Targeted liposome drug delivery system used for tumor imaging, preparation method and application

A technology targeting liposome and drug delivery system, which is applied in the field of liposome drug delivery system and preparation of near-infrared fluorescent dyes, which can solve the problems of inconspicuous development, low signal intensity, and no expression, etc. Fluorescence signal intensity, high signal intensity, effect of increased distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

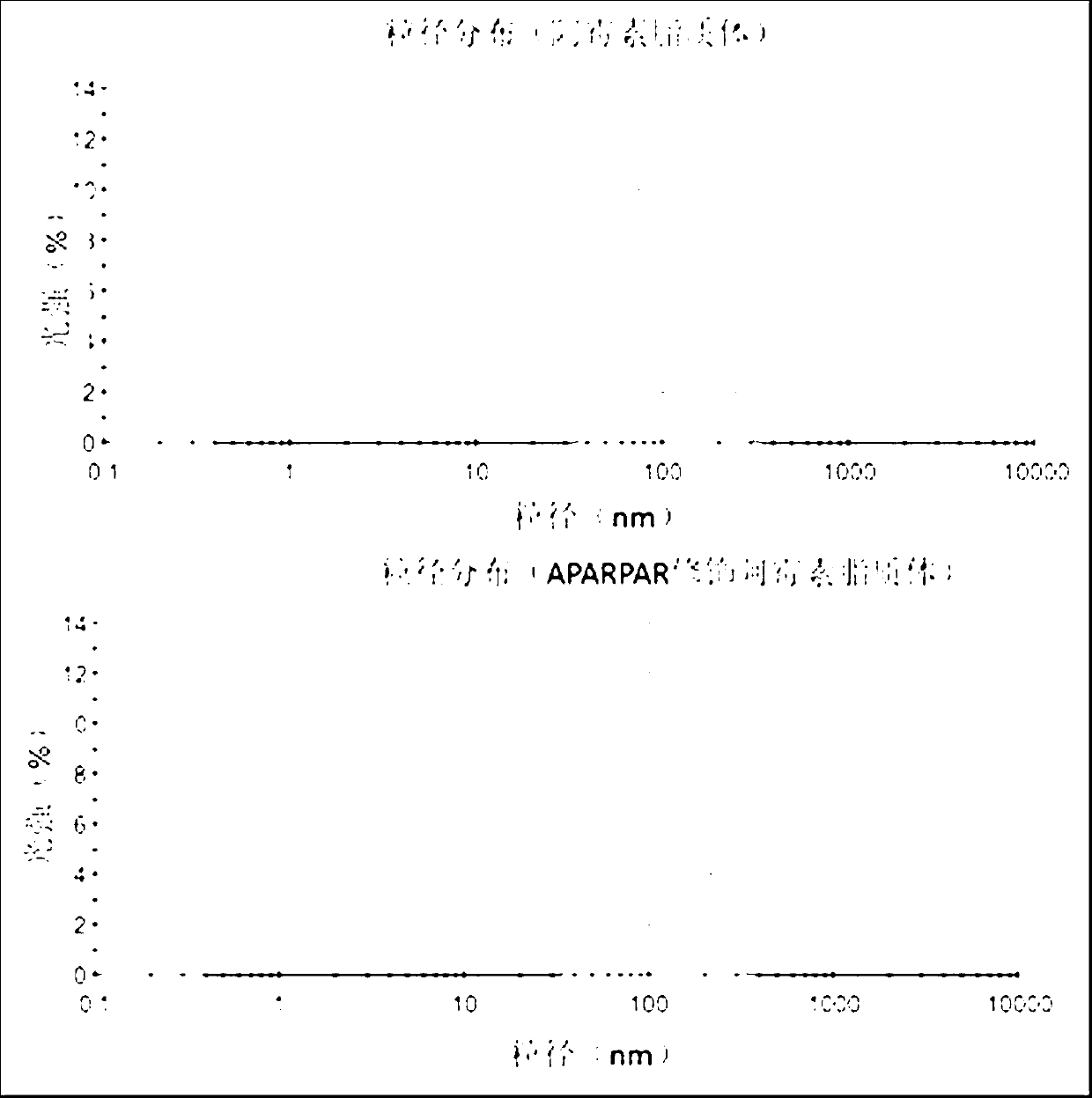

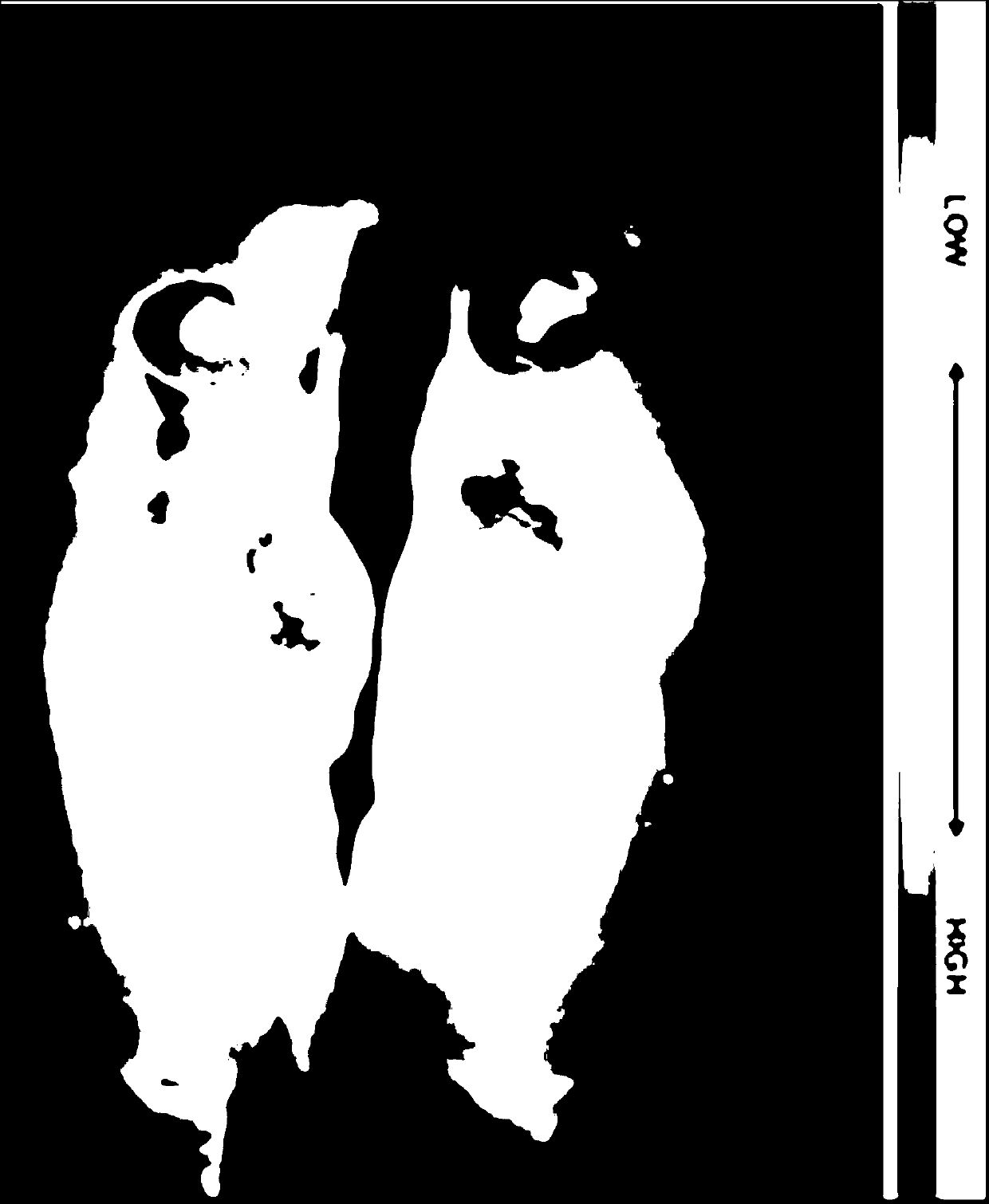

[0018] Example 1: Preparation and Characterization of RPAKPAR-Liposome / DiR.

[0019] The composition of the liposome membrane material formulation is HSPC (hydrogenated soybean phospholipid) / Chol (cholesterol) / mPEG-DSPE (polyethylene glycol-distearoylphosphatidylethanolamine complex) (50: 50: 2, mol / mol) , The PEG liposome membrane material modified by RPAKPAR is formulated as HSPC / Chol / mPEG-DSPE / RPAKPAR-PEG-DSPE (50: 50: 2: 0.5, mol / mol). Dissolve the above components in chloroform, add 30 μl of DiR methanol solution (1.5 mg / ml), remove the solvent by rotary evaporation, add physiological saline to the lipid film, ultrasonically disperse and rotate and oscillate in a water bath at 60 ° C to obtain DiR lipid body suspension. Thereafter, after heating to 60°C, a 50nm carbonate membrane can be directly extruded through the membrane to obtain liposomes of desired size. The particle size of the liposome was measured by dynamic light scattering method, and the result showed that ...

Embodiment 2

[0020] Example 2: Preparation and Characterization of RPAKPAR-Liposome / DiR.

