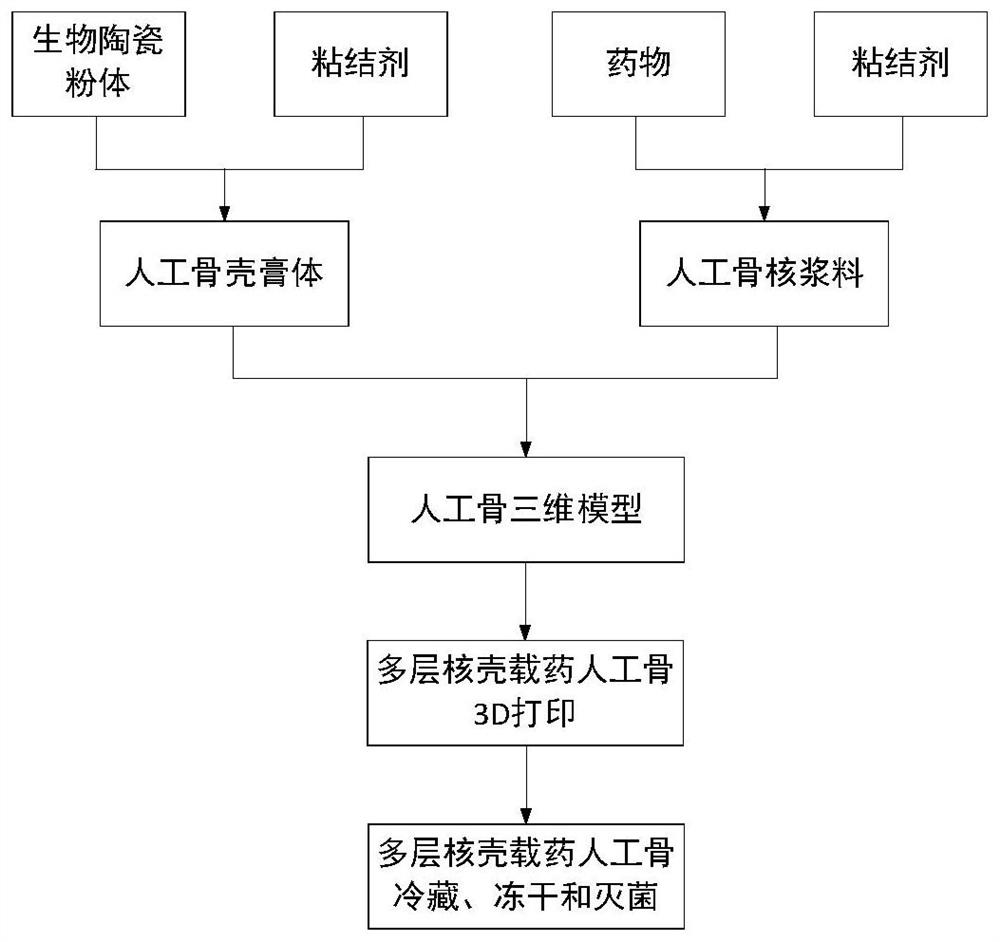

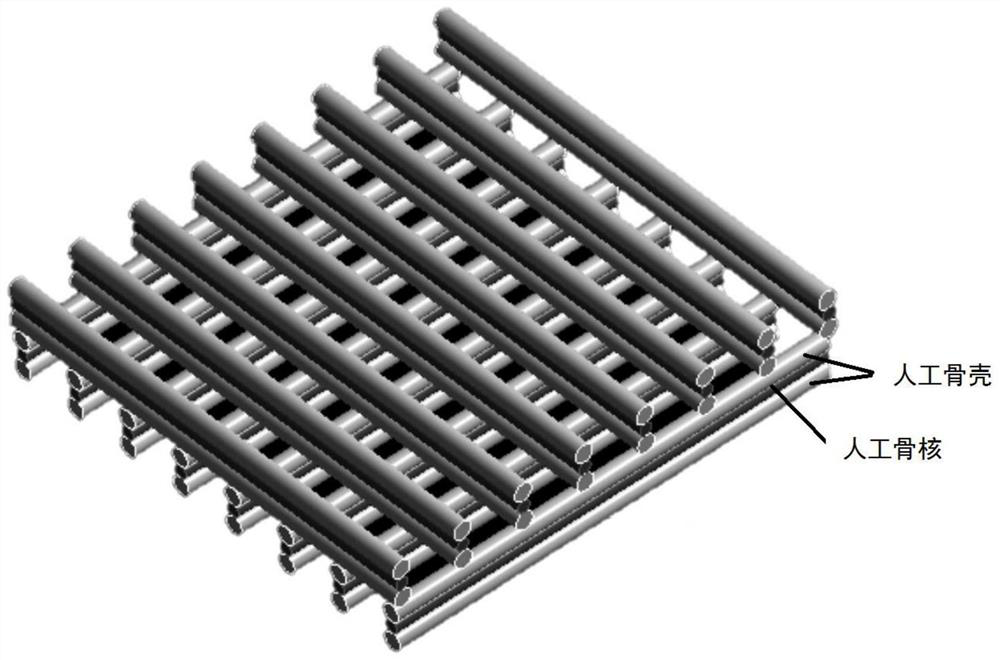

Drug-loaded artificial bone with multi-layer core-shell structure and preparation method of drug-loaded artificial bone

A multi-layer core-shell structure, artificial bone technology, applied in the medical field, can solve the problems of drug contamination, low strength of drug-loaded artificial bone, achieve no difference in performance, realize the diversity and individualization of drugs, and reduce the risk of infection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0049] (1) Preparation of binder: 10 g of polyvinyl alcohol and 90 g of sterilized water for injection are prepared into a 10% polyvinyl alcohol aqueous solution, placed in a jar with a lid, heated and swelled in a water bath at 60°C for 2 hours , and then stirred in a 96°C magnetic stirrer at a speed of 250r / min for 2h to completely dissolve and form a homogeneous solution;

[0050] (2) Preparation of drug-loaded artificial bone shell paste: mix hydroxyapatite and β-tricalcium phosphate at a mass ratio of 6:4, and then mix with binder solution at a mass ratio of 1:1, and set Stir in the mixer at a speed of 2000r / min for 4 times, each time for 1min, then put it into the barrel, and degas it in a homogenizer at a speed of 3000r / min for 2 times, each time at 2.5mim, to obtain a uniform shell printing paste body.

[0051] (3) Preparation of the drug-loaded artificial bone core slurry: mix the anti-tuberculosis drug amikacin and the binder solution at a mass ratio of 1:2, place i...

Embodiment example 2

[0059] (1) Preparation of binder: 6g of collagen and 94g of sterilized water for injection are mixed with a mass fraction of 6% collagen binder solution, placed in a jar with a lid, and placed in a magnetic stirrer with Stir at 300r / min for 1.5h to completely dissolve and form a uniform solution;

