Integral replacing and hoisting method of steam generator of in-service nuclear power plant

A technology of a steam generator and a hoisting method, applied in the direction of a hoisting device, a hoisting device, etc., can solve the problems of large workload, increased equipment size and weight, and high risk, so as to meet the requirements of reducing working space and improving work efficiency. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the purpose of the invention, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

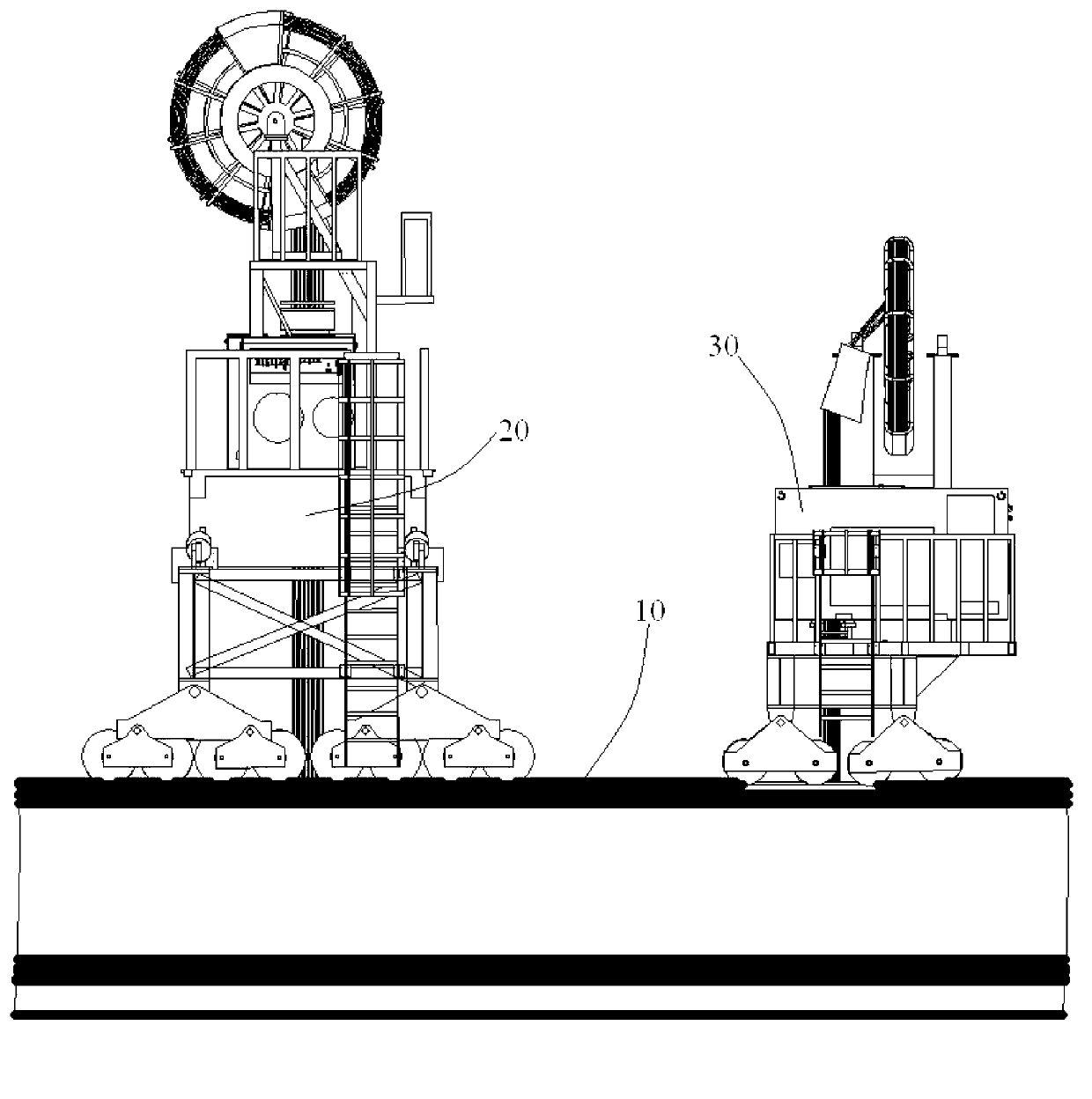

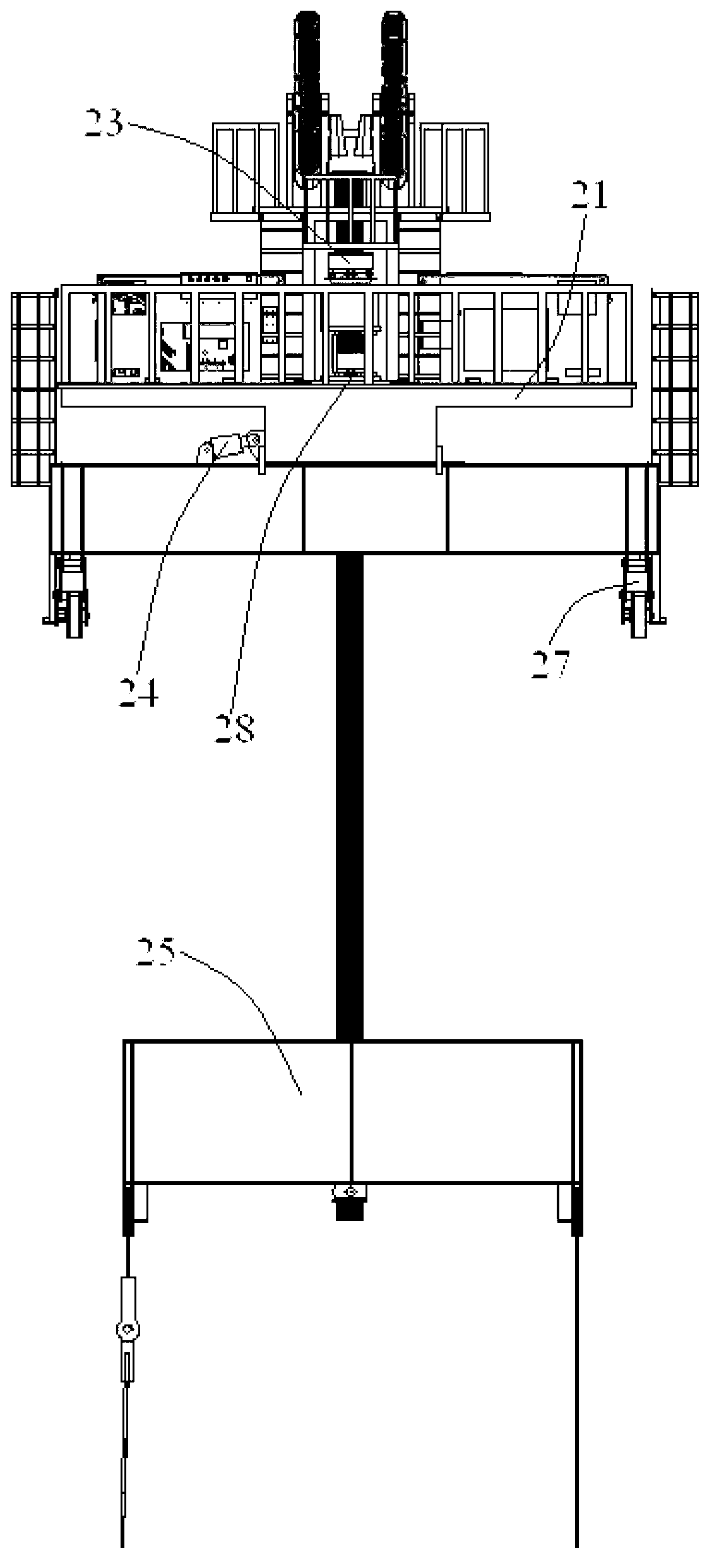

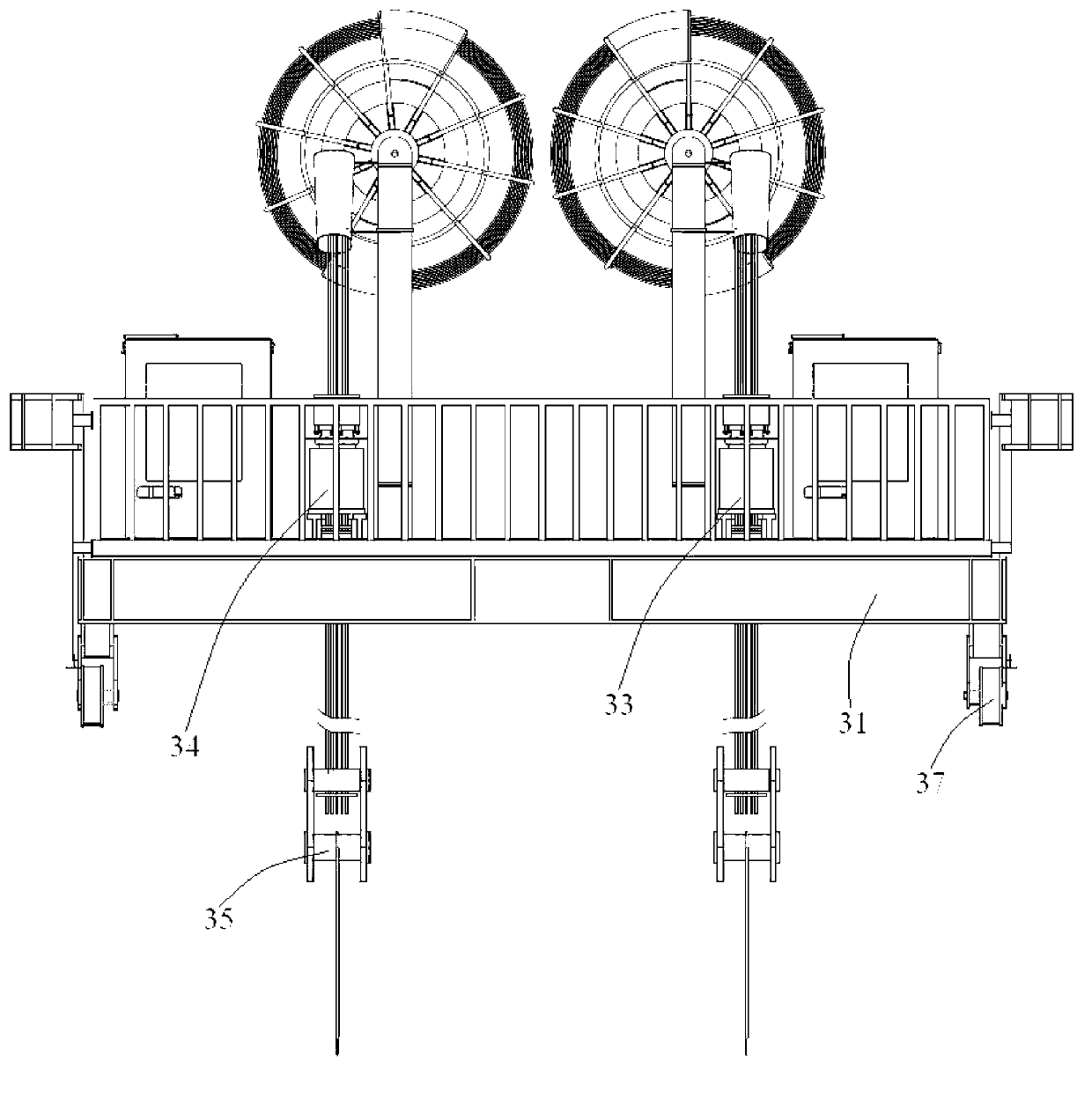

[0042] see figure 1 , in the overall replacement and hoisting method of the steam generator of the in-service nuclear power plant of the present invention, two hydraulic lifting devices 20, 30 arranged on the main girder 10 of the nuclear island ring crane are used to complete the aerial flip of the steam generator by lifting and hoisting or removal. Two hydraulic lifting devices 20, 30 are the main hydraulic lifting device 20 and the tail hydraulic lifting device 30 respectively.

[0043] According to the existing te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com