[0021] The composition of the liposome membrane material formulation is HSPC (hydrogenated soybean phospholipid) / Chol (cholesterol) / mPEG-DSPE (polyethylene glycol-distearoylphosphatidylethanolamine complex) (55: 45: 2, mol / mol) , The PEG liposome membrane material modified by RPAKPAR is formulated as HSPC / Chol / mPEG-DSPE / RPAKPAR-PEG-DSPE (55: 45: 2: 0.5, mol / mol). Dissolve the above components in chloroform, add 30 μl of DiR methanol solution (1.5 mg / ml), remove the solvent by rotary evaporation, add physiological saline to the lipid film, ultrasonically disperse and rotate and oscillate in a water bath at 60 ° C to obtain DiR lipid body suspension. Thereafter, after heating to 60°C, a 50nm carbonate membrane can be directly extruded through the membrane to obtain liposomes of desired size. The particle size of the liposome was measured by dynamic light scattering method, and the result showed that ...

Embodiment 3

[0022] Example 3: Preparation and Characterization of RPAKPAR-Liposome / DiR.

[0023] The composition of the liposome membrane material formulation is HSPC (hydrogenated soybean phospholipid) / Chol (cholesterol) / mPEG-DSPE (polyethylene glycol-distearoylphosphatidylethanolamine complex) (55: 45: 2, mol / mol) , The PEG liposome membrane material modified by RPAKPAR is formulated as HSPC / Chol / mPEG-DSPE / RPAKPAR-PEG-DSPE (55: 45: 2: 0.5, mol / mol). Dissolve the above components in chloroform, add 10 μl of DiR methanol solution (1.5 mg / ml), remove the solvent by rotary evaporation, add physiological saline to the lipid film, ultrasonically disperse and rotate and oscillate in a water bath at 60 ° C to obtain DiR lipid body suspension. Thereafter, after heating to 60°C, a 50nm carbonate membrane can be directly extruded through the membrane to obtain liposomes of desired size. The particle size of the liposome was measured by dynamic light scattering method, and the result showed that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com