[0060] (2) Preparation of drug-loaded artificial bone shell paste: mix hydroxyapatite and binder solution at a mass ratio of 1:1.25, place in a mixer and stir at a speed of 2000r / min for 5 times, each time for 1min, Then put it into the barrel, and degas it in a homogenizer at a speed of 3000r / min for 4 times, each time 2mim, to obtain a uniform shell printing paste.

[0061] (3) Preparation of drug-loaded artificial bone core slurry: the antibiotic levofloxacin and penicillin V were mixed in a mass ratio of 1:1, and then mixed with the binder solution in a mass ratio of 1:1.5, and placed in a mixer at 2000rr. Stir at a speed of 1 / min for 5 times, each time for 20s, and then put it...

Embodiment example 3

[0068] (1) preparation binder: the chitosan of 8g and 92g sterilized water for injection are mixed with the chitosan aqueous solution that mass fraction is 8%, is placed in the jar with cover, in magnetic stirrer with 450r Stir at a speed of 1 / min for 1 hour to completely dissolve and form a homogeneous solution;

[0069] (2) Preparation of drug-loaded artificial bone shell paste: mix β-tricalcium phosphate and binder solution at a mass ratio of 1:1.5, place in a mixer and stir at a speed of 1500r / min for 3 times, each time for 2 minutes , and then put it into the barrel, degassing 5 times in a homogenizer at a speed of 1500r / min, 5mim each time, to obtain a uniform shell printing paste.

[0070] (3) Prepare drug-loaded artificial bone core slurry: mix the chemotherapeutic drug 5-fluorouracil and the binder solution at a mass ratio of 1:2, and then mix the chemotherapeutic drug mitoxantrone and the binder solution at a ratio of 1:1.25 The mass ratio was mixed, placed in a mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com